Kwimveliso ephezulu kunye nobunjineli obuchanekileyo, ukusebenza komatshini akuxhomekekanga nje kuphela kwiidrives zawo, ulawulo, okanye isoftware, kodwa ngokusisiseko sisiseko sawo solwakhiwo. Iziseko zezixhobo zomatshini kunye neendibano zesalathiso zichaphazela ngokuthe ngqo ukuchaneka, ukuziphatha kokungcangcazela, ukuzinza kobushushu, kunye nokuthembeka kwexesha elide. Njengoko ukunyamezelana kokuvelisa kuqhubeka nokuqina kumashishini afana ne-aerospace, izixhobo ze-semiconductor, i-optics, kunye ne-automation ephucukileyo, ukukhethwa kwezinto zeziseko zomatshini kuye kwaba sisigqibo sobunjineli esicwangcisiweyo.

Phakathi kwezisombululo ezivavanywa rhoqo ziisiseko zoomatshini be-epoxy granite, iziseko zezixhobo zoomatshini besinyithi esiqhelekileyo, kunye neendibano ze-granite ezichanekileyo zendalo. Ngaxeshanye, iipleyiti zomphezulu we-granite zihlala zizinto ezibalulekileyo zokubhekisa kuzo zombini iimeko zemveliso kunye ne-metrology. Eli nqaku libonelela ngohlalutyo olucwangcisiweyo lwezi zinto kunye namacandelo, lihlola izibonelelo kunye nemida yazo, kwaye lichaza indlela iindibano ze-granite ezichanekileyo ezixhasa ngayo iinkqubo zokuvelisa zanamhlanje. Likwagxininisa indlela i-ZHHIMG enikezela ngayo izisombululo ze-granite ezicwangcisiweyo ezihambelana neemfuno zabathengi bemizi-mveliso yehlabathi.

Isiseko soMatshini we-Epoxy Granite: Iimpawu kunye namatyala okusetyenziswa

I-Epoxy granite, ekwabizwa ngokuba yi-polymer concrete okanye i-mineral casting, yi-izinto ezidityanisiweyoyenziwe ngokubopha ii-mineral aggregates nge-epoxy resin. Ifumene ingqalelo njengesixhobo esisisiseko somatshini ngenxa yeempawu zayo zokudambisa ukungcangcazela kunye nobuchule bokubumba obuguquguqukayo.

Enye yezona nzuzo ziphambili zesiseko somatshini we-epoxy granite kukuxinana kwayo kwangaphakathi okuphezulu. Xa kuthelekiswa nezakhiwo zesinyithi, i-epoxy granite inokunciphisa kakhulu ukudluliselwa kokungcangcazela, iphucule ukugqitywa komphezulu kunye nozinzo oluguquguqukayo kwizicelo ezithile zoomatshini. Ukongeza, iijometri ezintsonkothileyo, iitshaneli zangaphakathi, kunye nezinto ezifakwe ngaphakathi zinokudityaniswa ngexesha lenkqubo yokusika, nto leyo enciphisa iimfuno zoomatshini besibini.

Nangona kunjalo, i-epoxy granite ikwanemida. Uzinzo lwexesha elide luxhomekeke kakhulu kwifom ye-resin, umgangatho wokuphilisa, kunye neemeko zokusingqongileyo. Ukuguga kwe-resin, uvakalelo lobushushu, kunye nemiphumo enokubakho yokuqhekeka kufuneka kuqwalaselwe ngononophelo kwizicelo ezichanekileyo kakhulu okanye ezihlala ixesha elide. Ngenxa yoko, i-epoxy granite idla ngokukhethwa kwizixhobo zoomatshini ezichanekileyo kakhulu kuneenkqubo ezifuna ukuchaneka okukhulu kwiminyaka emininzi yenkonzo.

Isiseko seZixhobo zoMatshini weSinyithi: Isithethe kunye neMiqathango

Isinyithi esitshisiweyo besisoloko sithandwa kakhulu kwiziseko zezixhobo zoomatshini kangangeminyaka engaphezu kwekhulu. Ukuthandwa kwayo kuvela ekusebenzeni kakuhle, ukufunxa okufanelekileyo, kunye neenkqubo zokuvelisa ezisele zimiselwe.Oomatshini be-CNCkwaye izixhobo ezisetyenziswa ngokubanzi ziyaqhubeka nokuxhomekeka kwizakhiwo zesinyithi esityhidiweyo.

