Iiplatifti ezichanekileyo zegranite, ezinobungqongqo obuphezulu, i-coefficient yokwandisa okuphantsi, ukusebenza kakuhle kokudambisa kunye neempawu zendalo ezichasene nemagneti, zinexabiso lesicelo elingenakutshintshwa kwimveliso ephezulu kunye nemimandla yophando lwezenzululwazi apho ukuchaneka kunye nokuzinza kufunwa kakhulu. Ezi zilandelayo ziimeko zesicelo esingundoqo kunye neenzuzo zobugcisa:

I. Ummandla we-Ultra-precision processing equipment

Izixhobo zokuvelisa iSemiconductor

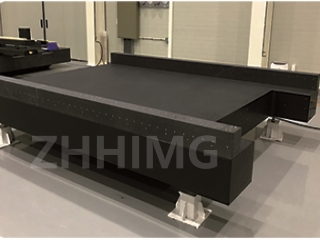

Iimeko zesicelo: Itheyibhile yomatshini weLithography, isiseko somatshini wokudayiza, iqonga lokubeka izixhobo zokupakisha.

Ixabiso lobugcisa:

I-coefficient yokwandiswa kwe-thermal ye-granite kuphela (0.5-1.0) × 10⁻⁶/℃, enokumelana nokuguquguquka kweqondo lokushisa ngexesha lokuvezwa kwe-nanoscale yomatshini we-lithography (impazamo yokufuduka <0.1nm kwindawo ye-± 0.1℃).

Isakhiwo sangaphakathi se-micro-pore senza i-damping yendalo (i-damping ratio 0.05 ukuya kwi-0.1), icinezela i-vibration (i-amplitude <2μm) ngexesha lokusika ngesantya esiphezulu ngomatshini wokudayela kunye nokuqinisekisa ukuba i-edge roughness Ra ye-wafer cutting ingaphantsi kwe-1μm.

2. Ukuchaneka koomatshini bokuSila kunye nokulungelelanisa oomatshini bokulinganisa (CMM)

Imeko yesicelo:

Isiseko somatshini wokulinganisa ulungelelwaniso oluthathu luthatha isakhiwo se-granite esidibeneyo, kunye ne-flatness ye-± 0.5μm / m. Idityaniswe nomzila wesikhokelo esijikelezayo emoyeni, ifezekisa ukuchaneka kwentshukumo ye-nano-level (phinda ukuchaneka kokubeka indawo ± 0.1μm).

I-worktable yomshini wokugaya i-optical ithatha isakhiwo esidibeneyo se-granite kunye nentsimbi yesilivere. Xa kusila iglasi ye-K9, ukukhanya komphezulu kungaphantsi kwe-λ/20 (λ=632.8nm), kuhlangatyezwana neemfuno zokusetyenzwa kwe-ultra-smooth zelensi zelaser.

Ii. Ummandla we-Optics kunye neeFotonikhi

Iiteleskopu zeenkwenkwezi kunye neenkqubo zelaser

Usetyenziso oluqhelekileyo:

Iqonga lenkxaso lomphezulu wokubonisa iteleskopu yerediyo enkulu ithatha ubume be-granite honeycomb, obulula kubunzima bokuzimela (ubunzima obuyi-2.7g/cm³) kwaye inokumelana nokungcangcazela komoya onamandla (deformation < 50μm phantsi komoya womgangatho we-10).

I-platform ye-optical ye-laser interferometer isebenzisa i-micro-porous granite. I-reflector ilungiswe yi-vacuum adsorption, kunye nephutha le-flatness elingaphantsi kwe-5nm, iqinisekisa ukuzinza kwe-ultra-precision optical experiments ezifana nokubonwa kwamaza obunzima.

2. Ukuchaneka kwenkqubo yecandelo le-optical

Iinzuzo zobugcisa:

Ukungena kombane kunye nokuhanjiswa kombane kweqonga legranite lisondele ku-zero, linqanda impembelelo yokuphazamiseka kombane kwiinkqubo ezichanekileyo ezifana ne-ion beam polishing (IBF) kunye ne-magnetorheological polishing (MRF). Ubume bomphezulu buchanekile ixabiso le-PV lelensi ye-asphical esetyenziweyo inokufikelela ku-λ/100.

Iii. I-Aerospace kunye noHlolo oluchanekileyo

Iqonga lokuhlola icandelo lokubhabha

Iimeko zesicelo: Uhlolo oluthathu lwamaphiko eenqwelo-moya, umlinganiselo wemilo kunye nokunyamezelwa kwesikhundla samalungu olwakhiwo lwealluminiyam ye-aviation.

Ukusebenza okungundoqo:

Umphezulu weqonga legranite liphathwa yi-electrolytic corrosion ukwenza iipatheni ezintle (ngoburhabaxa beRa 0.4-0.8μm), ilungele iiprobes zetrigger ezichanekileyo, kwaye impazamo yokufumanisa iprofayili yeblade ingaphantsi kwe-5μm.

