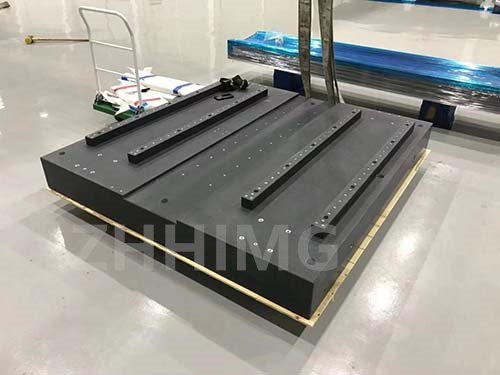

Kwicandelo lokuvelisa ngokuchanekileyo, ukubophelela nge-laser kufuna ukuchaneka okucacileyo ukuqinisekisa ukuthembeka nokusebenza kwezinto ezibophelelekileyo. Iziseko zoomatshini be-granite, ingakumbi ezo zivela kubaboneleli abathembekileyo abanjengoZHHIMG®, zidlala indima ebalulekileyo ekufezekiseni ezi ziphumo zichanekileyo. Nantsi indlela iimpawu zabo ezizodwa eziphucula ngayo ukusebenza kwezixhobo zokubophelela nge-laser.

Uzinzo Olungenakuthelekiswa Nanto Lokulungelelanisa Ngokuhambelanayo

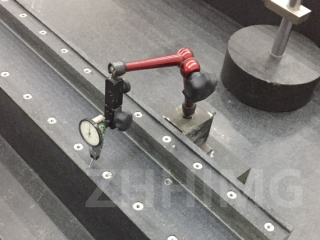

Ukubopha nge-laser kufuna ukuba izinto zihlale zilungelelene ngokugqibeleleyo kuyo yonke le nkqubo. Iziseko zomatshini we-granite, ezinobunzima obuphezulu obumalunga ne-3100 kg/m³, zibonelela ngesiseko esizinzileyo kakhulu. Ubunzima kunye nokuqina kwe-granite kumelana namandla angaphandle anokubangela ukuba izixhobo zokubopha zitshintshe okanye zithambe. Nokuba kukungcangcazela okuvela kumatshini akufutshane okanye ukuhamba kwabaqhubi kumgangatho wefektri, isiseko esizinzileyo siqinisekisa ukuba umthombo we-laser kunye neqonga lokubopha ligcina izikhundla zazo ezichanekileyo. Olu zinzo lubalulekile ekufezekiseni umgangatho wokubopha ohambelanayo, njengoko nokuba ukungalungelelani okuncinci kunokukhokelela kumalungu abuthathaka okanye ukungaphumeleli kokubopha.

Ukudambisa ukungcangcazela okuphezulu kwimpazamo - Ukubopha ngokukhululekileyo

Iipulse zamandla aphezulu zeeleser kwimisebenzi yokubopha zinokuvelisa ukungcangcazela kwangaphakathi ngaphakathi kwezixhobo. Ukongeza, ukungcangcazela okujikelezayo okuvela kwindawo yokuvelisa kuyingozi enkulu ekuchaneni. Amandla okungcangcazela kwendalo eGranite atshintsha umdlalo kule meko. Ulwakhiwo lwayo lwangaphakathi olukhethekileyo, oluqulunqwe ziinkozo zezimbiwa ezidibeneyo, lufunxa kwaye lusasaze amandla okungcangcazela ngempumelelo. Ngokunciphisa oku kungcangcazela, iziseko zomatshini wegranite zithintela umqadi welaser ekuphambukeni kwithagethi. Ngenxa yoko, inkqubo yokubopha inokwenzeka ngokuchaneka okukhulu, inciphisa umngcipheko wokusasazwa kobushushu okungalinganiyo kwaye iqinisekise amandla ebhondi afanayo kulo lonke ilungu.

Ukumelana Okumangalisayo Nobushushu Bokugcina Ngobunono

Ukuguquguquka kobushushu akunakuphepheka kwiindawo zokwenza imveliso, kwaye kunokuba nefuthe elikhulu ekuchanekeni kokubopha nge-laser. I-Granite's thermal expansion coefficient ephantsi yeyona nzuzo iphambili apha. Ngokungafaniyo neentsimbi ezininzi ezikhula kwaye zinciphe kakhulu ngotshintsho lobushushu, i-granite igcina ubukhulu bayo naphantsi kweemeko ezahlukeneyo zobushushu. Kwi-laser bonding, apho uzinzo lobushushu lubalulekile ukugcina izinto ezibonakalayo zilungelelene kwaye kuthintelwe uxinzelelo lobushushu kwizinto ezibotshelelweyo, isiseko somatshini we-granite sisebenza njengesikhuseli. Siqinisekisa ukuba indawo ephambili ye-laser ihlala ihleli kwaye indawo yezixhobo ayitshintshi ngenxa yobushushu, ngaloo ndlela ivumela iziphumo zokubopha ezichanekileyo neziphindaphindwayo.

Ukungaqini kweekhemikhali ukuze kuqinisekiswe ukuthembeka kwexesha elide

Ukubopha nge-laser kunokubandakanya ukusetyenziswa kweekhemikhali ezahlukeneyo ukulungiselela umphezulu okanye ukuphucula inkqubo. Ukungangeni kweekhemikhali zeGranite kuyenza imelane nokugqwala kwezi zinto. Le propati ikhusela ukuthembeka kwesiseko somatshini ngokuhamba kwexesha, iqinisekisa ukuba iyaqhubeka nokubonelela ngeqonga elizinzileyo nelichanekileyo lemisebenzi yokubopha nge-laser. Ngokukhetha isiseko somatshini segranite, abavelisi banokuphepha imiba enokubakho enxulumene nokuwohloka okubangelwa ziikhemikhali, njengokugoba okanye ubuthathaka bezinto ezisisiseko, okunokuphazamisa ukuchaneka kwenkqubo yokubopha.

Ukuqukumbela, iziseko zomatshini wegranite zibalulekile ekufezekiseni iziphumo ezichanekileyo zokubopha nge-laser. Uzinzo lwazo, ukungcangcazela - ukudambisa, ukumelana nobushushu, kunye nokungangeni kweekhemikhali zisebenza ngokuhambelanayo ukudala imeko-bume efanelekileyo yokubopha ngokuchanekileyo okuphezulu. Xa ufuna ukuphucula umgangatho kunye nokuthembeka kwemisebenzi yokubopha nge-laser, ukutyala imali kwisiseko somatshini wegranite esikumgangatho ophezulu, njengaleyo inikezelwa yi-ZHHIMG®, sisigqibo esicwangcisiweyo esihlawula izabelo ngendlela yeziphumo zokubopha ezihambelanayo, ezichanekileyo, nezingenaziphene.

Ixesha lokuthumela: Juni-03-2025