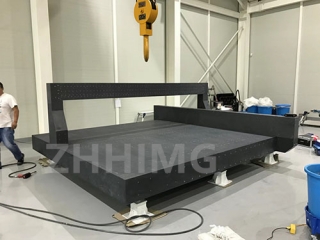

Kwicandelo lokulinganisa ngokuchanekileyo, ukuzinza kwesiseko sezixhobo zokulinganisa kumisela ngokuthe ngqo ukuthembeka kwedatha. Ingxaki yempazamo yokulinganisa ebangelwa kukuguquka kobushushu beziseko zesinyithi esityhidiweyo ibisoloko ichaphazela ishishini lokuvelisa. Nangona kunjalo, iqonga lesixhobo sokulinganisa i-granite flatness elaqaliswa yi-ZHHIMG, elinesatifikethi sayo sokuchaneka kwinqanaba le-AAA esidlula imigangatho yoshishino, libonelela ngesisombululo esiguqukayo sokulinganisa ngokuchanekileyo okuphezulu.

Ingxaki yokuguqulwa kobushushu kwiziseko zesinyithi: Umbulali Ongabonakaliyo weempazamo zokulinganisa

Iziseko zesinyithi esitshisiweyo zazisetyenziswa kakhulu kwizixhobo zokulinganisa ngenxa yexabiso lazo eliphantsi kunye nokuqina kwazo okunamandla. Nangona kunjalo, kwiindlela ezisebenzayo, ingxaki yokuzinza kwazo okuphantsi kobushushu iye yavela kancinci kancinci. I-coefficient yokwandiswa kobushushu besinyithi esitshisiweyo iphezulu njenge-11-12 × 10⁻⁶/℃. Xa izixhobo zisebenza okanye ubushushu obujikeleze umhlaba butshintshatshintsha, kulula kakhulu ukuba zitshintshe ubushushu. Umzekelo, xa ubushushu obujikeleze umhlaba kwindawo yokusebenzela butshintsha nge-5℃, isiseko sesinyithi esitshisiweyo sinokuguquka ngokuthe ngqo kwe-0.0055-0.006mm. Utshintsho oluncinci olunjalo luya kubangela ngokuthe ngqo ukuba ireferensi yokulinganisa itshintshe, iphindaphinde impazamo yokulinganisa.

Ukongeza, ukuhanjiswa kobushushu kwesiseko sesinyithi esityhidiweyo akulunganga. Xa izixhobo zisebenza, ukufudumeza kwendawo kuya kubangela "isiphumo se-thermal gradient", okubangela ukugqwetheka kunye nokuguquguquka kumphezulu wesiseko. Ekulinganisweni kokuthe tyaba, olu tshintsho lunokubangela ukuphambuka kwindawo ehambelanayo phakathi kweprobe yokulinganisa kunye nento elinganiswayo, ekugqibeleni kuphume idatha yokulinganisa engachanekanga. Ngokwezibalo-manani zoshishino, kwizixhobo zokulinganisa ezineziseko zesinyithi esityhidiweyo, iimpazamo ezibangelwa kukuguquguquka kobushushu zibangela ngaphezulu kwama-40% eempazamo zizonke, zichaphazela kakhulu ukuchaneka kokuhlolwa komgangatho wemveliso.

Inkqubela phambili kwezobuchwepheshe kwiqonga le-granite le-ZHHIMG: Ukususa ukuguquguquka kobushushu kwiingcambu

Iqonga lesixhobo sokulinganisa ubume begranite ye-ZHHIMG lithatha igranite yendalo njengesixhobo esisisiseko, lisombulula ingxaki yokuguquguquka kobushushu ukusuka kwisiseko sezinto. I-coefficient yokwandiswa kobushushu begranite yi-5-7 × 10⁻⁶/℃ kuphela, eyisiqingatha kuphela sesinyithi esityhidiweyo. Ngaphezu koko, ulwakhiwo lwayo lwangaphakathi luxinene kwaye luyafana. Nokuba phantsi kotshintsho olukhulu lobushushu, inokugcina ubungakanani kunye nemilo ezinzileyo. Idatha yelabhoratri ibonisa ukuba kwindawo enokuguquguquka kobushushu kwe-20℃, ukuguqulwa okuthe ngqo kweqonga legranite kungaphantsi kwe-0.0014mm, into ephantse ingabi namsebenzi.