Iyakwazi ukumelana nomthwalo ongaphezu kwe-200kg yamacandelo e-aviation, kwaye utshintsho lwe-flatness emva kokusetyenziswa kwexesha elide lungaphantsi kwe-2μm / m, ukuhlangabezana neemfuno zokugcinwa ngokuchanekileyo kweBanga le-10 kushishino lwe-aerospace.

2. Ulungelelwaniso lwamacandelo okukhangela angaphakathi

Iimfuno zobuchwephesha: Ukulinganisa okuzinzileyo kwezixhobo ezinertial ezifana negyroscopes kunye neaccelerometers kufuna iqonga lereferensi elizinzile kakhulu.

Isisombululo: Iqonga legranite lidityaniswe nenkqubo ye-vibration esebenzayo ye-vibration (i-frequency yendalo <1Hz), ukufikelela kwi-high-precision calibration ye-zero-offset stability of inertial components <0.01 ° / h kwindawo ene-vibration acceleration <1×10⁻⁴g.

Iv. Nanotechnology kunye neBiomedicine

Ukuskena iqonga lemakroskopu (SPM)

Umsebenzi ongundoqo: Njengesiseko se-atomic force microscopy (AFM) kunye ne-scan tunneling microscopy (STM), kufuneka ibe yodwa kwi-vibrations yokusingqongileyo kunye ne-thermal drift.

Iimpawu zokusebenza:

I-platform ye-granite, ngokudibanisa nemilenze yokuhlukanisa i-pneumatic vibration, inokunciphisa izinga lokudluliselwa kwee-vibrations zangaphandle (1-100Hz) ukuya ngaphantsi kwe-5%, ukufezekisa umfanekiso we-atomic-level ye-AFM kwindawo ye-atmospheric (isisombululo <0.1nm).

Uvakalelo lobushushu lungaphantsi kwe-0.05μm/℃, oluhlangabezana neemfuno zokujongwa kwe-nanoscale yeesampulu zebhayoloji kwiqondo lobushushu elingaguqukiyo (37℃±0.1℃) kokusingqongileyo.

2. Izixhobo zokupakisha zeBiochip

Imeko yesicelo: Iqonga eliphezulu lokulungelelaniswa kwe-DNA ye-chips zokulandelelanisa i-chips ithatha iileyili ze-granite ze-air-floating guide, kunye nokuchaneka kwendawo ye-± 0.5μm, iqinisekisa i-sub-micron bonding phakathi kwesiteshi se-microfluidic kunye ne-electrode yokufumanisa.

V. Iimeko zezicelo ezisakhulayo

Isiseko sezixhobo zekhompyutha zeQuantum

Imingeni yobuchwephesha: Ukusetyenziswa kweQubit kufuna amaqondo obushushu aphantsi kakhulu (inqanaba lemK) kunye nemekobume yomatshini ezinzileyo kakhulu.

Isisombululo: Ipropathi ephantsi kakhulu yokwandisa i-thermal ye-granite (izinga lokwandisa <1ppm ukusuka -200℃ ukuya kwiqondo lokushisa kwegumbi) inokuhambelana neempawu ze-contraction ye-ultra-low low temperatures superconducting magnets, ukuqinisekisa ukuchaneka kokulungelelaniswa ngexesha lokupakishwa kwee-chips ze-quantum.

2. Inkqubo ye-Electron Beam Lithography (EBL).

Ukusebenza okungundoqo: Ipropathi yokugquma yeqonga legraniti (ukumelana > 10¹³Ω · m) kuthintela ukusasazeka kwe-electron beam. Idibaniswe ne-electrostatic spindle drive, ifezekisa i-high-precision lithography pattern yokubhala kunye nobubanzi bomgca we-nanoscale (<10nm).

Isishwankathelo

Ukusetyenziswa kwamaqonga achanekileyo egranite kwandisiwe ukusuka koomatshini bokuchaneka bendabuko ukuya kwiindawo ezibukhali ezifana ne-nanotechnology, i-quantum physics, kunye ne-biomedicine. Ukukhuphisana kwayo okungundoqo kulele ekudityaneni okunzulu kweempawu eziphathekayo kunye neemfuno zobunjineli. Kwixesha elizayo, ngokudityaniswa kobuchwepheshe bokuqinisa obuhlanganisiweyo (obufana negraphene-granite nanocomposites) kunye nobuchwepheshe bokuqonda obukrelekrele, iiplatifomu zegranite ziya kutyhoboza kwiindlela zokuchaneka kwenqanaba leathom, uzinzo olugcweleyo lobushushu obugcweleyo, kunye nesiseko sokwenza izinto ezininzi ezisisiseko, ukuxhasa ukuhlanganiswa kokwenziwa kwesiseko esisisiseko.

Ixesha lokuposa: May-28-2025