.

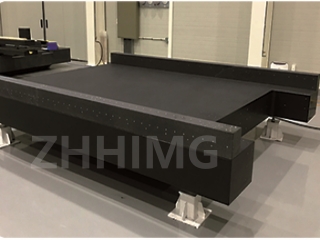

Kwimiba yokucubungula ngokuchanekileyo okuphezulu koomatshini bokuphawula i-laser be-picosecond-level, isiseko, njengecandelo eliphambili elixhasayo lesixhobo, ukukhethwa kwezinto zaso kumisela ngokuthe ngqo ukuzinza kokuchaneka kokucubungula. I-Granite kunye ne-cast iron zizinto ezimbini eziqhelekileyo zokwenza isiseko. Eli nqaku liza kwenza uthelekiso oluvela kwiinkalo ezifana neepropati zomzimba, umgaqo wokunciphisa ngokuchanekileyo, kunye nedatha yesicelo esebenzayo, enika isiseko sesayensi sokuphucula izixhobo.

I. Umahluko kwiPropati yezinto ezibonakalayo: Ingqiqo esisiseko yokusebenza ngokuchanekileyo

I-Granite lilitye lendalo eliyi-igneous, elenziwe yi-crystallization esondeleyo yeeminerali ezifana ne-quartz kunye ne-feldspar ngaphakathi. Ibonakaliswa yisakhiwo esixineneyo kunye nobunzima obuphezulu. Uxinano lwayo luhlala luphakathi kwe-2.7 kunye ne-3.1g/cm³, kwaye i-coefficient yayo yokwandiswa kobushushu iphantsi kakhulu, malunga (4-8) × 10⁻⁶/℃, enokumelana ngempumelelo nempembelelo yotshintsho lobushushu ekuchanekeni kwezixhobo. Ukongeza, isakhiwo esincinci se-granite siyenza isebenze kakuhle ngokudambisa, okwenza ikwazi ukufunxa ngokukhawuleza amandla okungcangcazela angaphandle kwaye inciphise ukuphazamiseka kokungcangcazela ekuchanekeni kokucubungula.

Isinyithi esibunjiweyo, njengesixhobo semveli soshishino, sinobunzima obumalunga ne-7.86g/cm³, amandla aphezulu okuxinzelela, kodwa sishushu.

Inani lokwandiswa (malunga ne-12×10⁻⁶/℃) liphindwe kayi-1.5-3 kunelegranite. Ngaphezu koko, kukho izakhiwo zegrafite eziqhekekileyo ngaphakathi kwesinyithi esityhidiweyo. Ngexesha lokusetyenziswa ixesha elide, ezi zakhiwo zinokukhokelela ekuxinzeleleni koxinzelelo, zichaphazele ukuzinza kwezinto kwaye ekugqibeleni zibangele ukwehla kokuchaneka.

Ii. Indlela yokuNciphisa ngokuGqibeleleyo kwiMishini yePicosecond-level

Ukucubungula nge-laser kwinqanaba lePicosecond kuneemfuneko eziphezulu kakhulu zokuzinza kokusingqongileyo. Nakuphi na ukuguquka okuncinci kwezinto ezisisiseko kuya kwandiswa kwisiphumo sokucubungula. Ukutshintshatshintsha kobushushu, ukungcangcazela okubangelwa kukusebenza kwezixhobo, ukudinwa phantsi komthwalo wexesha elide, njl.njl., zonke zizinto eziphambili ezikhokelela ekunciphiseni ukuchaneka.

Xa ubushushu butshintsha, ubukhulu begranite buyatshintsha kancinci ngenxa yomlinganiselo wayo ophantsi wokwanda kobushushu. Umlinganiselo omkhulu wokwanda kobushushu wesinyithi esityhidiweyo uya kubangela ukuba isiseko siguquke ngendlela ekunzima ukuyibona ngeliso lenyama. Olu tshintsho luya kuchaphazela ngokuthe ngqo ukuzinza kwendlela ye-laser optical kwaye lubangele ukuba indawo yokumakisha itshintshe. Ngokuphathelele ukungcangcazela, uphawu oluphezulu lokudambisa lwegranite lunokunciphisa ukungcangcazela kwe-100Hz kwimizuzwana eyi-0.12, ngelixa isinyithi esityhidiweyo sifuna imizuzwana eyi-0.9. Phantsi kweemeko zokungcangcazela okuphezulu, ukuchaneka kokucubungula izixhobo ezineziseko zesinyithi esityhidiweyo kuthambekele ekuguquguqukeni ngakumbi.

