Kwicandelo elichanekileyo kakhulu lokwenziwa kwee-semiconductor, nokuba kungcangcazela okuncinci kunokuchaphazela kakhulu ukusebenza koomatshini bokufaka ii-wafer, okukhokelela kwiziphene kunye nokulahlekelwa yimveliso. Iziseko zoomatshini be-granite ziye zavela njengesisombululo esitshintsha umdlalo, zibonelela ngezakhono zokunciphisa ukungcangcazela ezingenakuthelekiswa nanto ezibalulekileyo ekugcineni ukuthembeka kokucubungula ii-wafer.

Uxinano Oluphezulu kunye ne-Inertia yokunciphisa ukungcangcazela

Uxinano oluphezulu lweGranite, oluqhele ukuba phakathi kwe-2,600 ukuya kwi-3,100 kg/m³, lubonelela nge-inertia enkulu. Xa ludityaniswe noomatshini bokufaka i-wafer, olu phawu lumelana nokungcangcazela kwangaphandle ngokufanelekileyo. Umzekelo, kumgangatho wefektri oxakekileyo we-semiconductor, oomatshini abajikelezileyo kunye nokuhamba ngeenyawo kunokuvelisa ukungcangcazela okujikelezayo. Isiseko somatshini wegranite, ngobunzima baso obunzima, sisebenza njengesiseko esizinzileyo, sinciphisa ukudluliselwa kwezi ngcangcazela kwiindawo ezibuthathaka zomatshini wokufaka i-slot. Ngenxa yoko, izixhobo zokusika zihlala zibekwe ngokuchanekileyo, zinciphisa umngcipheko wokunqunyulwa okungafunekiyo kwaye ziphucula umgangatho uwonke wee-wafers ezifakwe i-slot.

Ukungcangcazela kwendalo - Iipropati zokufutha

Ulwakhiwo lwangaphakathi olulodwa lwegranite, olwenziwe ziinkozo zeminerali ezidibeneyo, luyinika amandla amahle kakhulu okungcangcazela - ukufunxa. Xa umatshini wokuqhekeza i-wafer usebenza, ukujikeleza ngesantya esiphezulu kwezixhobo zokusika kunye namandla oomatshini abandakanyekayo kunokuvelisa ukungcangcazela kwangaphakathi. Igranite ifunxa kwaye ichithe la mandla okungcangcazela, iwathintele ekubeni ajikeleze isakhiwo somatshini. Ngokungafaniyo neziseko zesinyithi ezinokwandisa ukungcangcazela, isiphumo sendalo sokufunxa igranite siqinisekisa ukuba umatshini usebenza kakuhle. Uphando lubonisa ukuba ukusebenzisa iziseko zegranite kunokunciphisa i-vibration amplitudes ukuya kuthi ga kwi-70%, okwenza umatshini wokuqhekeza ugcine inqanaba eliphezulu lokuchaneka ngexesha lenkqubo yokusika.

Uzinzo lobushushu ukuze kuthintelwe ukungcangcazela - Iimpazamo ezibangelwayo

Ukutshintshatshintsha kobushushu kwindawo yokuvelisa kunokubangela ukuba izinto zande okanye zinciphe, nto leyo ekhokelela ekungalungelelaniseni nasekungcangcazeleni okulandelayo. I-Granite inomlinganiselo ophantsi wokwanda kobushushu, oko kuthetha ukuba igcina imo yayo kunye nobukhulu bayo naphantsi kobushushu obahlukeneyo. Kumatshini wokufaka i-wafer, olu zinzo lobushushu lubalulekile. Umzekelo, ngexesha lokwenziwa kwexesha elide, umatshini unokufudumala ngenxa yokusebenza okuqhubekayo. Isiseko se-granite siqinisekisa ukuba izinto zomatshini zihlala zilungelelaniswe ngokuchanekileyo, ziphepha naziphi na iingcangcazelo ezibangelwa bubushushu okanye utshintsho olunokuchaphazela ukuchaneka kwe-wafer yokufakela i-wafer. Olu zinzo lunceda ukuqinisekisa umgangatho ohambelanayo kuzo zonke ii-wafers ezicutshungulwayo.

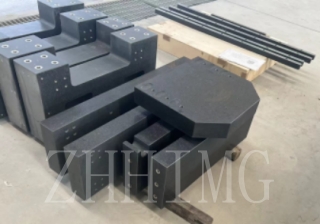

Isiseko Esiqinileyo Nesizinzileyo Sokuchaneka

Ukuqina kwegranite yenye into ebalulekileyo ekunciphiseni ukungcangcazela. Ulwakhiwo lwayo oluqinileyo lubonelela ngesiseko esizinzileyo somatshini wokutshixa i-wafer, okuthintela nayiphi na intshukumo okanye ukugoba okungafunekiyo. Ukuchaneka - umphezulu womhlaba wesiseko somatshini wegranite kukwavumela ukufakwa ngokuchanekileyo kwezixhobo zomatshini, okwandisa uzinzo ngakumbi. Xa umatshini ufakwe ngokuqinileyo kwisiseko segranite, unokusebenza ngesantya esiphezulu kunye nokungcangcazela okuncinci, okuvumela amaxesha okucubungula akhawulezileyo ngaphandle kokulahlekelwa ngokuchanekileyo.

Amabali empumelelo ehlabathi okwenyani

Kwiziko eliphambili lokuvelisa ii-semiconductor, ukwamkelwa kweziseko zoomatshini be-granite kwiimashini zokufaka ii-wafer kukhokelele ekuphucukeni okuphawulekayo komgangatho wemveliso. Iipropati zokunciphisa ukungcangcazela kwe-granite zinciphise ukwenzeka kokuqhekeka okuncinci kwii-wafers ezifakwe ii-slot, zandisa izinga lemveliso ukusuka kwi-85% ukuya kwi-93%. Ukongeza, ukuzinza okuphuculweyo kuvumele ukonyuka kwama-20% kwisantya sokusebenza komatshini, nto leyo enyusa imveliso iyonke.

Ukuqukumbela, iziseko zoomatshini begranite zidlala indima ebalulekileyo ekunciphiseni ukungcangcazela kwiimashini zokufaka iiwafer. Iipropati zazo zokuxinana okuphezulu, ukungcangcazela - ukudambisa, uzinzo lobushushu, kunye nokuqina ziyadibana ukudala imeko yokusebenza ezinzileyo nechanekileyo. Kubavelisi be-semiconductor abajonge ukuphucula umgangatho kunye nokusebenza kakuhle kokucubungula iiwafer zabo, ukutyala imali kwiziseko zoomatshini begranite sisisombululo esiqinisekisiweyo nesisebenzayo.

Ixesha leposi: Juni-12-2025