Kwiindawo ezichanekileyo zokwenziwa kwezinto ngokuchanekileyo—ukusuka kwiimoto nakwi-aerospace ukuya kwi-electronics eziphambili—umda wempazamo awukho. Nangona iiGranite Surface Plates zisebenza njengesiseko sehlabathi jikelele se-metrology jikelele, iGranite Inspection Plate yi-benchmark ekhethekileyo, ezinzileyo kakhulu ezinikele ekuqinisekisweni kwecandelo kunye nokuhlanganiswa okuncedisiweyo. Sisixhobo esibalulekileyo esisetyenziselwa ukuqinisekisa i-geometry yangaphandle, ukuphambuka kobukhulu, kunye nokuthamba kweendawo ezinexabiso eliphezulu, ukuqinisekisa ukuba ziyahlangabezana neemfuno ezingqongqo zobunjineli banamhlanje.

Umgaqo weDatum eQinisekileyo kakhulu

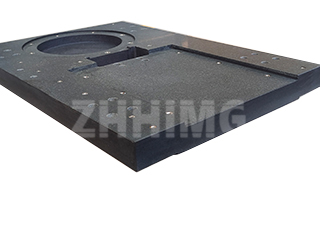

Umsebenzi ophambili weGranite Inspection Plate uxhomekeke ekuzinzeni kwayo okuphezulu kunye nomgaqo "womphezulu we-datum ozinzileyo kakhulu."

Umphezulu osebenzayo uphantsi kwenkqubo yokulapha echanekileyo kakhulu, nto leyo efikelela kuburhabaxa bomphezulu obuphantsi kakhulu (ngesiqhelo iRa ≤ 0.025 μm) kunye nokuchaneka kokuthe tyaba ukuya kuthi ga kwiGrade 0 (≤ 3 μm/1000 mm). Oku kubonelela ngeplani yesalathiso engaguqukiyo, engaguqukiyo.

Ngexesha lokuhlolwa, izinto zibekwa kulo mphezulu. Izixhobo ezifana nezikhombisi zedayile okanye iigeyiji ze-lever zisetyenziselwa ukulinganisa umsantsa wemizuzu phakathi kwento kunye nepleyiti. Le nkqubo ivumela iinjineli ukuba ziqinisekise ngoko nangoko ukuba i-flat kunye ne-parallelism yento, okanye zisebenzise ipleyiti njenge-datum ezinzileyo ukujonga iiparameter ezibalulekileyo ezifana nesithuba semingxuma kunye nokuphakama kwesinyathelo. Okubaluleke kakhulu, ukuqina okuphezulu kwegranite (i-Elastic Modulus ye-80-90 GPa) iqinisekisa ukuba ipleyiti ngokwayo ayiphambuki okanye ayiguquki phantsi kobunzima bezinto ezinzima, okuqinisekisa ukuthembeka kwedatha yokuhlolwa.

Ubunjineli boHlolo: Uyilo kunye nokuBalasela kwezinto eziphathekayo

IiPlati zoHlolo zeZHHIMG® zenzelwe ukugxila ekuhlengahlengiseni uhlolo kunye neenkcukacha ezicokisekileyo:

- Ukuziqhelanisa Ngokwezifiso: Ngaphaya komphezulu othe tyaba ongaphakathi, iimodeli ezininzi zinemingxuma edibeneyo okanye ii-V-grooves. Ezi zibalulekile ekulungiseni ngokukhuselekileyo iindawo ezintsonkothileyo okanye ezingalinganiyo, ezifana nee-shafts kunye nezinto ezimile njengediski, ukuthintela intshukumo ngexesha lokulinganisa okubuthathaka.

- Ukhuseleko kunye nokuSebenza: Imiphetho igqityezelwa nge-chamfer ethambileyo nengqukuva ukuphucula ukhuseleko lomqhubi kunye nokuthintela ukwenzakala ngengozi.

