Izixhobo zegranite zisebenza njengomlinganiselo osisiseko wamashishini achanekileyo, kwaye ukusebenza kunye nokugcinwa kwazo kuchaphazela ngokuthe ngqo ukuthembeka kweziphumo zokulinganisa. Kwi-ZHHIMG®, siyaqonda ukubaluleka okubalulekileyo kokukhethwa kwezinto kunye nokunyamekela imihla ngemihla. Siqulunqe isikhokelo sobuchwephesha sokulinganisa kunye nokugcina izixhobo zakho zegranite ukuqinisekisa ukuba izixhobo zakho zihlala zikwimeko efanelekileyo.

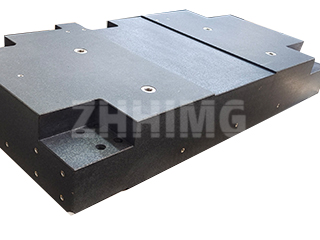

Sikhetha kwaye sisebenzisa i-ZHHIMG® Black Granite yethu ekhethekileyo. Ngenxa yesakhiwo sayo esixineneyo sekristale kunye nobunzima obungaqhelekanga, inamandla okucinezela afikelela kwi-2290-3750 kg/cm² kunye nobunzima be-Mohs obuyi-6-7. Le nto igqwesileyo ayimelani nokuguguleka, i-asidi, kunye ne-alkali, kwaye ayiyi kugqwala. Nokuba umphezulu womsebenzi uchaphazeleke ngengozi okanye ukrwelwe, kuya kubangela ukuxinana okuncinci, kungekhona i-burr ephakanyisiweyo eya kuchaphazela ukuchaneka kokulinganisa.

Ukulungiselela Kwangaphambi Kwesicelo Seenxalenye zeGranite

Ngaphambi kokuba uqale nawuphi na umsebenzi wokulinganisa, ukulungiselela ngokucokisekileyo kubalulekile ukuqinisekisa ukuchaneka:

- Hlola kwaye Ucoce: Qinisekisa ukuba umphezulu wenxalenye yegranite ucocekile kwaye awunamhlwa, umonakalo, okanye imikrwelo. Sebenzisa ilaphu elicocekileyo, elithambileyo okanye ilaphu elingenayo ilinti ukusula kakuhle umphezulu osebenzayo, ususe onke amabala eoyile kunye nenkunkuma.

- Ilungele Umsebenzi: Ngaphambi kokuba ubeke umsebenzi kwinxalenye, qiniseka ukuba umphezulu wawo wokulinganisa ucocekile kwaye awunayo i-burr.

- Lungisa Izixhobo: Lungisa zonke izixhobo kunye nezixhobo kakuhle; kuphephe ukuzibeka ndawonye.

- Khusela Umphezulu: Kwizinto ezithambileyo, ilaphu elithambileyo levelvet okanye ilaphu elithambileyo lokusula linokubekwa kwibhentshi yokusebenzela ukuze likhuseleke.

- Rekhoda kwaye Uqinisekise: Jonga iirekhodi zokulinganisa phambi kokusebenzisa, kwaye ukuba kuyimfuneko, yenza uqinisekiso olukhawulezileyo.

Ukugcinwa Nokucoca Ngokwesiqhelo

Ukugcinwa ngokuchanekileyo nangokungaguquguqukiyo kwemihla ngemihla kubalulekile ukuze kwandiswe ubomi bezinto zakho zegranite.

- Ukucoca Emva Kokusetyenziswa: Emva kokusetyenziswa ngakunye, umphezulu wokusebenza kufuneka ucocwe ngoko nangoko.

- Faka iOyile yoKhuseleko: Emva kokucoca, faka umaleko omncinci weoyile yokukhusela (njengeoyile yomatshini okanye idizili) kumphezulu. Injongo ephambili yale maleko yokukhusela ayikokuthintela umhlwa (njengoko igranite ingagqwali), kodwa kukuthintela uthuli ukuba lunganamatheli, ukuqinisekisa ukuba umphezulu ucocekile ukuze usetyenziswe kwakhona.

