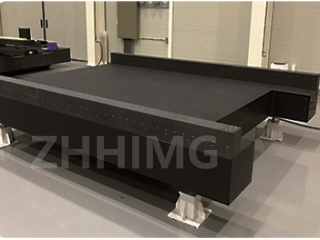

Iziseko zoomatshini begranite ziyinxalenye ebalulekileyo kwiimveliso ezininzi zeTekhnoloji yokuZenzekelayo. Zibonelela ngesiseko esizinzileyo nesiqinileyo sokuba oomatshini basebenze kuso kwaye ziqinisekisa ukuchaneka nokusebenza kakuhle. Nangona kunjalo, njengazo naziphi na ezinye izixhobo, zifuna ukusetyenziswa nokugcinwa ngokufanelekileyo ukuze zisebenze kakuhle kwaye zandise ubomi bazo.

Nazi ezinye iingcebiso malunga nendlela yokusebenzisa nokugcina iziseko zoomatshini begranite kwiimveliso zeTekhnoloji yokuZenzekelayo:

1. Ukufakelwa okufanelekileyo: Qinisekisa ukuba isiseko somatshini sifakwe ngokuchanekileyo. Isiseko kufuneka sibe nomphezulu olinganayo nozinzileyo ukuthintela naluphi na uphazamiseko ngexesha lokusetyenziswa. Kubalulekile ukulandela imiyalelo yomenzi yokufakela nokulinganisa.

2. Ukucoca rhoqo: Ukucoca rhoqo kubalulekile ukugcina ucoceko lwesiseko somatshini wegranite kunye nokuthintela ukuqokelelana kokungcola okanye inkunkuma. Kucetyiswa ukusebenzisa ibrashi ethambileyo okanye ilaphu ukusula amasuntswana omphezulu. Ziphephe iikhemikhali ezinobungozi ezinokukrwela okanye zikrwele umphezulu.

3. Ukuhlolwa rhoqo: Hlola isiseko somatshini rhoqo ukuze ubone naziphi na iimpawu ezibonakalayo zokuguguleka okanye umonakalo, ezinje ngokuqhekeka okanye iitships. Ukuba ufumana nawuphi na umonakalo onjalo, yazisa ingcali efanelekileyo ukuba ilungise isiseko okanye isitshintshe ngesinye esitsha.

4. Jonga ubushushu: Iziseko zomatshini wegranite zinobuthathaka kubushushu obugqithisileyo. Kuphephe ukubeka isiseko kubushushu obugqithisileyo ukuze uthintele ukugqwetheka okanye ukugoba. Gcina ubushushu buhlala buhleli kwindawo ohlala kuyo, kwaye sebenzisa inkqubo yokupholisa ukuba kuyimfuneko.

5. Kuphephe uxinzelelo olugqithisileyo: Ungaze ugcwalise isiseko somatshini ngobunzima okanye uxinzelelo olugqithisileyo. Ukulayisha kakhulu kunokukhokelela kwiintanda, kwiitships, okanye kwenye ingozi. Hlala ulandela imida yomthwalo ecetyiswayo enikwe ngumenzi.

6. Ukuthambisa: Ukuthambisa kuyimfuneko ukugcina isiseko somatshini wegranite sisebenza kakuhle. Jonga iingcebiso zomenzi malunga nokuthambisa okanye uqhagamshelane nengcali yezobuchwepheshe. Qiniseka ukuba ulandela ishedyuli ecetyiswayo yokuthambisa.

7. Ukulinganisa rhoqo: Ukulinganisa kubalulekile ukuqinisekisa ukuba isiseko somatshini kunye nezixhobo zisebenza ngaphakathi kokunyamezelana okufunekayo. Ukulinganisa rhoqo kuya kuqinisekisa ukusebenza ngokuchanekileyo kwaye kwandise ixesha lobomi besiseko somatshini.

Ukuqukumbela, iziseko zomatshini zegranite zizinto ezibalulekileyo kwiimveliso zeTekhnoloji yokuZenzekelayo. Ukusetyenziswa ngokufanelekileyo kunye nokugcinwa rhoqo kwezi ziseko kuya kuqinisekisa ukuba zihlala ixesha elide kwaye zisebenza kakuhle. Landela iingcebiso ezibonelelwe apha ngasentla ukuze ugcine isiseko somatshini kwiimveliso zeTekhnoloji yokuZenzekelayo, kwaye uya kuyonwabela inkonzo egqwesileyo kuzo.

Ixesha leposi: Jan-03-2024