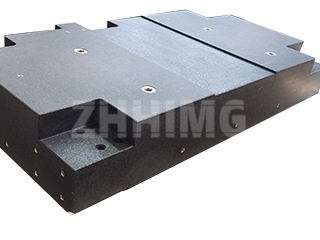

Icandelo lebhedi yomatshini wegranite limele inqanaba eliphezulu lokuzinza kwesakhiwo kwimveliso yanamhlanje. Ngenxa yokuqina kwayo okungaqhelekanga, ukudambisa ukungcangcazela okungokwemvelo, kunye ne-coefficient yokwandiswa kobushushu obuphantse bube zero, ezi nxalenye—ingakumbi ezo zenziwe ngezinto ezinoxinano oluphezulu ezifana ne-ZHHIMG® Black Granite yethu—ziyimfuneko kwiimashini ze-CNC zesizukulwana esilandelayo, izixhobo zokulinganisa ezichanekileyo kakhulu, kunye neenkqubo ze-laser eziphambili. Nangona kunjalo, ukusebenza kwezi nxalenye zichanekileyo oluphezulu kulungile kuphela njengokuseta kwazo kokuqala. Ukunamathela ngokucokisekileyo kwiiprotokholi zangaphambi kokufakwa kubalulekile ukuvula amandla apheleleyo kunye nokwandisa ubomi bokusebenza kwenkqubo yonke.

Uhambo oluya ngokuchanekileyo luqala ngesigaba sokuhlola esipheleleyo kunye nokulungiselela. Ngaphambi kokufakwa, icandelo kufuneka lidlule kuhlolo oluqinileyo olubonakalayo nolunemilinganiselo. Iinjineli kufuneka zijonge ngononophelo umphezulu wegranite ukuba azinazo naziphi na iintanda ezincinci, ukuqhekeka, okanye umonakalo wokuphatha onokwenzeka ngexesha lokuhamba. Okubaluleke ngakumbi, ubukhulu obuqinisekisiweyo becandelo kunye nokuchaneka kwejometri—ukuthe tyaba, isikwere, kunye nokuhambelana—kufuneka kuqinisekiswe kwakhona kusetyenziswa izixhobo zemetrology eziphambili, ukuqinisekisa ukuba ibhedi iyahlangabezana nokunyamezelana kokucubungula okanye ukulinganisa okucetywayo. Kwangaxeshanye, uvavanyo lokusingqongileyo lubalulekile. Njengomthengisi wehlabathi, i-ZHHIMG® ifuna abasebenzisi ukuba baqinisekise ukuba indawo yokufaka ihambelana nemilinganiselo yobushushu kunye nokufuma okungqongqo, ikhusela uzinzo lwexesha elide lwegranite kwiimeko ezimbi ngaphambi kokuba inkqubo yokuhlanganisa iqale.

Ngexesha lenkqubo yokufakela, ulawulo lwesiseko lubaluleke kakhulu. Isiseko esamkelayo kufuneka sibe ngqongqo, sibe semgangathweni opheleleyo, kwaye sahlulwe kwiintshukumo ezinokubakho kunye nemiba yokusombulula. Nakuphi na ukungangqinelani kwisiseko kuya kufaka uxinzelelo lwangaphakathi kwi-granite, ethi, nangona inamandla, ichaphazele ubunyani bayo bokugqibela. Izixhobo zokulinganisa ngokuchanekileyo kunye nee-shims kufuneka zisetyenziswe ukulawula ngononophelo ulungelelwaniso oluthe tye, ngelixa izalathisi ezibalulekileyo ezifana nokuma ngxi kunye nokuhambelana kufuneka zilawulwe kwinqanaba le-sub-micron, zibonisa imigangatho echanekileyo yendawo yethu yokuvelisa. Ngaphezu koko, ukudibana kunye nokuqiniswa kwebhedi ye-granite kulo lonke ulwakhiwo lomatshini kufuna ulwazi olukhethekileyo. Kufuneka kusetyenziswe izibophelelo kunye neearhente zokubopha ezilinganiswe ngokuchanekileyo, kusetyenziswa amaxabiso athile e-torque ukuqinisekisa uqhagamshelo oluqinileyo noluzinzileyo ngaphandle kokufaka uxinzelelo olugqithisileyo lwangaphakathi olunokonakalisa i-granite okanye luphazamise i-geometry yayo echanekileyo.

Ngaphambi kokuba inkqubo inikezelwe kwimveliso, isigaba esipheleleyo sokugunyazisa nokuvavanya siyimfuneko. Eli nqanaba libandakanya uvavanyo olusebenzayo lwazo zonke iindawo ezihambayo ezidityanisiweyo, njengezikhokelo ezithe tye kunye neenkqubo zokuqhuba, ukuqinisekisa intshukumo egudileyo, engenaziphazamiso ngaphandle kwengxolo yokubopha okanye engaqhelekanga. Oku kulandelwa kwangoko kukuqinisekiswa kokuchaneka kwenkqubo yokugqibela. Ukusebenzisa izixhobo zokulinganisa ezilandelekayo—ezifana nezo zivela kumaqabane ethu afana noRenishaw kunye noWYLER—ukuchaneka kwejometri iyonke yomatshini odibeneyo kufuneka kuqinisekiswe ngokuchasene neeparamitha zokusebenza ezichaziweyo. Nakuphi na ukuphambuka kufuneka kuhlalutywe kwaye kulungiswe ngoko nangoko, kuqinisekiswe ukuba izixhobo ziyahambelana nemigangatho efana neGerman DIN okanye i-US ASME ngaphambi kokuba kucutshungulwe naziphi na izixhobo. Okokugqibela, iinkqubo zokhuseleko zokusebenza kufuneka zihlolwe, kwaye abasebenzi kufuneka bafumane uqeqesho olupheleleyo malunga neenkqubo zokuphatha kunye nokhuseleko ezifunekayo kumatshini ochanekileyo.

Into yokugqibela yokucwangcisa ukusetyenziswa kwangaphambili sisicwangciso sokulungisa. Nangona i-granite yaziwa ngokuqina kwayo, ukhathalelo olufanelekileyo luqinisekisa ixesha layo elide. Ishedyuli yokucoca rhoqo kusetyenziswa amalaphu athambileyo kuphela kunye nezicoci ezingathathi cala kufuneka imiselwe, nto leyo ethintela ngokucacileyo izixhobo ezirhabaxa ezinokukrwela umphezulu oneentambo ezichanekileyo. Okubaluleke ngakumbi, inkqubo yokuthambisa izixhobo zoomatshini kunye nokuphatha iindawo zentsimbi ezibonakalayo ukuze kuthintelwe umhlwa kufuneka iphunyezwe. Ngokulandela ngononophelo le migaqo ipheleleyo yokufakela kwangaphambili kunye nokusetyenziswa kwangaphambili, abavelisi baqinisekisa ukuba i-ZHHIMG® Granite Machine Bed Component inika ukusebenza okugqwesileyo, ubomi benkonzo ende, kunye nozinzo olungagungqiyo eyayilelwe ukubonelela ngalo.

Ixesha leposi: Novemba-17-2025