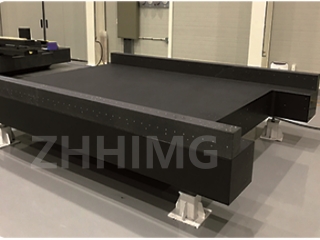

I-precision granite isetyenziswa kakhulu kumashishini ahlukeneyo afana nobunjineli boomatshini, i-metrology, kunye namashishini e-optical. Le nto yaziwa ngokuzinza kwayo okugqwesileyo, ukuqina kwayo, kunye nokuchaneka kwayo. Nangona kunjalo, ngokuhamba kwexesha, i-precision granite ingonakala ngenxa yokuguguleka, iimpembelelo ezingalindelekanga, okanye ukuvezwa kubushushu obugqithisileyo. Oku kunokuphazamisa ukuchaneka kwayo kwaye kuchaphazele inkangeleko yayo.

Ukuba ujongene nale ngxaki, ungakhathazeki. Kweli nqaku, siza kukukhokela kumanyathelo okulungisa inkangeleko yegranite echanekileyo eyonakeleyo, kunye nokulungisa kwakhona ukuchaneka kwayo. Kubalulekile ukuqaphela ukuba la manyathelo kufuneka enziwe yingcali enobuchule enezixhobo nezixhobo ezifanelekileyo.

Ukulungisa imbonakalo yePrecision Granite eyonakeleyo:

Inyathelo 1: Ukucoca Umphezulu: Inyathelo lokuqala lokulungisa inkangeleko yegranite echanekileyo kukucoca umphezulu. Sebenzisa ilaphu elithambileyo kunye nesicoci esingagugiyo ukususa naluphi na uthuli, uthuli, okanye inkunkuma. Ukuba umphezulu unamafutha, sebenzisa i-degreaser uze uhlambe ngamanzi.

Inyathelo lesi-2: Ukuhlola umphezulu: Hlola umphezulu ukuze ubone ubungakanani kunye nohlobo lomonakalo. Ezinye iintlobo zomonakalo zingalungiswa ngokupholisha okulula, ngelixa ezinye zifuna iindlela eziphucukileyo.

Inyathelo lesi-3: Ukupolisha Umphezulu: Imikrwelo emincinci ingapolisha kusetyenziswa i-polish compound kunye nelaphu elithambileyo. Qinisekisa ukuba usebenzisa i-compound efanelekileyo kwiindawo ze-granite ezichanekileyo. I-polish compound kufuneka ifakwe ngendlela ejikelezayo kwaye isulwe ngelaphu elicocekileyo.

Kwimikrwelo enzulu, kungasetyenziswa iphedi yokupolisha yedayimani. Iphedi mayiqhotyoshelwe kwi-variable speed polisher kwaye isetyenziswe ngesantya esicothayo ukuze kuthintelwe ukonakalisa umphezulu ngakumbi. Iphedi mayishukunyiswe ngendlela ejikelezayo, kusetyenziswa amanzi njengesithambisi.

Inyathelo lesi-4: Ukuzalisa iiCrack kunye neeChips: Ukuba kukho iiCrack okanye iiChips kumphezulu, mazizaliswe kusetyenziswa i-epoxy resin. I-resin kufuneka ixutywe ngokwemiyalelo yomenzi kwaye isetyenziswe kwindawo eyonakeleyo. Emva kokuba i-resin iqinile, ingacocwa ukuya kufikelela kwinqanaba lomphezulu ojikelezileyo.

Ukulinganisa kwakhona ukuchaneka kwePrecision Granite:

Inyathelo 1: Ukujonga Ukuchaneka: Ngaphambi kokuba ulungise kwakhona i-precision granite, kubalulekile ukujonga ukuchaneka kwayo kwangoku. Oku kungenziwa kusetyenziswa isixhobo sokuchaneka esifana ne-laser interferometer okanye iibhloko ze-gauge.

Inyathelo lesi-2: Ukuchonga Ingxaki: Ukuba ukuchaneka kufunyenwe kungekho ngqiqweni, inyathelo elilandelayo kukuchonga ingxaki. Oku kunokubandakanya ukuhlola umphezulu ukuba wonakaliswe na, ukujonga ukulungelelana komatshini, okanye ukujonga ukuchaneka kwezixhobo zokulinganisa.

Inyathelo lesi-3: Ukulungisa Umphezulu: Ukuba umphezulu wegranite echanekileyo ufunyaniswe ungalingani, ungalungiswa kusetyenziswa inkqubo eyaziwa ngokuba yi-lapping. Ukulepha kubandakanya ukukhuhla umphezulu wegranite ngesikrweqe esincinci ukususa amabala aphezulu nokwenza umphezulu othe tyaba.

Inyathelo lesi-4: Ukujonga Ulungelelwaniso: Ukuba ingxaki ifunyenwe ikwindlela umatshini olungelelaniswe ngayo, kufuneka ilungiswe ukuqinisekisa ukuba ihambelana nomphezulu wegranite echanekileyo. Oku kungenziwa kusetyenziswa ii-precision shims okanye izikrufu zokulungisa.

Inyathelo lesi-5: Ukulinganisa kwakhona izixhobo: Nje ukuba i-granite echanekileyo ilungisiwe kwaye ichanekile, kubalulekile ukulinganisa kwakhona izixhobo zokulinganisa ezisetyenzisiweyo nayo. Oku kunokubandakanya ukulungisa inqaku elingu-zero, ukulinganisa izikali, okanye ukutshintsha izinto ezigugileyo.

Ukuqukumbela, i-precision granite yinto exabisekileyo efuna ukulungiswa ngononophelo ukuqinisekisa ukuchaneka kwayo nokuqina kwayo. Ngokulandela amanyathelo achaziweyo kweli nqaku, ungayilungisa imbonakalo ye-precision granite eyonakeleyo kwaye ulungise ukuchaneka kwayo ukuqinisekisa ukuba ihlala isisixhobo esithembekileyo kushishino lwakho.

Ixesha lokuthumela: Okthobha-09-2023