Kwintsimi ye-picosecond-level laser marking machines, ukuchaneka kusona salathisi esiphambili sokuvavanya ukusebenza kwezixhobo. Isiseko, njengomphathi ophambili wenkqubo ye-laser kunye namacandelo achanekileyo, izinto zayo zichaphazela ngokuthe ngqo ukuzinza kokuchaneka kokucubungula. Igranite kunye nentsimbi etyhidiweyo, njengezixhobo ezibini ezisisiseko, zinomohluko omkhulu kwiimpawu ezichanekileyo zokuthomalalisa ngexesha le-picosecond-level ultra-fine processing. Eli nqaku liza kuhlalutya ngokunzulu iingenelo zokusebenza kunye nokungalunganga kwezi zibini ukunika isiseko senzululwazi sokuphucula izixhobo.

Iimpawu zezinto eziphathekayo zigqiba isiseko sokuchaneka

Igranite ngokwesiseko lilitye elivuthayo elenziwe ngenkqubo yejoloji kumakhulu ezigidi zeminyaka. Isakhiwo sayo sangaphakathi se-crystal sixinene kwaye sifana, kunye ne-coefficient yokwandisa i-linear ephantsi njenge-0.5-8 × 10⁻⁶/℃, xa kuthelekiswa ne-alloys echanekileyo efana ne-indium steel. Olu phawu lwenza utshintsho lwe-dimensional luphantse lube yinto engahoywayo xa ubushushu be-ambient buguquguquka, buthintele ngokufanelekileyo i-optical path offset kunye neempazamo zoomatshini ezibangelwa kukwandiswa kwe-thermal kunye nokucutheka. Ukongeza, ingxinano yegranite iphezulu ukuya kutsho kwi-2.6-2.8g/cm³, enesakhono sokufunxa esibalaseleyo. Iyakwazi ukunciphisa ngokukhawuleza ukushukuma kwe-high-frequency vibrations eyenziwa ngexesha lokucubungula i-laser, iqinisekisa ukuzinza kwenkqubo ye-optical kunye neendawo ezihambayo.

Iziseko zentsimbi zisetyenziswa ngokubanzi ngenxa yokusebenza kwazo okugqwesileyo kunye neenzuzo zeendleko. Ulwakhiwo oluqhelekileyo lweflake yegraphite yentsimbi engwevu iyinika umsebenzi othile wokufunxa, onokufunxa malunga ne-30% ukuya kwi-50% yamandla okungcangcazela. Nangona kunjalo, i-coefficient yokwandiswa kwe-thermal yensimbi etyhidiweyo malunga ne-10-12 × 10⁻⁶/℃, eyi-2-3 amaxesha egranite. Ngaphantsi kokuqokelelwa kobushushu obuveliswa yinkqubo eqhubekayo yexesha elide, i-dimensional deformation iyakwazi ukwenzeka. Ngeli xesha, kukho ukuphoswa koxinzelelo ngaphakathi kwentsimbi. Njengoko uxinzelelo lukhutshwa ngexesha lenkqubo yokusetyenziswa, lunokubangela utshintsho olungenakuguqulwa kwi-flatness kunye ne-perpendicularity yesiseko.

Indlela echanekileyo yokunciphisa i-piccosecond-level processing

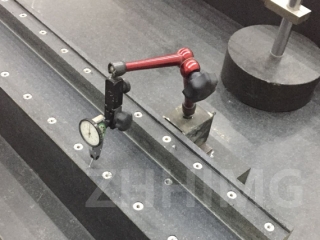

Ukusetyenzwa kwe-laser ye-Picosecond, kunye neempawu zayo ze-ultra-short pulse, inokufikelela ekusebenzeni kakuhle kwinqanaba le-sub-micron okanye nakwinqanaba le-nanometer, kodwa ikwabeka iimfuno ezingqongqo zokuzinza kwesixhobo. Isiseko se-granite, kunye nesakhiwo sayo sangaphakathi esizinzile, sinokulawula impendulo ye-vibration kwinqanaba le-sub-micron phantsi kwempembelelo ye-laser ye-high-frequency, ngokufanelekileyo ukugcina ukuchaneka kokumisa ukugxilwa kwe-laser. Idatha elinganisiweyo ibonisa ukuba umatshini wokumakisha we-laser onesiseko segranite usagcina ukutenxa kobubanzi bomgca ngaphakathi kwe-± 0.5μm emva kokuqhubekeka kwe-8-hour picosecond processing.