Nangona ezi zibonelelo zilungile, izixhobo zomatshini wesinyithi zibonisa iingxaki ezikhoyo kwiindawo ezichanekileyo. Uxinzelelo olushiyekileyo oluvezwa ngexesha lokwenziwa kwesinyithi kunye noomatshini lunokubangela ukuguquguquka kancinci kancinci ngokuhamba kwexesha, nokuba emva konyango lokunciphisa uxinzelelo. Isinyithi sesinyithi sikwanovelwano ngakumbi kulwandiso lobushushu kunye nokuguquguquka kobushushu bendalo, okunokuchaphazela ngokuthe ngqo ukuchaneka kokubekwa.

Ukumelana nokugqwala yenye into ekufuneka iqwalaselwe. Iziseko zentsimbi ephothiweyo zihlala zifuna iingubo zokukhusela kunye neendawo ezilawulwayo ukuthintela i-oxidation, ngakumbi kwiindawo ezifumileyo okanye ezikufuphi negumbi elicocekileyo. Ezi zinto ziye zabangela ukuba abavelisi bezixhobo bavavanye ezinye izixhobo zokusetyenziswa ezifuna uzinzo oluphezulu kunye nokugcinwa okuncinci.

Indibano yeGranite echanekileyo: Inzuzo yoLwakhiwo

Iindibano zegranite ezichanekileyo zimele indlela eyahlukileyo ngokupheleleyo kuyilo lwesakhiwo somatshini. Yenziwe ngegranite yendalo eye yaluphala ngokwendalo kwiminyaka eyizigidi, igranite ayinaxinzelelo kwaye ayitshisi. Olu zinzo lwendalo lubonelela ngenzuzo ebalulekileyo ekugcineni ukuchaneka kwejometri ixesha elide.

Iindibano zegranite ezichanekileyo zenziwa ngeenkqubo zokugaya nokudibanisa ezilawulwayo, zifezekisa ukuba tyaba, ukuthe tye, kunye nokuma nkqo. Ngokungafaniyo nezinto ezibunjiweyo okanye ezidityanisiweyo, igranite ayinangxaki yokuphumla koxinzelelo lwangaphakathi, nto leyo eyenza ukuba ifaneleke kakhulu kwiindlela ezichanekileyo kakhulu nezihlala ixesha elide.

Ukongeza kuzinzo olunemilinganiselo, igranite inika ukudambisa okugqwesileyo kokungcangcazela kunye nokwanda okuphantsi kobushushu. Ezi mpawu zinegalelo ekuphuculweni kokusebenza okuguquguqukayo, ukunciphisa ukushukuma kobushushu, kunye nokuchaneka okuhlala kusenzeka ngamaxesha angaphezulu okusebenza. Igranite ikwayiyo imagnethi kwaye ayimelani nokugqwala, ivumela ukusetyenziswa kwiindawo zokucoca, iinkqubo ze-optical, kunye neendawo zokuhlola ngokuchanekileyo.

Ipleyiti Yomphezulu Wegranite: Isiseko Sereferensi Yokuchaneka

Ipleyiti yomphezulu wegranite yenye yezona zibalulekileyo neziyaziwayoizinto zegranite ezichanekileyoIsebenza njengesicwangciso esithe tyaba, ixhasa ukuhlolwa kobukhulu, ukulinganiswa, kunye neenkqubo zokuhlanganisa kumashishini okuvelisa.

Iipleyiti zomphezulu wegranite zisetyenziswa kakhulu kwiilebhu zolawulo lomgangatho, kwiindawo zokuhlola imveliso, kunye namagumbi e-metrology. Ukumelana nokuguguleka kwazo kunye nokuzinza kwazo kuvumela ukuba zigcine ukuchaneka ubomi obude benkonzo kunye nokugcinwa okuncinci. Xa kuthelekiswa neepleyiti zomphezulu wesinyithi esityhidiweyo, iipleyiti zegranite zibonelela ngokumelana nokugqwala okuphezulu, uvakalelo oluphantsi lobushushu, kunye nokuphindaphinda okuncitshisiweyo.

