Iimfuno zemetrology yanamhlanje kunye nokuveliswa okukhulu kudla ngokufuna iqonga legranite elikhulu kakhulu kunalo naliphi na ibhloko enye enokubonelelwa yi-quarry. Oku kukhokelela kwenye yezona ngxaki zinzima kubunjineli obuchanekileyo kakhulu: ukudala iqonga legranite elidibeneyo okanye elidibeneyo elisebenza ngokuzinza kwe-monolithic kunye nokuchaneka kwenqanaba le-micron yento enye.

Kwi-ZHONGHUI Group (ZHHIMG®), ukusombulula le ngxaki akupheleli nje ekudibaniseni iziqwenga; kukwamalunga nokwenza ijoyinti ingabonakali ngokwemetrologically.

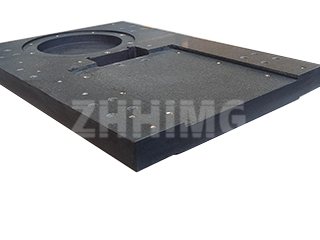

Ngaphaya kwemida yeBloko enye

Xa kusenziwa isiseko seeCoordinate Measuring Machines ezinkulu (iiCMM), izixhobo zokuhlola i-aerospace, okanye iinkqubo ze-gantry ezikhawulezayo ezenziwe ngokwezifiso, imida yobukhulu ifuna ukuba sidibanise amacandelo amaninzi e-granite. Ukuqinisekisa ukuthembeka kweqonga, ingqwalasela yethu itshintshela kwiindawo ezimbini ezibalulekileyo: Ukulungiswa koMphezulu ngocoselelo kunye noHlalutyo oluDibeneyo lwendibano yonke.

Inkqubo iqala ngokulungiselela imiphetho yegranite eza kudibana kwi-splice. Ezi ndawo azisitheli nje emhlabeni; zixhonywe ngesandla ukuze kufezekiswe ukuthe tye okugqwesileyo kunye nomphezulu woqhagamshelwano ongenasiphako. Olu lungiselelo lunzima luqinisekisa unxibelelwano olusondeleyo nolugqibeleleyo, olungenazikhewu phakathi kwamacandelo, kunye naluphi na uphambuko olulinganiswa ngamaqhezu e-micron—ukunyamezelana okuqinileyo kakhulu kunobuthebelele obufunekayo beqonga.

I-Epoxy yoLwakhiwo: Isibopho esingabonakaliyo soBuchule

Ukukhetha indlela yokudibanisa kubaluleke kakhulu. Izibophelelo zemveli zoomatshini, ezifana neebholiti, zizisa uxinzelelo lwendawo, nto leyo ebeka emngciphekweni ukuzinza kwendalo kwegranite kunye neempawu zayo zokuthomalalisa ukungcangcazela.

Kwindibano esisigxina nechanekileyo, umgangatho weshishini kunye nendlela esiyithandayo yiStructural Epoxy Bonding esebenza kakhulu. Le resin ikhethekileyo isebenza njengomaleko oncamathelayo obhityileyo noqinileyo onika ukuqina okukhulu kwesakhiwo. Okubaluleke kakhulu, i-epoxy isasaza uxinzelelo ngokulinganayo kulo lonke ubude kunye nobunzulu bomdibaniso wejoyinti. Olu qhagamshelo olungenamthungo lunceda iqonga elikhulu ukuba lisebenze njengobunzima obunye, obuqhubekayo, obufanayo, obuthintela ukuphazamiseka kwendawo okunokutshintsha idatha yokulinganisa. Isiphumo seseti esisigxina, engatshintshiyo evala ulungelelwaniso oluchanekileyo olufunyenwe ngexesha lokuhlanganiswa.

Uvavanyo lokugqibela: Ukuqinisekisa ukuchaneka kuMphezulu Omkhulu

Ukuchaneka kokwenyani kwejoyinti ekugqibeleni kuqinisekiswa ngexesha lokulinganisa kokugqibela, kwindawo. Nje ukuba iziqwenga zidityaniswe kakuhle kwaye indibano ibekwe kwisiseko sayo sokuxhasa esenziwe ngokwezifiso nesiqinileyo, wonke umphezulu uphathwa njengento enye.

Iinjineli zethu ezingoochwephesha zisebenzisa izixhobo zokukhanya eziphambili, kuquka amanqanaba e-elektroniki kunye nee-laser interferometers, ukwenza ukugoba kokugqibela kunye nohlengahlengiso. Zilinganisa lonke iqonga, zenze uhlengahlengiso oluncinci kwaye zigoba ngokukhetha kumgca odibeneyo de kufikelelwe kwi-flatness efunekayo kunye ne-Repeat Reading specifications (ngokuqhelekileyo ngokwemigangatho engqongqo ye-ASME B89.3.7 okanye i-DIN 876). Ukuqhubeka komphezulu kwi-splice kuqinisekiswa ngokuqinisekileyo ngezixhobo zokulinganisa ezinobuthathaka ezihamba ngqo phezu kwejoyinti, okuqinisekisa ukuba akukho nyathelo okanye ukungaqhubeki okubonakalayo.

Kwiinkqubo zokuvelisa eziphucukileyo, iqonga legranite elingenamthungo nelidibeneyo alikho ngxaki—liyimfuneko yobunjineli eqinisekisiweyo nenokuthenjwa. Siyakumema ukuba unxibelelane nathi ukuze sixoxe ngendlela esinokuyila ngayo ngokwezifiso size sihlanganise isiseko esihlangabezana neemfuno zakho zemetrology enkulu ngokuchanekileyo okungenakuthelekiswa nanto.

Ixesha leposi: Oktobha-17-2025