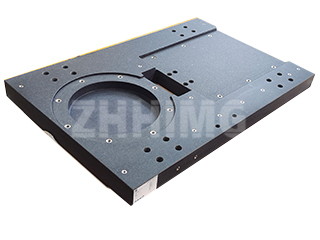

Ibhedi yomatshini isebenza njengesiseko esiphambili saso nasiphi na isixhobo soomatshini, kwaye inkqubo yayo yokuhlanganisa linyathelo elibalulekileyo elilawula ukuqina kwesakhiwo, ukuchaneka kwejometri, kunye nokuzinza kwexesha elide. Kunokuba yindibano elula ebotshelelweyo, ukwakha ibhedi yomatshini ochanekileyo ngumceli mngeni wobunjineli benkqubo enamanqanaba amaninzi. Inyathelo ngalinye—ukususela ekubhekiseleni kokuqala ukuya ekulungisweni kokugqibela kokusebenza—lifuna ulawulo oluhambelanayo lwezinto ezahlukeneyo ukuqinisekisa ukuba ibhedi igcina ukusebenza okuzinzileyo phantsi kwemithwalo yokusebenza enzima.

Isiseko: Isalathiso sokuqala kunye nokulinganisa

Inkqubo yokuhlanganisa iqala ngokuseka iplani yesalathiso esipheleleyo. Oku kudla ngokufezwa kusetyenziswa ipleyiti yomphezulu wegranite echanekileyo kakhulu okanye i-laser tracker njenge-benchmark yehlabathi. Isiseko sebhedi yomatshini siqala silinganiswe kusetyenziswa ii-wedges zokuxhasa (iibhloko ze-chock). Izixhobo zokulinganisa ezikhethekileyo, ezinje ngamanqanaba e-elektroniki, zisetyenziselwa ukulungisa ezi nkxaso de kube kuncitshiswe impazamo yokufana phakathi komphezulu wesikhokelo sebhedi kunye neplani yesalathiso.

Kwiibhedi ezinkulu kakhulu, kusetyenziswa icebo lokulinganisa ngokwezigaba: iindawo zokuxhasa eziphakathi ziyalungiswa kuqala, kwaye ukulinganisa kuqhubekela phambili ukuya eziphelweni. Ukubeka iliso rhoqo kwindlela ethe tye kusetyenziswa isalathisi sokudayela kubalulekile ukuthintela ukugoba phakathi okanye ukugoba emaphethelweni ngenxa yobunzima becandelo. Ingqwalasela ikwanikwa kwizinto ezikwii-wedges zokuxhasa; isinyithi esityhidiweyo sidla ngokukhethwa ngenxa yomlinganiselo waso wokwandisa ubushushu ofanayo nebhedi yomatshini, ngelixa ii-composite pads zisetyenziselwa iimpawu zazo zokudambisa eziphezulu kwizicelo ezinovakalelo lokungcangcazela. Ifilimu encinci ye-anti-seize lubricant ekhethekileyo kwiindawo zoqhagamshelwano inciphisa ukuphazamiseka kokungqubana kwaye ithintela ukutyibilika okuncinci ngexesha lesigaba sokuqina kwexesha elide.

Ukudibanisa ngokuchanekileyo: Ukuhlanganisa iNkqubo yeSikhokelo

Inkqubo yesikhokelo yeyona nto iphambili enoxanduva lokuhamba ngomgca, kwaye ukuchaneka kwayo kokuhlanganiswa kuhambelana ngqo nomgangatho womatshini wezixhobo. Emva kokulungiswa kwangaphambili ngeepini zokufumana, isikhokelo siyabotshwa, kwaye amandla angaphambi koxinzelelo asetyenziswa ngononophelo kusetyenziswa iipleyiti zokucinezela. Inkqubo yangaphambi koxinzelelo kufuneka inamathele kumgaqo "ofanayo noqhubekayo": iibholiti ziqiniswa kancinci ukusuka embindini wesikhokelo ngaphandle, kusetyenziswa i-torque engaphelelanga kuphela kumjikelo ngamnye de kufezekiswe inkcazo yoyilo. Le nkqubo ingqongqo ithintela uxinzelelo lwendawo olunokubangela ukuba isikhokelo sigobe.