- Inkqubo Yokulinganisa: Isiseko sepleyiti sixhotyiswe ngeenyawo ezixhasayo ezilungisekayo (ezifana nezikrufu zokulinganisa), ezivumela umsebenzisi ukuba alungise ngokuchanekileyo ipleyiti ukuze ilungelelaniswe ngokugqibeleleyo (≤0.02mm/m ukuchaneka).

- Umgangatho wezinto eziphathekayo: Sisebenzisa i-granite yodidi oluphezulu kuphela, engenamabala kunye neentanda, edlula kwinkqubo yokuguga yendalo enzima yeminyaka emi-2 ukuya kwemi-3. Le nkqubo inde isusa uxinzelelo lwangaphakathi lwezinto eziphathekayo, iqinisekisa uzinzo lwexesha elide kunye nexesha lokugcinwa ngokuchanekileyo elidlula iminyaka emihlanu.

Apho Ukuchaneka Kungenakuxoxiswana Khona: Iindawo Eziphambili Zokusetyenziswa

Ipleyiti yoHlolo lweGranite ayibalulekanga apho ukuchaneka okuphezulu kuchaphazela ngqo ukhuseleko kunye nokusebenza:

- Ishishini leeMoto: Kubalulekile ukuqinisekisa ukuba iibhloko zeenjini kunye neebhokisi zetransmission zithe tyaba ukuqinisekisa ukuthembeka kokutywinwa.

- Icandelo leeNqwelo-moya: Lisetyenziselwa ukuqinisekiswa okubalulekileyo kweebhleyidi zeturbine kunye nezixhobo zokufika, apho ukuphambuka kusongela ukhuseleko lokubhabha.

- Ukwenza iMould kunye neDie: Ukuqinisekisa ukuchaneka komphezulu wemingxunya kunye nee-cores zemould, ukuphucula ngokuthe ngqo umgangatho wesamente yokugqibela okanye imveliso eyenziweyo.

- I-Electronics kunye ne-Semiconductor: Kubalulekile ekuhlolweni kwezixhobo ze-semiconductor ezisebenza ngesantya esiphezulu, apho ukulungelelaniswa kwenqanaba le-micron kuyimfuneko ukuze kusebenze ngokuchanekileyo.

Ukukhusela idatha yakho: Iindlela ezilungileyo zoLondolozo

Ukuze ugcine ukuchaneka kwe-sub-micron yePlate yakho yoHlolo, kufuneka ulandele imigaqo yolondolozo engqongqo:

- Ucoceko Luyimfuneko: Emva nje kokuhlolwa, susa yonke intsalela yezinto (ingakumbi iitships zesinyithi) kumphezulu usebenzisa ibrashi ethambileyo.

- Isilumkiso Sokugqwala: Kuthintelwe ngokungqongqo ukubeka ulwelo olugqwala (ii-asidi okanye ii-alkali) kumphezulu wegranite, njengoko zinokuqhekeza ilitye ngonaphakade.

- Ukuqinisekiswa Okuqhelekileyo: Ukuchaneka kwepleyiti kufuneka kuqinisekiswe rhoqo. Sicebisa ukulinganiswa ngee-flatness gauges eziqinisekisiweyo rhoqo emva kweenyanga ezintandathu.

- Ukuphatha: Xa uhambisa ipleyiti, sebenzisa kuphela izixhobo zokuphakamisa ezikhethekileyo kwaye uphephe ukuthambekisa okanye ukwenza ipleyiti ibe sengozini ngequbuliso, nto leyo enokubeka emngciphekweni ukuzinza kwayo ixesha elide.

Ngokuphatha iGranite Inspection Plate njengesixhobo esichanekileyo, abavelisi banokuqinisekisa amashumi eminyaka okuqinisekiswa okuthembekileyo, okuxhasa umgangatho kunye nokhuseleko lweemveliso zabo ezintsonkothileyo.

Ixesha lokuthumela: Novemba-05-2025