Xa isiseko sentsimbi etyhidiweyo sibonakaliswe kwi-high-frequency vibration ye-picosecond laser, isakhiwo sangaphakathi seenkozo siya kuba ne-microscopic fatigue ngenxa yempembelelo eqhubekayo, okubangelwa ukuhla kokuqina kwesiseko. Ukubeka iliso kwidatha evela kwishishini elithile lokuvelisa i-semiconductor libonisa ukuba emva kweenyanga ezintandathu zokusebenza, ukuchaneka kokuchaneka kwesantya sezixhobo ezineziseko zentsimbi etyhidiweyo zifikelela kwi-12%, zibonakaliswa ikakhulu njengokwanda koburhabaxa bemiphetho yemigca kunye nokwandiswa kweempazamo zokubeka. Ngeli xesha, intsimbi etyhidiweyo inovelwano ngokuthelekiswa nokufuma kwendalo. Ukusetyenziswa kwexesha elide kuthanda ukugqwala, ngakumbi ukukhawuleza ukuwohloka kokuchaneka.

Ukuqinisekiswa kweeyantlukwano zokusebenza kwizicelo eziphathekayo

Kwintsimi ye-3C ye-electronic precision component processing, ishishini elaziwayo liqhube uvavanyo lokuthelekisa ekusebenzeni kwezixhobo zeentlobo ezimbini zeziseko zezinto. Kuvavanyo, oomatshini bokumakisha be-laser be-piccosecond abanobume obufanayo baxhotyiswe ngokulandelelanayo nge-granite kunye neziseko zentsimbi zokusika nokumakisha iglasi yezikrini zeselfowuni ezinobubanzi obuyi-0.1mm. Emva kweeyure ezingama-200 zokuqhubekeka kokulungiswa, izinga lokugcinwa kokuchaneka kokulungiswa kwezixhobo zesiseko segranite kwaba ngama-98.7%, ngelixa eso sixhobo sesiseko sentsimbi sasiyi-86.3% kuphela. Imiphetho yeglasi ecutshungulwe ngulo mva yabonisa iziphene ezicacileyo ze-sawtooth.

Ekwenziweni kwamacandelo e-aerospace, idatha yokubeka iliso yexesha elide yeziko elithile lophando ngokucacileyo libonisa iiyantlukwano: Umatshini wokumakisha we-laser onesiseko se-granite une-cumulative precision attenuation engaphantsi kwe-3μm kwiminyaka emihlanu yobomi benkonzo; Nangona kunjalo, emva kweminyaka emithathu, impazamo yokulungiswa kwezixhobo zesiseko sesinyithi esibangelwa ukuguqulwa kwesiseko sigqithise umgangatho wenkqubo ye-± 10μm, kwaye ukulinganisa ukuchaneka komatshini kufuneka kwenziwe.

Iingcebiso zokuphucula izigqibo

Ukuba amashishini athatha ukuchaneka okuphezulu kunye nomjikelo ozinzileyo wokuqhubekeka njengemfuno yawo ephambili, ngakumbi kwimimandla efana neetships ze-semiconductor kunye nezinto ezichanekileyo ze-optical, iziseko zegranite, kunye nokuzinza kwazo okubalaseleyo kwe-thermal kunye nokumelana nokungcangcazela, lukhetho olufanelekileyo lokuphucula. Nangona ixabiso layo lokuqala lokuthengwa kwempahla liyi-30% ukuya kwi-50% ephezulu kuneyentsimbi etyhidiweyo, ngokwembono yeendleko zomjikelo wobomi obupheleleyo, ukuncitshiswa kwamaxesha okulinganisa okuchanekileyo kunye nexesha lokunciphisa izixhobo zolondolozo kunokuphucula kakhulu izibonelelo zizonke. Kwiimeko zesicelo ezineemfuno ezisezantsi zokuchaneka kokusetyenzwa kunye nohlahlo lwabiwo-mali olunyiniweyo, iziseko zentsimbi etyhidiweyo zisenokusetyenziswa njengesisombululo senguqu phantsi kwesiseko sokulawula ngokufanelekileyo imeko-bume yosetyenziso.

Ngokuthelekisa ngokuchanekileyo ukuchaneka kweempawu zokunciphisa i-granite kunye nentsimbi ephonsiweyo kwiprosesa yezinga le-piccosecond, kunokubonwa ukuba ukukhetha isiseko esifanelekileyo kuyisinyathelo esibalulekileyo sokuphucula ukuchaneka kokulungiswa kunye nokuthembeka komatshini wokumakisha laser. Amashishini kufuneka, ngokweemfuno zawo zobuchwepheshe kunye noqwalaselo lweendleko, enze izigqibo zenzululwazi ngesicwangciso sophuculo olusisiseko ukubonelela ngesiseko esiluqilima sesixhobo sokwenziwa kwemveliso ephezulu.

Ixesha lokuposa: May-22-2025