- Abasebenzi Abagunyazisiweyo: Nakuphi na ukuqhaqha, uhlengahlengiso, okanye ukuguqulwa kwecandelo kufuneka kwenziwe kuphela ziingcali eziqeqeshiweyo. Izenzo ezingagunyaziswanga azivumelekanga ngokungqongqo.

- Ukuhlolwa rhoqo: Jonga rhoqo ukusebenza kwecandelo kwaye ugcine ingxelo yolondolozo eneenkcukacha.

Iindlela zokulinganisa iGranite Component

Ukulinganisa icandelo legranite linyathelo elibalulekileyo ekusekeni ireferensi echanekileyo. Nazi iindlela ezimbini ezisebenzayo zokulinganisa inqanaba:

- Indlela yeSixhobo esichanekileyo:

- Qala ngokusebenzisa inqanaba lesakhelo, inqanaba le-elektroniki, okanye i-autocollimator ukuze ulinganise inqanaba lokuqala.

- Okulandelayo, sebenzisa inqanaba lebhulorho kunye nenqanaba ukuhlola icandelo lomphezulu ngecandelo. Bala ubucaba ngokusekwe kumlinganiselo uze wenze uhlengahlengiso oluncinci kwiindawo zokuxhasa zecandelo.

- Indlela yoLungiso oluSebenzayo:

- Ngaphambi kokuba ulungise, qiniseka ukuba zonke iindawo zokuxhasa zidibene kakuhle nomhlaba kwaye azixhonywanga.

- Beka umphetho othe ngqo kwi-diagonal yecandelo. Yibethe kancinci isiphelo esinye serula. Indawo efanelekileyo yokuxhasa kufuneka ibekwe malunga nophawu lwe-2/9 kubude berula.

- Landela inkqubo efanayo ukuze ulungise zonke iikona ezine zenxalenye. Ukuba inxalenye ineendawo zokuxhasa ezingaphezulu kwezintathu, sebenzisa indlela efanayo ukuze ulungise iindawo zokuncedisa, uqaphele ukuba uxinzelelo kwezi ndawo kufuneka lube ngaphantsi kancinci kuneekona ezine eziphambili.

- Emva kwale ndlela, uhlolo lokugqibela olusebenzisa inqanaba lesakhelo okanye i-autocollimator luya kubonisa ukuba umphezulu wonke usondele kakhulu kwinqanaba elifanelekileyo.

Ukusebenza Okugqwesileyo Kweenxalenye zeGranite

Izinto zegranite zingcono kuneeplatifomu zesinyithi zemveli ngenxa yeempawu zazo ezibonakalayo ezingenakuthelekiswa nanto:

- Uzinzo Olungaqhelekanga: Lwenziwe kwiminyaka yezigidi zokuguga kwendalo, uxinzelelo lwangaphakathi lwegranite luyasuswa ngokupheleleyo, kwaye ulwakhiwo lwayo lufana. Oku kuqinisekisa ukuba inxalenye ayiguquguquki.

- Ukuqina Okuphezulu: Ukuqina kwayo okugqwesileyo kunye nobunzima, kunye nokumelana kwayo nokuguguleka okunamandla, kuyenza ibe sisiseko esifanelekileyo sokulinganisa ngokuchanekileyo.

- I-Non-Magnetic: Njengento engeyoyesinyithi, ivumela intshukumo egudileyo, engaphazanyiswayo ngexesha lokulinganisa kwaye ayichaphazeleki ngamandla emagnethi.

I-ZHHIMG®, uphawu lokulinganisa kushishino, iqinisekisa ukuba yonke into yegranite ihlangabezana nemigangatho ephezulu yokuchaneka. Zonke iimveliso zethu zikhuselwe ngokupheleleyo ngaphambi kokuba ziphume kumzi-mveliso nasemva kokulungiswa, okuqinisekisa ukusebenza kwazo okuphezulu kwindawo ecocekileyo, engangcangcazeli kakhulu, kwaye enobushushu obuzinzileyo.

Ixesha leposi: Septemba-30-2025