Kwihlabathi elikhawulezayo lokwenziwa kwezinto ze-elektroniki, apho ukwenziwa kwezinto zibe lula kwezixhobo kuqhuba ubuchule obungenasiphelo, iteknoloji ye-Surface-mount (SMT) isaqhubeka nokuba yinkqubo ebalulekileyo yokubeka izinto kwiibhodi zesekethe eziprintiweyo (ii-PCB). Izixhobo ze-SMT zanamhlanje—oomatshini bokukhetha nokubeka, iiprinta zesikrini, kunye neenkqubo zokuhlola i-optical optical (AOI)—kufuneka zisebenze ngesantya kunye namanqanaba okuchaneka ahambelana nezinto ezingenakwenzeka. Uzinzo kunye nokuthembeka kwesiseko somatshini azizozinto ezixhasayo kuphela; zizinto ezithintelayo ekugqibeleni kunye nokukhupha. Kwiinkqubo ezininzi zokusebenza okuphezulu, isisombululo esomeleleyo nesingenakushukunyiswa sisekusetyenzisweni kwesiseko somatshini we-granite esikhethekileyo kwitekhnoloji ye-Surface-mount.

Njengoko ubungakanani bezinto buqhubeka buncipha (ukuya kuthi ga kwi-01005 nangaphezulu), kwaye isantya sokubekwa sinyuka, lonke uzinzo oluguquguqukayo lwenkqubo kufuneka luhlolwe kwakhona. Yingakho abavelisi bezixhobo abaphambili bejika kwiipropati zangaphakathi zelitye lendalo ukuze benze isiseko somatshini wegranite wetekhnoloji yeSurface-mount.

Imfuneko yeSiseko seGranite kwi-High-Speed SMT

Kutheni le nto izinto zakudala, zendalo zilukhetho olufanelekileyo lwe-automation ye-SMT yanamhlanje? Impendulo isekelwe kwi-physics esisiseko yokuhamba ngokuchanekileyo. Oomatshini be-SMT abakhawulezayo bavelisa amandla anamandla amakhulu. Ukukhawulezisa ngokukhawuleza kunye nokucotha kweenkqubo ze-gantry, iintloko, kunye nee-conveyors kudala ukungcangcazela okunokuthi, ukuba akulawulwa, kusasazeka kulo lonke ulwakhiwo lomatshini. Oku kushukuma kuthetha ngokuthe ngqo ukungachaneki kokubekwa, iziphene zokunyibilikisa, kunye nokuncipha kokuthembeka kokuhlolwa.

Isisombululo yibhedi yomatshini wegranite kwitekhnoloji yokuxhoma i-Surface. Iimpawu zegranite zenza ukuba ibe yeyona nto ibalaseleyo yokufunxa nokuthomalalisa ezi ziphazamiso zangaphakathi nezangaphandle:

-

Iimpawu zokuDamping eziBalaseleyo: Xa kuthelekiswa nentsimbi okanye i-aluminium, i-granite inomlinganiselo ophezulu kakhulu wokudamping kwangaphakathi. Oku kuthetha ukuba ukungcangcazela koomatshini okubangelwa kukuhamba ngesantya esiphezulu kutshatyalaliswa ngokukhawuleza njengobushushu obuncinci, nto leyo ethintela ukuba kungaphazamisi intloko yokubeka okanye i-optics yokujonga. Eli xesha lokuzinza ngokukhawuleza libalulekile ekuphuculeni ukusebenza ngaphandle kokunciphisa ukuchaneka.

-

I-Thermal Inertia kunye ne-CTE ephantsi: Indawo ye-SMT, ingakumbi kufutshane nee-ovens eziphinda ziphume okanye kwindawo yokusebenza ekufutshane, inokuba notshintsho oluncinci lobushushu. Iintsimbi zisabela ngamandla kolu tshintsho, nto leyo ekhokelela ekwandeni kobushushu kunye nokushukuma kobukhulu. Nangona kunjalo, i-coefficient ephantsi yokwandiswa kobushushu (CTE) yebhedi yegranite yetekhnoloji yokumisa i-Surface iqinisekisa ukuba i-geometry ebalulekileyo yokulungelelanisa umatshini ihlala izinzile kuluhlu lobushushu bokusebenza. Olu zinzo lobushushu lubalulekile ekugcineni ulungelelwaniso olufanelekileyo, ingakumbi kumanyathelo amakhulu oomatshini.

