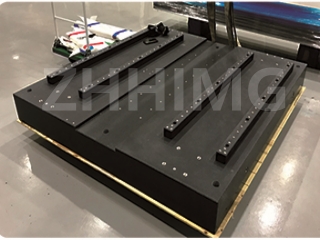

I-Granite yinto ethandwayo kwisiseko soomatshini bokucubungula i-laser ngenxa yokuzinza kwayo okuhle, ukuqina kwayo, kunye nokumelana nokungcangcazela. I-Granite inoxinano oluphezulu kunye ne-porosity ephantsi kunezinye iintsimbi, nto leyo eyenza ukuba ingachaphazeleki kakhulu kukwanda nokuncipha kobushushu, okuqinisekisa ukuchaneka okukhulu kunye nozinzo ngexesha lokucubungula i-laser. Kweli nqaku, siza kuxoxa ngendlela yokusebenzisa isiseko se-granite ekucubunguleni i-laser ngokweenkcukacha.

1. Ukukhetha uhlobo olufanelekileyo lwegranite

Xa ukhetha isiseko segranite sokucubungula nge-laser, kubalulekile ukukhetha uhlobo olufanelekileyo lwegranite oluneempawu ezifanelekileyo zokusetyenziswa okucetywayo. Izinto ekufuneka ziqwalaselwe ziquka:

- Iimbobo - khetha i-granite enembobo ephantsi ukuze uphephe ukungena kweoyile, uthuli kunye nokufuma.

- Ukuqina - khetha uhlobo lwegranite eqinileyo efana neBlack Galaxy okanye iAbsolute Black, enobunzima beMohs obuphakathi kwe-6 kunye ne-7, nto leyo eyenza ukuba ingagugi xa isetyenziswa rhoqo.

- Uzinzo lobushushu - khangela iintlobo zegranite ezine-thermal coefficient ephezulu ezibonelela ngozinzo lobushushu oluhle kakhulu ngexesha lokucubungula nge-laser.

2. Ukuqinisekisa ukuba isiseko segranite silinganisiwe kwaye sizinzile

Izixhobo zokucubungula nge-laser zinobuthathaka kakhulu, kwaye naluphi na utshintsho oluncinci kumphezulu othe tyaba lunokubangela ukungachaneki kwimveliso yokugqibela. Ke ngoko, kubalulekile ukuqinisekisa ukuba isiseko segranite apho izixhobo zifakwe khona sithe tyaba kwaye sizinzile. Oku kunokufezekiswa ngokusebenzisa izixhobo zokulinganisa ngokuchanekileyo ukujonga nokulungisa ulungelelwano lwesiseko uze usilungise endaweni yaso usebenzisa iibholiti okanye i-epoxy.

3. Ukugcina isiseko segranite sicocekile kwaye sinomswakama

Ukugcina ucoceko kunye nokufuma kwesiseko segranite kubalulekile ukuqinisekisa ukuba sihlala ixesha elide kwaye sisebenza kakuhle. Igranite isengozini yokudaya, kwaye nayiphi na intsalela okanye ukungcola okungaphezulu kunokuchaphazela kakubi ukusebenza kwezixhobo zokucubungula nge-laser. Ke ngoko, kubalulekile ukugcina isiseko sicocekile kwaye singenazo inkunkuma ngokulandela iinkqubo zokucoca ezicetyiswayo ngumvelisi.

Ukongeza, i-granite inovelwano kutshintsho lomswakama, kwaye ukuvezwa ixesha elide kumanqanaba aphezulu omswakama kunokubangela ukuba yande. Oku kunokubangela iingxaki zokulungelelaniswa kwezixhobo, okukhokelela kwiingxaki zokuchaneka kwemveliso. Ukuze kuthintelwe ezi ngxaki, kucetyiswa ukuba kugcinwe amanqanaba omswakama malunga ne-50% ngelixa kugcinwa izixhobo kunye nesiseko se-granite.

4. Ukuqinisekisa umoya owaneleyo kwisiseko segranite

Ngexesha lokucubungula nge-laser, izixhobo zivelisa ubushushu obumele bususwe. Ke ngoko, isiseko segranite kufuneka sibe nomoya owaneleyo wokuthintela ubushushu obugqithisileyo. Oku kunokufezekiswa ngokufakelwa kweefeni zomoya okanye imibhobho yomoya eqondisa umoya oshushu kude nesixhobo.

Ukuqukumbela, ukusebenzisa isiseko segranite xa kusetyenzwa nge-laser lukhetho oluhle kakhulu ngenxa yokuqina kwayo okuphezulu, ukuzinza kwayo kunye nokumelana nokungcangcazela. Nangona kunjalo, kubalulekile ukukhetha uhlobo olufanelekileyo lwegranite, ukuqinisekisa ukuba isiseko silinganisiwe kwaye sizinzile, ukugcina amanqanaba okucoceka kunye nokufuma, kunye nokubonelela ngomoya owaneleyo ukuqinisekisa ukusebenza kakuhle. Ngononophelo olufanelekileyo kunye nokugcinwa, isiseko segranite sinokubonelela ngesiseko esizinzileyo nesihlala ixesha elide sezixhobo zokucubungula i-laser iminyaka emininzi ezayo.

Ixesha lokuthumela: Novemba-10-2023