Ukongeza kwiingenelo zezinto eziphathekayo, i-ZHHIMG isebenzisa itekhnoloji yokucubungula enelungelo lobunikazi elichanekileyo. Ngokusebenzisa iindlela zokugaya nokupolisha ze-CNC, ubucaba bomphezulu weqonga buyandiswa bufikelele kwi-±0.001mm/m2, bufikelele kwinqanaba eliphezulu kushishino. Okwangoku, isakhiwo sokukhulula uxinzelelo esifana nehoneycomb sakhiwe ngaphakathi kweqonga, esiphucula ngakumbi ubulukhuni ngelixa sisasaza ngokufanelekileyo ukuguquguquka kwemizuzu okubangelwa luxinzelelo lobushushu, siqinisekisa ukuba isalathiso sokulinganisa sihlala sizinzile kwaye sithembekile ngamaxesha onke.

Isiqinisekiso sokuchaneka kwenqanaba le-Aaa: Ukuzinikela komgangatho oxhaswa ligunya

Iqonga legranite le-ZHHIMG liphumelele isiqinisekiso sokuchaneka kwenqanaba le-AAA liziko eligunyazisiweyo lamazwe ngamazwe. Lo mgangatho wesiqinisekiso ufuna ukuba impazamo yokulinganisa yezixhobo ihlale ilawulwa ngaphakathi kwe-±0.3μm phantsi kotshintsho oluninzi lokusingqongileyo olufana nobushushu, ukufuma kunye nokungcangcazela. Ukuze kuhlangatyezwane nalo mgangatho, i-ZHHIMG iseke inkqubo yolawulo lomgangatho olupheleleyo: ukusuka ekuhlolweni kwe-ore yegranite eluhlaza, ukucutshungulwa ngokuchanekileyo ukuya ekuhlolweni kweemveliso ezigqityiweyo, ikhonkco ngalinye lijongwa ngokungqongqo zizixhobo zokuhlola ezenzekelayo. Umzekelo, i-interferometer yelaser isetyenziselwa ukwenza ukuskena kwenqanaba le-micron yomphezulu weqonga ukuqinisekisa ukuba impazamo yokuthamba iyalungiswa. Uzinzo lobushushu beqonga luqinisekiswa ngokulinganisa iindawo ezigqithisileyo ngelebhu yobushushu kunye nokufuma engaguqukiyo.

Kwizicelo ezisebenzayo, iqonga le-ZHHIMG libonakalise iingenelo ezibalulekileyo kumashishini afana nee-semiconductors, iilensi ze-optical, kunye nee-precision molds. Emva kokuba ishishini elithile le-semiconductor lizise eli qonga, impazamo yokulinganisa ubucaba yancitshiswa ngama-90%, kwaye izinga lemveliso lenyuswa nge-15%, nto leyo ethetha ngempumelelo ingxaki yokuphinda ilungiswe ebangelwe ziimpazamo zokulinganisa.

Ngokuchasene nophuculo lweshishini lokuvelisa oluya kutsho ekuchanekeni okuphezulu nasebukrelekreleni, iqonga lesixhobo sokulinganisa ubume begranite ye-ZHHIMG lichaze ngokutsha umgangatho wokulinganisa ngokuchanekileyo ngolawulo lwalo olupheleleyo lokuguquguquka kobushushu kunye nesatifikethi sokuchaneka kwenqanaba le-AAA. Ayiboneleli nje kuphela ngeziqinisekiso zokulinganisa ezithembekileyo kumashishini, kodwa ikwakhuthaza ukutsiba kwetekhnoloji yeshishini ukusuka "kwisigqibo esibonakalayo" ukuya "ekufumaneni ngokuchanekileyo".

Ixesha leposi: Meyi-12-2025