-

Ubunzulu Bokuthe Tye Kwentshukumo Echanekileyo: I-Granite inokutsalwa ize ipholishwe ukuze kufezekiswe ukunyamezelana kobuthe Tye okulinganiswe kwii-sub-microns. Eli nqanaba liphezulu lokuchaneka alinakuxoxiswana ngalo kwiikhokelo zomgca ochanekileyo wokufaka, iibheringi zomoya, kunye neenkqubo zeemoto. Ukuchaneka okuphezulu kobukhulu besiseko se-granite kwitekhnoloji yokukhwelisa i-Surface kuqinisekisa ukuthe tye ngokugqibeleleyo kunye nokulungelelaniswa kwee-axes ezihamba ngokukhawuleza, nto leyo echaza ngokuthe ngqo ukuchaneka kokubekwa kwecandelo.

Ubunjineli kwisizukulwana esilandelayo se-SMT: Izinto kunye nokuhlanganiswa

Indima yegranite kwi-SMT idlulela ngaphaya kwesiseko somatshini omkhulu wegranite. Iqonga le-SMT eliqinileyo lidla ngokusebenzisa izixhobo zegranite ezenziwe ngokwezifiso zobuchwepheshe beSurface-mount ezidityaniswe kwisakhiwo esiphambili. Ezi zixhobo zingabandakanya:

-

Iibhloko zokuFaka ngokuGqibeleleyo: Zisetyenziselwa ukuqinisekisa ukuba iinkqubo zokubona ezibuthathaka kakhulu, izinzwa zokulungelelanisa nge-laser, kunye neekhamera ezithembekileyo zibekwe kwindawo eqinileyo.

-

Imiphezulu yeeBearing zoMoya: Kwiintloko ezikhethwe kakuhle kakhulu, igranite ibonelela ngomphezulu ofanelekileyo, ocwebezelayo kakhulu, ongenamibhobho osebenza ngokugqibeleleyo neebearing zomoya, obonelela ngentshukumo engatshintshiyo nephinda-phindayo.

-

Iipleyiti zezixhobo ezenziwe ngokwezifiso: Izinto ezincinci zegranite ezenzelwe ukubamba nokubhekisa kwiinkqubo ezithile zezixhobo, okuqinisekisa ukulungelelaniswa okuphindaphindiweyo ngokuhamba kwexesha kunye nobushushu.

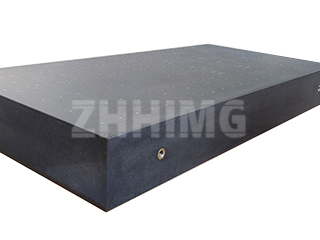

Inkqubo yokuvelisa isiseko somatshini wegranite osebenza kakuhle kwitekhnoloji yeSurface-mount bubungqina bomxube wobugcisa bendabuko kunye nobunjineli obuphambili. Ibandakanya ukukhetha igranite emnyama yendalo ekumgangatho ophezulu, ukuyikhulula kuxinzelelo, uze uyilungise usebenzisa izixhobo ze-CNC zanamhlanje. Iimpawu ezifana nemingxunya ethe tyaba, ii-T-slots, imingxunya eneentloko zokuhambisa intambo, kunye neendawo zokubopha izinto zentsimbi zihlanganiswe ngononophelo kwiinkcukacha ezichanekileyo zomthengi.

Imbuyekezo kutyalo-mali: Ukuchaneka kunye nobude bexesha elide

Ukutyala imali kwisiseko segranite sezixhobo ze-SMT sisigqibo esibalulekileyo esinika imbuyekezo ecacileyo kutyalo-mali. Nangona ixabiso lokuqala lezinto ezisetyenzisiweyo linokuba phezulu kunentsimbi, iingenelo zexesha elide ngokubhekiselele kwimveliso ephezulu, ukuncipha kwezinto ezilahliweyo, kunye nexesha elincinci lokungasebenzi ngenxa yokungahambi kakuhle kwesakhiwo zingaphezulu kakhulu komahluko.

Ibhedi yegranite yetekhnoloji yeSurface-mount inika ireferensi ethembekileyo nehlala ixesha elide eya kugcina ukuthembeka kwayo kangangeenkulungwane, imelana nokuguguleka, ukubola, kunye notshintsho lwangaphakathi kwisakhiwo. Kubavelisi abasebenza kwinqanaba eliphezulu lokuhlanganiswa kwe-elektroniki, apho ukuchaneka kuthetha umahluko phakathi kwemveliso ephumelelayo kunye nokusebenza kwemveliso okungaphumeleli, uzinzo olunikezelwa yisiseko somatshini wegranite esikhethekileyo setekhnoloji yeSurface-mount sisiqinisekiso esiphezulu sokusebenza kunye nokuthembeka. Ukukhetha umatshini onolu siseko kukukhetha ukuhambelana, isantya, kunye nomgangatho ongagungqiyo ekuhlanganisweni kwezixhobo ze-elektroniki ezintsonkothileyo kwihlabathi.

Ixesha leposi: Disemba-01-2025