Umngeni obalulekileyo kukulungisa indawo yokubaleka phakathi kweebhloko zesilayida kunye nendlela yokuqondisa. Oku kufezekiswa ngendlela yokulinganisa i-feeler gauge edibeneyo kunye nendlela yokulinganisa i-dial indicator. Ngokufaka ii-feeler gauges ezinobukhulu obahlukeneyo kunye nokulinganisa ukufuduka kwe-slider okubangelwayo nge-dial indicator, kwenziwa i-clearance-displacement curve. Le datha ikhokela ukulungiswa okuncinci kwee-eccentric pin okanye ii-wedge blocks kwicala le-slider, ukuqinisekisa ukusasazwa kwe-clearance efanayo. Kwiibhedi ezichanekileyo kakhulu, ifilimu ye-nano-lubrication ingafakwa kumphezulu wendlela yokuqondisa ukunciphisa i-friction coefficient kunye nokuphucula ukuthamba kwentshukumo.

Uqhagamshelo oluqinileyo: I-Spindle Headstock ukuya ebhedini

Unxibelelwano phakathi kwentloko yespindle, intliziyo yokukhupha umbane, kunye nebhedi yomatshini lufuna ulungelelwaniso olucokisekileyo lokudluliselwa komthwalo oqinileyo kunye nokwahlulwa kokungcangcazela. Ukucoceka kweendawo zokudibana kubaluleke kakhulu; iindawo zokunxibelelana kufuneka zisulwe ngononophelo ngesixhobo sokucoca esizinikeleyo ukususa zonke izinto ezingcolisayo, kulandele ukufakwa komaleko omncinci wegrisi ye-silicone ekhethekileyo yohlalutyo ukuphucula ukuqina kokunxibelelana.

Ulandelelwano lokuqinisa ibholithi lubalulekile. Kusetyenziswa ipateni elinganayo, edla ngokuba "yandisa isuka embindini,". Iibholithi ezikwindawo ephakathi ziqiniswa kwangaphambili kuqala, kwaye ulandelelwano luphuma ngaphandle. Ixesha lokukhulula uxinzelelo kufuneka liqwalaselwe emva komjikelo ngamnye wokuqinisa. Kwizibophelelo ezibalulekileyo, isixhobo sokukhangela ibholithi esisebenzisa i-ultrasonic sisetyenziselwa ukujonga amandla e-axial ngexesha langempela, ukuqinisekisa ukusasazwa koxinzelelo olufanayo kuzo zonke iibholithi kunye nokuthintela ukukhululeka kwendawo okunokubangela ukungcangcazela okungafunekiyo.

Emva koqhagamshelo, kwenziwa uhlalutyo lwe-modal. I-exciter ibangela ukungcangcazela kwiifrikhwensi ezithile kwi-headstock, kwaye ii-accelerometers ziqokelela imiqondiso yempendulo kuyo yonke indawo yomatshini. Oku kuqinisekisa ukuba iifrikhwensi ze-resonant zesiseko zihlukaniswe ngokwaneleyo ukusuka kuluhlu lweefrikhwensi zokusebenza kwenkqubo. Ukuba umngcipheko we-resonance ufunyenwe, ukunciphisa kubandakanya ukufaka ii-damping shims kwi-interface okanye ukulungisa i-bolt preload ukuze kuphuculwe indlela yokudlulisa ukungcangcazela.

