Iispindle zegranite kunye neetafile zokusebenza zizinto ezibalulekileyo ekuvelisweni kwezixhobo zoomatshini ezichanekileyo, izixhobo zokulinganisa, kunye nezinye izixhobo zoshishino. Zidlala indima ebalulekileyo ekuqinisekiseni ukuchaneka nokuzinza kwezi matshini, nto leyo ibalulekileyo ekuhlangabezaneni neemfuno ezichanekileyo zamashishini anamhlanje. Nangona kunjalo, ukuchaneka nokuzinza kweespindle zegranite kunye neetafile zokusebenza kunokuchaphazeleka zizinto ezahlukeneyo, kubandakanya iziphene zokwenza, iimpawu zezinto, kunye neemeko zokusingqongileyo. Ke ngoko, kubalulekile ukuthatha amanyathelo afanelekileyo ukuqinisekisa umgangatho kunye nokuthembeka kwazo.

Enye indlela esebenzayo yokuqinisekisa ukuchaneka nokuzinza kwee-granite spindles kunye nee-worktables kukusebenzisa umatshini wokulinganisa olungelelanisiweyo (i-CMM) ukuze kuhlolwe kwaye kuqinisekiswe. I-CMM sisixhobo sokulinganisa esichanekileyo nesinokubonelela ngokulinganisa okuchanekileyo nokuthembekileyo kwezinto ezintsonkothileyo ezinemilinganiselo emithathu kunye nokuchaneka kwinqanaba elingaphantsi kwe-micron. Ngokusebenzisa i-CMM ukulinganisa nokuqinisekisa ubungakanani, ukunyamezelana, kunye neempawu zejometri zee-granite spindles kunye nee-worktables, abavelisi banokubona naziphi na iimpazamo okanye iimpazamo baze bathathe amanyathelo okulungisa.

Xa usebenzisa i-CMM ukulinganisa izinto zegranite, kubalulekile ukuthathela ingqalelo izinto ezininzi ukuqinisekisa iziphumo ezichanekileyo nezithembekileyo. Okokuqala, i-CMM kufuneka ilinganiswe kwaye iqinisekiswe rhoqo ukuqinisekisa ukuchaneka kwayo nokuzinza. Oku kunokufezekiswa ngokwenza ukulinganiswa okulandelekayo kwe-CMM ngokwemigangatho yamazwe ngamazwe, njenge-ISO 10360. Okwesibini, inkqubo yokulinganisa kufuneka icwangciswe ngononophelo kwaye yenziwe ukuze kuthintelwe iimpazamo zokulinganisa nokuqinisekisa ukuphindaphindwa. Oku kuquka ukukhetha amaqhinga okulinganisa afanelekileyo, ukuseta iiprobe zokulinganisa ezifanelekileyo, kunye nokukhetha iifreyimu zereferensi ezichanekileyo kunye neenkqubo zokulungelelanisa.

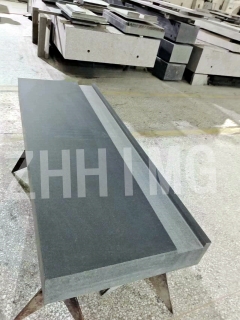

Enye into ebalulekileyo yokuqinisekisa umgangatho wee-spindles ze-granite kunye neetafile zokusebenza kukulawula inkqubo yokuvelisa ngononophelo. Oku kubandakanya ukusebenzisa izinto eziluhlaza ezikumgangatho ophezulu, ezifana nee-granite ezicocekileyo kakhulu ezine-coefficients yokwandisa ubushushu obuphantsi kunye nozinzo oluhle loomatshini, kunye nokusebenzisa iindlela zokuvelisa eziphambili, ezifana nokugaywa ngokuchanekileyo, ukugoba, kunye nokupolisha. Abavelisi kufuneka bathathe amanyathelo okuphepha iziphene zesakhiwo, ezifana nemifantu, imingxuma, kunye nezinto ezibandakanyiweyo, ezinokuchaphazela uzinzo kunye neempawu zoomatshini zezixhobo ze-granite.

Iimeko zendalo zingachaphazela ukuchaneka kunye nokuzinza kwezinto zegranite. Umzekelo, ukuguquguquka kobushushu kunokubangela ukwanda kobushushu okanye ukucutheka kwegranite, okukhokelela kutshintsho lobukhulu kunye nokuguquguquka. Ukunciphisa iziphumo zokungazinzi kobushushu, abavelisi banokuthatha amanyathelo ahlukeneyo, njengokufaka iindawo ezibiyelweyo ezizinzileyo kubushushu, besebenzisa iindlela zokuhlawula ubushushu, kunye nokunciphisa imithombo yobushushu kufutshane nezinto zomatshini wegranite. Ngokufanayo, ukutshintsha komswakama kunokubangela utshintsho lobukhulu ngenxa yokufunxwa komswakama okanye ukufunxwa komswakama. Ukuze kuthintelwe oku, abavelisi banokugcina kwaye basebenzise izinto zegranite kwindawo enomswakama olawulwayo.

Ukuqukumbela, ukuqinisekisa ukuchaneka nokuzinza kwee-spindles ze-granite kunye neetafile zokusebenza kubalulekile ekufezekiseni ukuchaneka okuphezulu kunye nokuthembeka kwiinkqubo zokuvelisa zanamhlanje. Ngokusebenzisa iindlela zokulinganisa nokuhlola eziphambili, ukulawula inkqubo yokuvelisa, kunye nokunciphisa iziphumo zeemeko zokusingqongileyo, abavelisi banokuvelisa izinto ze-granite ezikumgangatho ophezulu ezihlangabezana neemfuno ezingqongqo zoshishino.

Ixesha lokuthumela: Epreli-09-2024