Izixhobo ze-CNC zisetyenziswa kakhulu kushishino lwanamhlanje, kwaye ukusebenzisa inkxaso ezinzileyo nehlala ixesha elide efana nebhedi yegranite kudla ngokuba lolona khetho lukhethwayo lokulungisa ngokuchanekileyo. Nangona kunjalo, ukwandiswa kobushushu kunokubangela iingxaki ngokuchanekileyo xa usebenzisa ibhedi yegranite kwizixhobo ze-CNC, ingakumbi kwiindawo ezinobushushu obuphezulu. Eli nqaku lijolise ekuboneleleni ngeengcebiso eziluncedo malunga nendlela yokuphepha iingxaki ngokuchanekileyo ezibangelwa kukwandiswa kobushushu xa usebenzisa ibhedi yegranite kwizixhobo ze-CNC.

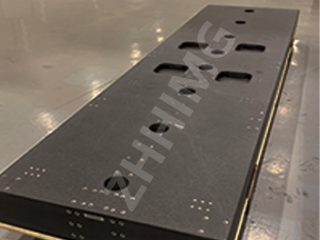

Okokuqala, kubalulekile ukukhetha izinto zegranite ezikumgangatho ophezulu ezine-coefficient yokwandisa ubushushu obuphantsi. I-coefficient yokwandisa ubushushu yegranite iyahluka ngokuxhomekeke kuhlobo kunye nemvelaphi yezinto, kwaye inempembelelo enkulu ekuchanekeni komatshini we-CNC. Ke ngoko, kuyacetyiswa ukuba ukhethe igranite ene-coefficient yokwandisa ubushushu obuphantsi, njengegranite emnyama evela eTshayina okanye eIndiya, ene-coefficient yokwandisa ubushushu emalunga ne-4.5 x 10^-6 / K.

Okwesibini, kubalulekile ukulawula ubushushu bendawo esebenza kuyo izixhobo ze-CNC. Ubushushu begumbi apho kubekwa khona ibhedi yegranite kufuneka buzinze kwaye buhambelane. Naluphi na utshintsho olukhawulezileyo kubushushu lunokubangela ukwanda kobushushu okanye ukuncitshiswa, okukhokelela kwiimpazamo ekuchanekeni komatshini. Ke ngoko, kuyacetyiswa ukuba kuxhotyiswe izixhobo ze-CNC ngenkqubo yolawulo lobushushu enokugcina ubushushu begumbi bukwinqanaba elifanayo.

Okwesithathu, kubalulekile ukukhetha indlela efanelekileyo yokuthambisa ibhedi yegranite. Njengoko ubushushu butshintsha, i-viscosity yegrisi esetyenziswa kwibhedi yegranite nayo iya kutshintsha, ichaphazele ukusebenza kwezixhobo ze-CNC. Ke ngoko, kucetyiswa ukuba kusetyenziswe igrisi ezinzileyo kumaqondo obushushu ahlukeneyo kwaye inokunciphisa impembelelo yokwanda kobushushu kwibhedi yegranite.

Okokugqibela, kubalulekile ukuhlola nokugcina ibhedi yegranite rhoqo ukuqinisekisa uzinzo kunye nokuchaneka kwayo. Nakuphi na ukungalungi okanye iziphene kwibhedi yegranite kunokubangela iingxaki zokuchaneka kwi-CNC machining. Ke ngoko, kuyacetyiswa ukuba kwenziwe uhlolo rhoqo kunye nokugcinwa kwebhedi yegranite ukuze kuchongwe kwaye kulungiswe naziphi na iingxaki ngaphambi kokuba zichaphazele ukuchaneka kwemishini.

Ukuqukumbela, ukusetyenziswa kwebhedi yegranite kwizixhobo ze-CNC kunokubonelela ngozinzo olugqwesileyo kunye nokuchaneka koomatshini bokuchwetheza. Nangona kunjalo, impembelelo yokwandiswa kobushushu kwibhedi yegranite inokubangela iingxaki zokuchaneka, okuchaphazela umgangatho woomatshini bokuchwetheza be-CNC. Ke ngoko, kubalulekile ukukhetha igranite ekumgangatho ophezulu ene-coefficient yokwandiswa kobushushu obuphantsi, ukulawula ubushushu bendawo, ukukhetha indlela yokuthambisa efanelekileyo, kunye nokuhlola rhoqo nokugcina ibhedi yegranite ukuze kuthintelwe iingxaki zokuchaneka ezibangelwa kukwandiswa kobushushu.

Ixesha leposi: Matshi-29-2024