Izixhobo zegranite ziye zathandwa kakhulu kushishino lwe-semiconductor njengoko zibonelela ngeenzuzo ezininzi kunezixhobo zemveli. Iigranite zizixhobo ezifanelekileyo kwizixhobo ze-semiconductor ngenxa yeempawu zazo ezizodwa zomzimba nezekhemikhali. Kweli nqaku, siza kujonga ngokusondeleyo ingcamango yoyilo lwezixhobo zegranite kunye nendlela ezisetyenziswa ngayo kushishino lwe-semiconductor.

I-Granite lilitye elivela ngokwendalo elenziwe ngokuyintloko yi-quartz, i-feldspar, kunye ne-mica. Yaziwa ngoxinano lwayo oluphezulu, ukumelana kakuhle nobushushu, kunye nokuqina okuphezulu. Ezi mpawu ziyenza ibe lilungelo elifanelekileyo kwizixhobo ze-semiconductor. Ngokungafaniyo neentsimbi, ine-coefficient encinci yokwandiswa kobushushu, oko kuthetha ukuba ubukhulu bayo buhlala buhleli nokuba kukho utshintsho kubushushu. Oku kuyenza ibe lilungelo elifanelekileyo kwizixhobo ezichanekileyo apho ukunyamezelana okuqinileyo kubalulekile.

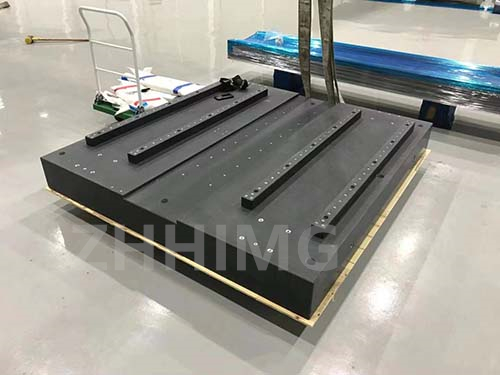

Enye yeenzuzo ezibalulekileyo zezixhobo zegranite kukuqina kwayo okuphezulu, okuphucula ukuchaneka kwezixhobo. Izixhobo zegranite zikhethwa kakhulu kwizixhobo ezichanekileyo ezifana nezixhobo zemetrology kunye nezixhobo zokuhlola umphezulu. Ukuqina kwayo kunciphisa ukungcangcazela, ngaloo ndlela, kunika ukuchaneka okungcono, ukuphindaphindwa, kunye nokuchaneka kwimilinganiselo. Izixhobo zegranite zenze ukuba zifikelele kwinqanaba eliphezulu lokuchaneka kwimilinganiselo, ngaloo ndlela ziphucula umgangatho wezixhobo ze-semiconductor eziveliswayo.

Uzinzo lobushushu lweGranite luyenza ibe yinto efanelekileyo kwizixhobo ezivezwa kumaqondo obushushu aphezulu. Nangona uninzi lwezinto ze-semiconductor zivelisa ubushushu, zifuna amaqondo obushushu aphantsi ukuze zisebenze kakuhle. Izinto zeGranite zinokumelana nokuguquguquka kobushushu ngaphandle kokutshintsha imo okanye ukuphazamisa ukuchaneka kwezixhobo. Ngenxa yoko, izixhobo eziveliswa kusetyenziswa izinto zegranite zihlala zithembekile kwaye ziyafana.

Izixhobo zegranite nazo azikwazi ukumelana nokugqwala, nto leyo ibalulekileyo kwishishini le-semiconductor. Nakuphi na ukugqwala kwezixhobo ze-semiconductor kunokukhokelela ekungcoleni kwezinto ze-semiconductor eziveliswayo. Oku kungcoliswa kunokukhokelela ekuncipheni komgangatho, ukwehla kwemveliso, kunye nokungasebenzi kakuhle kwezixhobo kwi-semiconductors. Izixhobo zegranite zithintela ukugqwala kwaye zigcina ubumsulwa bezixhobo ze-semiconductor ukuze zisebenze ixesha elide kwaye zithembeke ngakumbi.

Izixhobo zegranite nazo zinokumelana nokuguguleka okuphezulu, oko kuthetha ukuba izixhobo ezenziwe ngayo zinokuhlala ixesha elide kwaye zisebenze ngcono, naphantsi kweemeko ezinzima. Ngenxa yokuhlala ixesha elide, iqinisekisa ukusebenza kakuhle kwezixhobo ze-semiconductor, ngaloo ndlela iphucula imveliso kwaye inciphise iindleko zizonke.

Ukuqukumbela, ishishini le-semiconductor likhula ngokukhawuleza kwaye liyatshintsha, kwaye ukusetyenziswa kwezixhobo ze-granite kuye kwafumana imfuno yemarike. Iimpawu zayo ezizodwa zenze ukuba ibe ngumviwa ofanelekileyo kubavelisi be-semiconductor ukuvelisa izixhobo ezisebenza kakuhle kakhulu. Ukusetyenziswa kwezixhobo ze-granite kuphucule umgangatho wemveliso yezixhobo ze-semiconductor kunye nokusebenza okuphuculweyo, ukuqina, kunye nokuchaneka. Ngaphezu koko, ishishini le-semiconductor liye lazuza ekusetyenzisweni okukhulu kwezixhobo ze-granite ngeendleko zokulungisa ezincitshisiweyo, imveliso ephuculweyo, kunye nexesha elincitshisiweyo lokukhokela. Ke ngoko, linyathelo elihle kakhulu kubavelisi be-semiconductor ukwamkela izixhobo ze-granite njengesixhobo esitsha nesisebenzayo esikhethwayo kwizixhobo zabo.

Ixesha leposi: Matshi-20-2024