Kwimimandla efana nokuveliswa kwe-semiconductor kunye nezixhobo zokulinganisa ngokuchanekileyo, ukuchaneka kweeplatifomu ezichanekileyo zegranite zichaza ngokuthe ngqo umgangatho wokusebenza kwezixhobo. Ukuqinisekisa ukuba ukuchaneka kweqonga kuhambelana nemigangatho, iinzame kufuneka zenziwe kwiinkalo ezimbini: ukufunyanwa kwezibonakaliso eziphambili kunye nokuthotyelwa kwemimiselo eqhelekileyo.

Ukubonwa kwesalathisi esingundoqo: Ulawulo lwe-multi-dimensional lokuchaneka

Ukubona indawo ethe tyaba: Ukumisela "ukutyiswa" kwenqwelomoya yesalathiso

I-Flatness iyona nto isalathiso esiphambili se-granite echanekileyo yamaqonga, kwaye ngokuqhelekileyo ilinganiswa nge-laser interferometers okanye amanqanaba ombane. I-laser interferometer inokulinganisa ngokuchanekileyo i-undulations yemizuzu kwi-platform surface ngokukhupha i-laser beam kunye nokusebenzisa umgaqo wokuphazamiseka kokukhanya, ngokuchaneka ukufikelela kwinqanaba le-sub-micron. Umgangatho we-elektroniki ulinganisa ngokuhambisa amaxesha amaninzi kwaye uzobe imephu ye-contour ye-three-dimensional ye-platform surface ukujonga ukuba kukho nayiphi na i-protrusions yendawo okanye i-depressions. Ngokomzekelo, iiplatifomu zegranite ezisetyenziswe kumatshini we-photolithography we-semiconductor zifuneka ukuba zibe ne-flatness ye-± 0.5μm / m, oku kuthetha ukuba ukuhlukana kokuphakama ngaphakathi kwe-1-meter ubude akufanele kudlule isiqingatha se-micrometer. Kuphela ngezixhobo zokufumanisa ezichanekileyo ezinokuthi lo mgangatho ungqongqo uqinisekiswe.

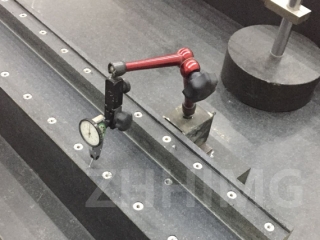

2. Ukubhaqwa kokuthe tye: Qinisekisa "ukuthe tye" kwentshukumo yomgca

Kumaqonga aphethe ngokuchanekileyo iindawo ezihambayo, ukuthe tye kubaluleke kakhulu. Iindlela eziqhelekileyo zokufumanisa yindlela yocingo okanye i-laser collimator. Indlela yocingo ibandakanya ukumisa iingcingo zetsimbi ezichanekileyo kunye nokuthelekisa umsantsa phakathi kwendawo yeqonga kunye neengcingo zetsimbi ukumisela ukuthe tye. I-laser collimator isebenzisa iimpawu ze-laser zokwandisa umgca ukuze ibone impazamo yomgca wendawo yokufakela yomgaqo kaloliwe weqonga. Ukuba ukuchaneka akuhambelani nomgangatho, kuya kubangela ukuba izixhobo zitshintshe ngexesha lokunyakaza, okuchaphazela ukucutshungulwa okanye ukuchaneka komlinganiselo.

3. Ukubona uburhabaxa bomphezulu: Qinisekisa "ukulunga" koqhagamshelwano

Ubunzima bomgangatho weqonga buchaphazela ukulungelelaniswa kofakelo lwamacandelo. Ngokubanzi, imitha yoburhabaxa bosiba okanye imakroskopu yamehlo isetyenziselwa ukubonwa. Isixhobo sohlobo lwe-stylus sirekhoda utshintsho lobude beprofayili ye-microscopic ngokuqhagamshelana nomphezulu weqonga kunye neprobe entle. Iimicroscopes zamehlo zinokujonga ngokuthe ngqo ukuthungwa komphezulu. Kwizicelo ezichanekileyo ezichanekileyo, ubunzima bomgangatho weeplatifomu zegranite kufuneka zilawulwe kwi-Ra≤0.05μm, elilingana nesiphumo esifana nesibuko, ukuqinisekisa ukuba amacandelo achanekileyo afaneleka ngokuqinileyo ngexesha lofakelo kunye nokuphepha ukungcangcazela okanye ukufuduka okubangelwa yizikhewu.

Imigangatho echanekileyo ilandela: imimiselo yamazwe ngamazwe kunye nolawulo lwangaphakathi lweshishini

Okwangoku, kumazwe ngamazwe, imigangatho ye-ISO 25178 kunye ne-GB / T 24632 isetyenziswa ngokuqhelekileyo njengesiseko sokugqiba ukuchaneka kweeplatifomu zegranite, kwaye kukho ukuhlelwa okucacileyo kwezalathi ezifana ne-flatness kunye nokuthe tye. Ukongeza, amashishini emveliso akumgangatho ophezulu ahlala ebeka imigangatho engqongqo yolawulo lwangaphakathi. Ngokomzekelo, imfuno ye-flatness yeqonga legranite lomatshini we-photolithography yi-30% ephezulu kunomgangatho wamazwe ngamazwe. Xa uqhuba iimvavanyo, idatha elinganisiweyo kufuneka ifaniswe nemigangatho ehambelanayo. Iiplatifti ezihambelana ngokupheleleyo nemigangatho zinokuqinisekisa ukusebenza okuzinzile kwizixhobo ezichanekileyo.

Ukuhlola ukuchaneka kwamaqonga achanekileyo egranite yiprojekthi ecwangcisiweyo. Kuphela ngokuvavanya ngokungqongqo izikhombisi ezingundoqo ezinjengokucaba, ukuthe tye, kunye noburhabaxa bomphezulu, kunye nokubambelela kwimigangatho yamazwe ngamazwe kunye nezoshishino, unokuqinisekiswa ukuchaneka okuphezulu kunye nokuthembeka kweqonga, ukubeka isiseko esiluqilima semimandla yokuvelisa ephezulu efana ne-semiconductors kunye nezixhobo ezichanekileyo.

Ixesha lokuposa: May-21-2025