Kwiindawo zokuvelisa eziphambili, iipleyiti zomphezulu wegranite ziya kuhlanganiswa ngakumbi kwiindibano zoomatshini, iiplatifomu ze-optical, kunye nezikhululo zokuhlola ezenzekelayo, nto leyo eyandisa indima yazo ngaphaya kwezixhobo zemveli ze-metrology ezizimeleyo.

Imbono yokuthelekisa: Ukukhethwa kwezinto ezisetyenziswa kwiziseko zoomatshini

Xa kuthelekiswa iziseko zoomatshini be-epoxy granite, iziseko zezixhobo zoomatshini besinyithi, kunye neendibano ze-granite ezichanekileyo, ukukhethwa kwezinto kufuneka kulawulwe ziimfuno zesicelo endaweni yeendleko zokuqala zodwa.

I-Epoxy granite inika ukuguquguquka koyilo kunye nokunciphisa ubushushu, okwenza ukuba ifaneleke kwiimashini ezinobuthathaka bokungcangcazela kodwa ezichanekileyo. Isinyithi esitshisiweyo sihlala sisebenza kwizixhobo zoomatshini eziqhelekileyo apho ukusebenza kakuhle kweendleko kunye neenkqubo zokuvelisa ezimiselweyo zizinto eziphambili. Nangona kunjalo, iindibano ze-precision granite zibonelela ngozinzo olungenakuthelekiswa nanto lwexesha elide, ukusebenza kobushushu, kunye nokugcinwa kokuchaneka, nto leyo eyenza ukuba ibe sisisombululo esikhethwayo kwizixhobo ezinobunono obuphezulu kunye neenkqubo ze-metrology eziphambili.

Ukusebenza komjikelo wobomi yeyona ndlela ibalulekileyo yokuvavanya. Nangona utyalo-mali lokuqala kwi-precision granite assemblies lunokuba phezulu, ukugcinwa okunciphileyo, amaxesha amade okulinganisa, kunye nokuchaneka okuqhubekayo kudla ngokukhokelela kwixabiso eliphantsi lobunini.

Iindlela Zoshishino Nezicwangciso Zoyilo Eziguqukayo

Iindlela ezahlukeneyo zoshishino zikhawulezisa ukwamkelwa kwezakhiwo zoomatshini ezisekelwe kwi-granite. Ukukhula kokuveliswa kwe-semiconductor, i-optics, kunye nokucutshungulwa kwe-laser kuye kwabangela imfuno yamaqonga azinzileyo kakhulu anakho ukuchaneka kwe-sub-micron. Ukwenziwa kwezinto ngokuzenzekelayo kunye nokuveliswa kwedijithali kugxininisa ngakumbi imfuneko yeziseko zesakhiwo ezinokuthenjwa ezinokusebenza ngokuqhubekayo ngaphandle kokuhamba kancinci.

Abayili bezixhobo zoomatshini baya besamkela ngakumbi uyilo lwe-hybrid oludibanisa iziseko zegranite kunye nee-motor ezithe ngqo, ii-air bearing, kunye neenkqubo zolawulo eziphambili. Kule mimiselo, ii-granite assemblies zibonelela ngozinzo olufunekayo ukuze kufezekiswe ngokupheleleyo amandla okusebenza kweteknoloji yokunyakaza okuphezulu kunye nokulinganisa.

