Kubavelisi kunye neengcali zemetro kulo lonke elaseMntla Melika, ukusuka kwiindawo zoshishino zase-United States ukuya kwimigangatho efunekayo yababoneleli begranite surface plate eKhanada, igranite surface plate yeyona nto ibalulekileyo yokulinganisa ubukhulu. Esi sixhobo sisisiseko, nokuba sisebenza njenge-reference plane elula okanye sidityaniswe njengecandelo elibalulekileyo kumatshini ophucukileyo njenge-granite surface plate CNC bed, simele utyalo-mali olukhulu kulawulo lomgangatho. Sekunjalo, ukuqinisekisa olo tyalo-mali kufuna ukuqonda okunzulu ngabaqhubi beendleko, iimfuno zolondolozo, kunye nokuqinisekiswa kokulinganiswa okufanelekileyo.

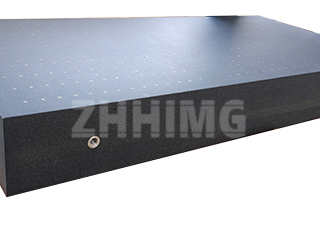

Umbuzo wokuqala othi, “Yimalini ixabiso lepleyiti yomphezulu wegranite?”, uvula ucango lwexabiso elintsonkothileyo. Ixabiso lepleyiti yomphezulu alikho nje ixabiso lezinto eziluhlaza; libonisa umgangatho welitye (ubuninzi, ukuxinana, kunye nokuzinza), ukuchaneka kwenkqubo yokuleqa, kunye nokuqina kwenkqubo yokuqinisekisa. Igranite engabizi kakhulu, enobunzima obuphantsi, edla ngokuchongwa ngombala wayo okhanyayo, inokonga iindleko zepleyiti yomphezulu wegranite, kodwa ngokungathandabuzekiyo ikhokelela kwiindleko eziphezulu zexesha elide ngenxa yokuguga ngokukhawuleza, ukungakwazi ukuzinza kobushushu, kunye nokulungiswa kwakhona rhoqo. Igranite emnyama yeprimiyamu, njengezinto ezisetyenzisiweyo yiZHHIMG® enobunzima obuphantse bube yi-3100 kg/m³, iqinisekisa uzinzo oluphezulu kunye nokugcinwa okungasoloko kwenzeka, okwenza ukuba ibe lukhetho olungabizi kakhulu kumjikelo wobomi bemveliso.

Olu bude bexesha lunxulumene ngqo neendlela ezibalulekileyo zokunyamekela ipleyiti yomphezulu wegranite. Ipleyiti yegranite, nangona ibonakala iqinile, isengozini yezinto ezimbini eziphambili: ukuguguleka okurhabaxa kunye nokutshayiswa kobushushu. Inkqubo yokunyamekela ipleyiti yomphezulu wegranite ebanzi kufuneka ijongane nazo zombini ngendlela ekhawulezileyo.

Inxalenye ebalulekileyo yale nkqubo kukucoca ipleyiti yomphezulu wegranite. Inkqubo ecokisekileyo yokucoca imiphezulu yepleyiti yomphezulu wegranite ayikokususa nje ukungcola okubonakalayo; imalunga nokususa amasuntswana amancinci, arhabaxa—njengothuli olucoliweyo okanye inkunkuma yesinyithi—athi, xa ebambeke phakathi kwento yokusebenza kunye negranite, asebenze njengephepha lesanti, atshabalalise ubucaba obuqinisekisiweyo. Ungaze usebenzise izicoci eziqinileyo okanye izicoci ezineasidi, ezinokushiya amasalela okanye ziqhekeze umphezulu welitye. Endaweni yoko, isisombululo sokucoca ipleyiti yomphezulu wegranite esizinikeleyo, esingena-pH, esidityaniswe nelaphu elikhethekileyo, elingena-lint, kufuneka sisetyenziswe imihla ngemihla ukugcina imeko entle yeplani yesalathiso. Eli nyathelo lesiqhelo alinakuxoxiswana ngalo ukugcina ukuchaneka, ngakumbi kwiipleyiti ezisebenza kwiBanga 00 okanye kwii-laboratory tolerances.