Ukuqinisekiswa kokugqibela kunye nokuhlawulwa kokuchaneka kwejometri

Nje ukuba idityaniswe, ibhedi yomatshini kufuneka ihlolwe ngokupheleleyo ijiyometri. I-laser interferometer ilinganisa ukuthe tye, isebenzisa iindibano zesibuko ukukhulisa ukuphambuka okuncinci kubude bendlela. Inkqubo ye-elektroniki idwelisa umphezulu, iseka iprofayili ye-3D ukusuka kwiindawo ezininzi zokulinganisa. I-autocollimator ijonga ukulingana ngokuhlalutya ukutshintsha kwendawo yokukhanya eboniswa kwiprism echanekileyo.

Nakuphi na ukuphambuka okufunyenweyo okunganyamezelekiyo kufuna imbuyekezo echanekileyo. Kwiimpazamo zokuthe tye kwindawo ethile kwindlela yokuqondisa, umphezulu we-wedge exhasayo unokulungiswa ngokukrwela ngesandla. Iarhente yomphuhlisi isetyenziswa kwiindawo eziphakamileyo, kwaye ukungqubana okuvela kwisilayida esishukumayo kutyhila ipateni yoqhagamshelwano. Iindawo eziphakamileyo zikrwelwa ngononophelo ukuze kufezekiswe kancinci i-contour yethiyori. Kwiibhedi ezinkulu apho ukukrwela kungenzeki khona, iteknoloji ye-hydraulic compensation ingasetyenziswa. Ii-miniature hydraulic cylinders zifakwe kwii-support wedges, zivumela ukulungiswa okungonakalisiyo kobukhulu be-wedge ngokuguqula uxinzelelo lweoyile, ukufezekisa ukuchaneka ngaphandle kokususwa kwezinto ezibonakalayo.

Ukuthunyelwa kweKhomishini okuKhutshiweyo nokuLayishiweyo

Izigaba zokugqibela ziquka ukuqalisa ukusebenza. Ngexesha lesigaba sokulungisa iimpazamo ezingafakwanga, ibhedi isebenza phantsi kweemeko ezilinganisiweyo ngelixa ikhamera ye-infrared thermal ijonga ubushushu be-headstock kwaye ikhomba iindawo ezishushu ezikufutshane ukuze kubekho ukulungiswa kwetshaneli yokupholisa. Izinzwa zeTorque zijonga ukuguquguquka kokuphuma kwemoto, zivumela ukulungiswa kweendawo zokuvula ityathanga lokuqhuba. Isigaba sokulungisa iimpazamo ezilayishiweyo sinyusa kancinci amandla okusika, sijonga i-vibration spectrum yebhedi kunye nomgangatho wokugqitywa komphezulu oomatshini ukuqinisekisa ukuba ukuqina kwesakhiwo kuhlangabezana neemfuno zoyilo phantsi koxinzelelo lokwenyani.

Ukuhlanganiswa kwecandelo lebhedi yomatshini kukuhlanganiswa okucwangcisiweyo kweenkqubo ezilawulwa ngokuchanekileyo namanyathelo amaninzi. Ngokuthobela ngokungqongqo iiprotokholi zokuhlanganisa, iindlela zokubuyisela amandla eziguquguqukayo, kunye nokuqinisekiswa okucokisekileyo, i-ZHHIMG iqinisekisa ukuba ibhedi yomatshini igcina ukuchaneka kwenqanaba le-micron phantsi kwemithwalo enzima, inika isiseko esingenakushukunyiswa sokusebenza kwezixhobo ezikumgangatho wehlabathi. Njengoko ubuchwepheshe bokufumanisa obukrelekrele kunye nokulungiswa kokuzilungelelanisa buqhubeka buhambela phambili, ukuhlanganiswa kwebhedi yomatshini kwixesha elizayo kuya kuba kuqikelelwa ngakumbi kwaye kuphuculwe ngokuzimela, kutyhala ukwenziwa koomatshini kwiinkqubo ezintsha zokuchaneka.

Ixesha leposi: Novemba-14-2025