Amandla e-ZHHIMG kwiMveliso yeGranite echanekileyo

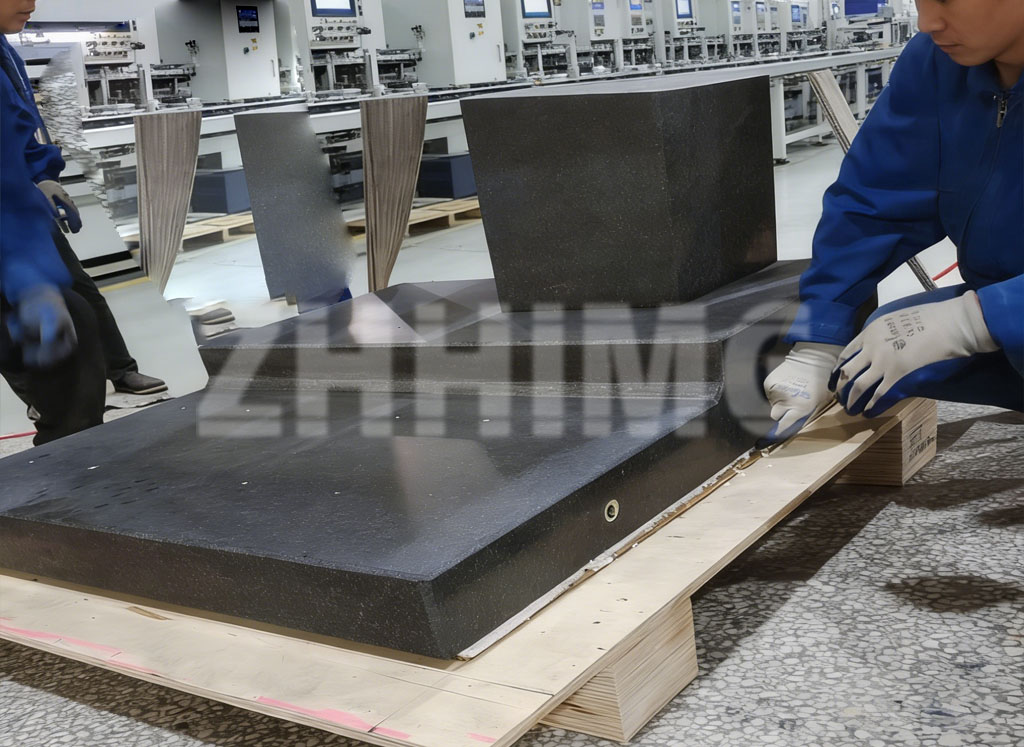

I-ZHHIMG igxile kuyilo kunye nokuveliswa kweendibano zegranite ezichanekileyo kubathengi bemizi-mveliso yehlabathi. Isebenzisa i-granite emnyama yeprimiyamu kunye nobuchwepheshe obuphambili bokugaya ngokuchaneka, i-ZHHIMG ivelisa iziseko zoomatshini begranite, iipleyiti zomphezulu, kunye neendibano ezenziwe ngokwezifiso ezihlangabezana nemigangatho engqongqo yokuchaneka kwamazwe ngamazwe.

Iinkqubo zokuvelisa zenkampani zenziwa phantsi kweemeko ezilawulwayo zendalo, kunye nokuhlolwa okubanzi kwinqanaba ngalinye ukuqinisekisa ukuhambelana nokuthembeka. I-ZHHIMG ixhasa abathengi kuyo yonke imveliso yezixhobo zoomatshini, iinkqubo zemetrology, izixhobo ze-semiconductor, kunye ne-automation ephucukileyo.

Ngokusebenzisana ngokusondeleyo nabayili bezixhobo kunye neenjineli, i-ZHHIMG inika izisombululo zegranite ezidityaniswe kakuhle kwiindlela zokwakha oomatshini ezintsonkothileyo kwaye zixhasa iinjongo zokusebenza kwexesha elide.

Isiphelo

Njengoko imveliso iqhubeka isiya kufikelela ekuchanekeni okuphezulu kunye nokuhlanganiswa okukhulu kwenkqubo, ukubaluleka kwezixhobo zesiseko somatshini kunye neendibano zesalathiso kuya kwanda kuphela. Iziseko zoomatshini be-granite ze-Epoxy kunye neziseko zezixhobo zomatshini zesinyithi ngasinye zigcina ukubaluleka ngaphakathi kweendawo ezithile zesicelo, kodwa iindibano ze-granite ezichanekileyo zibonelela ngeenzuzo ezahlukeneyo ekuzinzeni, ekuchanekeni, nasekusebenzeni komjikelo wobomi.

Iipleyiti zomphezulu wegranite kunye nezakhiwo zoomatshini ezisekelwe kwigranite zihlala zizinto ezisisiseko kubunjineli bokuchaneka kwanamhlanje. Ngobuchule obuzinikeleyo ekuveliseni igranite echanekileyo, i-ZHHIMG ikwindawo entle yokuxhasa abathengi behlabathi abafuna izisombululo ezithembekileyo nezihlala ixesha elide zemveliso ephucukileyo kunye nezicelo zemetrology.

Ixesha leposi: Jan-21-2026