Iii. Uthelekiso lweDatha yokuNciphisa okuNgqo

Ngokweemvavanyo zezikhungo zobungcali, ngexesha lokusebenza kokumakisha i-laser ye-picosecond iiyure ezisi-8 rhoqo, ukuncitshiswa kokuchaneka kokubeka i-XY-axis yezixhobo ezinesiseko segranite kungaphakathi kwe-±0.5μm. Ukuncitshiswa kokuchaneka kwezixhobo zesiseko sesinyithi esityhidiweyo kufikelela kwi-±3μm, ngomahluko omkhulu. Kwimeko-bume elinganisiweyo enotshintsho lobushushu lwe-5℃, impazamo yokuguqulwa kobushushu bezixhobo zesiseko segranite yi-+ 0.8μm kuphela, ngelixa eyezixhobo zesiseko sesinyithi esityhidiweyo iphezulu njenge-+ 12μm.

Ngaphezu koko, ngokwembono yokusetyenziswa kwexesha elide, izinga lokungagwebi kakuhle kweziseko zegranite yi-0.03% kuphela, ngelixa izinga lokungagwebi kakuhle kweziseko zesinyithi eziphosweyo liphezulu njenge-0.5% ngenxa yeengxaki zozinzo lwesakhiwo. Ezi datha zibonisa ngokupheleleyo ukuba phantsi kweemfuno ezichanekileyo zokucubungula kwinqanaba le-picosecond, inzuzo yozinzo lwesiseko segranite ibalulekile.

Iv. Iingcebiso zoPhuculo kunye nezicelo ezisebenzayo

Kumashishini afuna ukuchaneka kokucubungula okugqibeleleyo, ukuphucula isiseko sesinyithi esityhidiweyo ukuya kwisiseko segranite yindlela esebenzayo yokuphucula ukusebenza kwezixhobo. Ngexesha lenkqubo yokuphucula, kufuneka kuqwalaselwe ukuchaneka kokucubungula isiseko segranite ukuqinisekisa ukuba ukuthamba komphezulu kuyahlangabezana neemfuno zoyilo. Kwangaxeshanye, xa zidityaniswe nezixhobo ezincedisayo ezifana nenkqubo yokwahlulahlula ukungcangcazela komoya, ukusebenza kwesixhobo okuchasene nokungcangcazela kunokuphuculwa ngakumbi.

Okwangoku, kumashishini afana nokuveliswa kweetshiphu ze-semiconductor kunye nokulungiswa kwecandelo le-optical precision, oomatshini bokumakisha nge-laser abaneziseko ze-granite baye basetyenziswa kakhulu, nto leyo eyandisa ngempumelelo isivuno semveliso kunye nokusebenza kakuhle kwemveliso. Umzekelo, emva kokuba umenzi othile wecandelo le-optical ephucule izixhobo zesiseko sesinyithi, izinga lokufaneleka kwemveliso linyuke ukusuka kwi-82% ukuya kwi-97%, kwaye ukusebenza kakuhle kwemveliso kwaphucuka kakhulu.

Ukuqukumbela, ekuphuculeni isiseko soomatshini bokumakisha i-laser be-picosecond level, i-granite, enozinzo lwayo olubalaseleyo lobushushu, ukusebenza kwayo okunamandla okudambisa kunye nokukwazi kwayo ukugcina ngokuchanekileyo ixesha elide, iye yaba lukhetho olufanelekileyo kunesinyithi esitshisiweyo. Amashishini anokukhetha ngokufanelekileyo izixhobo ezisisiseko ngokusekelwe kwiimfuno zawo zokucubungula kunye nohlahlo-lwabiwo mali ukuze afezekise uphuculo olupheleleyo lokusebenza kwezixhobo.

Ixesha leposi: Meyi-19-2025