Nangona kunjalo, nokuba kucoceka kakhulu kwaye kukhathalelwa kakhulu akunakuthintela ngokupheleleyo iziphumo ezicothayo neziqokelelweyo zokusetyenziswa kunye notshintsho lokusingqongileyo. Oku kusizisa kwimfuneko yepleyiti yomphezulu wegranite elinganisiweyo ngokwenene. Igama elithi "elinganisiweyo" lidla ngokusetyenziswa gwenxa; kufuneka lithethe ukuqinisekiswa okulandelekayo kokuthe tyaba kwepleyiti iyonke, ukuthe tyaba kwendawo, kunye nokuphindaphindwa kwayo. Amashishini asebenza ngokuchanekileyo, kuquka lawo anikezelwa ngababoneleli bepleyiti yomphezulu wegranite eKhanada, axhomekeke kwizatifikethi zokulinganisa ezilandelekayo ezikhutshwe ziilabhoratri ezivunyiweyo ezisebenzisa i-laser interferometry kunye namanqanaba e-elektroniki.

Ukuzibophelela kwe-ZHHIMG® ekuchanekeni kuqinisekisa ukuba ipleyiti nganye ephuma kwisakhiwo sayo esilawulwa yimozulu esingama-10,000 m²—isakhiwo esakhiwe ngekhonkrithi edampiswe kukungcangcazela kunye nemijelo yokwahlula inyikima—siqinisekiswe ngononophelo. Olu nikezelo lubaluleke kakhulu xa ipleyiti isetyenziswa njengesiseko se-CNC sepleyiti yomphezulu wegranite. Kolu setyenziso, ipleyiti isebenza njengesiseko solwakhiwo lwezikhokelo zomgca kunye neemoto zomatshini. Nasiphi na impazamo yejiyometri kwigranite iguqulelwa ngoko nangoko kwiimpazamo kulawulo lokuhamba lwe-CNC, nto leyo echaphazela ngokuthe ngqo ukuchaneka kwenxalenye yokugqibela eyenziwe ngomatshini. Ngenxa yoko, ixesha lokulinganisa isicelo se-CNC sepleyiti yomphezulu wegranite kufuneka libe rhoqo kwaye liqine kunelo lepleyiti yokuhlola eqhelekileyo.

Ngaphaya kokuba tyaba kunye nomgangatho wezinto ezisetyenzisiweyo, abasebenzisi kufuneka baqwalasele uyilo lwesakhiwo. Ubunjineli obufanelekileyo bepleyiti yomphezulu webhloko yegranite—kuquka uyilo kunye nokubekwa kwezinto zokuphakamisa, iindawo zokuxhasa, kunye nomlinganiselo wobukhulu kunye nobubanzi—kubalulekile ukuthintela ukuphambuka phantsi komthwalo. Olu lwakhiwo lugqibelelo luyinto ephambili eqhuba ixabiso lepleyiti yomphezulu wegranite kwaye luphawu lwabavelisi abakumgangatho wehlabathi abaqondayo ukuba ukuchaneka kwakhiwa ukusuka ekuqaleni ukuya phezulu.

Ngokubeka phambili uxinano lwezinto eziphezulu, ukusebenzisa ukhathalelo olucwangcisiweyo lwe-granite surface plate kunye nokucoca inkqubo ye-granite surface plate, kunye nokuzibophelela kwiinkonzo ze-granite surface plate ezilandelekayo nezilinganisiweyo rhoqo, abasebenzisi baqinisekisa ukuba isiseko sabo se-metrology sihlala siyindawo yokubhekisa engagungqiyo, sinikezela ngokuchaneka okuzinzileyo, kwinqanaba le-nanometer nokuba bazifumana phi ii-plate zabo—nokuba zivela kumthengisi wasekuhlaleni okanye kwinkokeli yehlabathi efana ne-ZHHIMG®.

Ixesha leposi: Novemba-25-2025