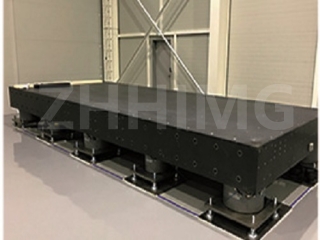

I-Granite yinto ethandwayo kwiiplatifomu zeemoto ezithe ngqo ngenxa yokwakheka kwayo okwahlukileyo kwezinto. Ukwakheka kwe-granite, equka i-quartz, i-feldspar, kunye ne-mica, kudlala indima ebalulekileyo ekumiseleni ukufaneleka kwayo kwiiplatifomu zeemoto ezithe ngqo.

Ubukho be-quartz kwi-granite buyinika ubulukhuni obumangalisayo kunye nokuqina, nto leyo eyenza ukuba ibe yinto efanelekileyo kwiiplatifomu zeemoto ezithe ngqo. Ubulukhuni be-quartz buqinisekisa ukuba umphezulu we-granite unokumelana namanqanaba aphezulu oxinzelelo kunye noxinzelelo olukhutshwa zii-motor ezithe ngqo. Olu phawu lubalulekile ekuqinisekiseni uzinzo kunye nobude beplatifomu yeemoto ezithe ngqo.

Ukongeza, umxholo we-feldspar kwi-granite unegalelo ekubeni ikwazi ukumelana nokuguguleka. Iiplatifomu zeemoto ezizii-linear zihlala zishukunyiswa kwaye zingqubana, kwaye ubukho be-feldspar bunceda i-granite igcine ulwakhiwo lwayo ngokuhamba kwexesha. Oku kubalulekile ukuqinisekisa ukusebenza kakuhle nokuthembekileyo kweeplatifomu zeemoto ezizii-linear kwizicelo ezahlukeneyo zoshishino nezorhwebo.

Ngaphezu koko, umxholo we-mica kwi-granite uyinika iipropati ezintle zokukhusela umbane. Oku kubaluleke kakhulu kwiiplatifomu zeemoto ezithe ngqo, njengoko kunceda ukuthintela ukuphazamiseka kombane kwaye kuqinisekisa ukusebenza kakuhle kweemoto. Amandla e-granite okukhusela ngokufanelekileyo umbane kwimijelo yombane enza ukuba ibe lukhetho olukhethwayo kwiiplatifomu zeemoto ezithe ngqo kwizicelo zobunjineli be-elektroniki nobungcali.

Ukuqukumbela, ukwakheka kwezinto zegranite, ingakumbi ubukho be-quartz, i-feldspar, kunye ne-mica, kunefuthe elikhulu ekufanelekileni kwayo kwiiplatifomu zeemoto ezithe ngqo. Ukudibana kobulukhuni, ukumelana nokuguguleka, kunye neempawu zokufakelwa kombane kwenza igranite ibe yinto efanelekileyo yokuxhasa iimfuno zokusebenza okuphezulu kweeplatifomu zeemoto ezithe ngqo. Amandla ayo okumelana noxinzelelo, ukugcina ulungelelwaniso lwesakhiwo, kunye nokubonelela ngokufakelwa kombane kwenza igranite ibe lukhetho oluthembekileyo noluhlala ixesha elide kwiiplatifomu zeemoto ezithe ngqo kumashishini ahlukeneyo.

Ixesha leposi: Julayi-08-2024