Kwimeko eguquka ngokukhawuleza yemveliso ephucukileyo, ukuchaneka kuseyeyona ndawo iphambili. Namhlanje, uyilo olutsha oluphambili lumiselwe ukuchaza kwakhona imigangatho yeshishini: iPrecision Marble Three-Axis Gantry Platform, ummangaliso wobunjineli odibanisa uzinzo lwendalo lwegranite kunye noyilo loomatshini oluphambili ukuze kufezekiswe ukuchaneka kwinqanaba le-micron elalicingelwa ukuba alinakufumaneka kwizicelo zoshishino.

Isayensi Ebangela Uzinzo

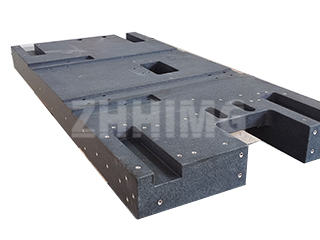

Eyona nto iphambili kule nkqubela yetekhnoloji kukhetho lwezinto ezingalindelekanga: igranite yendalo. Isiseko semabula esicwangcisiweyo seqonga le-1565 x 1420 x 740 mm asikobuhle boyilo kuphela—sisisombululo sesayensi kumceli mngeni wakudala wokugcina uzinzo kwiinkqubo ezichanekileyo. “I-coefficient ephantsi kakhulu yokwanda kobushushu begranite (2.5 x 10^-6 /°C) kunye neempawu ezingaqhelekanga zokudambisa zibonelela ngesiseko esimelana nokuguquguquka kobushushu bendalo kunye nokungcangcazela koomatshini ngcono kakhulu kunezakhiwo zesinyithi zemveli,” ucacisa uGqr. Emily Chen, injineli ephambili yoomatshini kwi-Precision Engineering Research Institute.

Le nzuzo yendalo iguqulela ngqo kwiimilinganiselo zokusebenza eziguqula iintloko kumashishini. Eli qonga lifikelela ekuphindaphindweni kwe-±0.8 μm—oko kuthetha ukuba linokubuyela nakweyiphi na indawo ngokuphambuka okuncinci kunobude bokukhanya okubonakalayo—kunye nokuchaneka kokubeka i-±1.2 μm emva kokuhlawula, okumisela umgangatho omtsha weenkqubo zokulawula intshukumo.

Ubuchule boBunjineli kwiNtshukumo

Ngaphaya kwesiseko sayo esizinzileyo, uyilo lwe-gantry yeqonga elinee-axis ezintathu lubandakanya izinto ezintsha ezininzi. I-X-axis inenkqubo ye-dual-drive esusa ukuguquguquka kwe-torsional ngexesha lokuhamba ngesantya esiphezulu, ngelixa zombini ii-X kunye ne-Y axes zibonelela ngokuhamba okusebenzayo kwe-750 mm kunye nokuthe tye kwe-≤8 μm kuzo zombini iiplani ezithe tye nezithe nkqo. Eli nqanaba lokuchaneka kwejometri liqinisekisa ukuba neendlela ze-3D ezintsonkothileyo zigcina ukuchaneka kwe-sub-micron.

Amandla okushukuma kwenkqubo alingana kakuhle phakathi kwesantya kunye nokuchaneka. Nangona isantya sayo esiphezulu se-1 mm/s sinokubonakala sincinci, yenzelwe ukusetyenziswa kwezicelo ezifuna ulawulo oluhle kunye nokuskena okucothayo—apho ukuchaneka kubaluleke ngaphezu kokuhamba ngokukhawuleza. Ngokwahlukileyo koko, amandla okukhawulezisa i-2 G aqinisekisa ukusebenza okukhawulezayo kokuqala, okubalulekileyo ekugcineni ukusebenza kweenkqubo zokuhlola ngokuchanekileyo.

Ngomthamo womthwalo ongama-40 kg kunye nesisombululo se-100 nm (0.0001 mm), eli qonga livala umsantsa phakathi kokusetyenziswa okuncinci okubuthathaka kunye nokuqina kwemizi-mveliso—ukuguquguquka okuvelisa umdla omkhulu kumacandelo okuvelisa.

Ukutshintsha Amashishini Abalulekileyo

Imiphumo yale mpumelelo yokuchaneka isasazeka kumacandelo amaninzi obuchwepheshe obuphezulu:

Kwimveliso ye-semiconductor, apho neziphene zesikali se-nanometer zinokwenza ii-chips zingabi namsebenzi, ukuzinza kweqonga kuguqula iinkqubo zokuhlolwa kwe-wafer kunye nokulungelelaniswa kwe-photolithography. “Sibona amazinga okuchongwa kweziphene ephucuka ngama-37% kuvavanyo lokuqala,” uxela uMichael Torres, injineli ephezulu yenkqubo kumvelisi ophambili wezixhobo ze-semiconductor. “Ukudambisa ukungcangcazela kwesiseko semabula kususe i-micro-wobble eyayisithe iimpawu ze-sub-50 nm ngaphambili.”

Ukwenziwa kwe-optical echanekileyo yenye inzuzo. Iinkqubo zokupolisha iilensi kunye nokuhlanganisa ezazikade zifuna iiyure zokulungiswa ngesandla ngokucokisekileyo ngokuziqhelanisa ne-sub-micron positioning yeqonga, zinciphisa amaxesha okuvelisa ngelixa ziphucula ukusebenza kwe-optical.

Kuphando lwe-biomedical, eli qonga livumela impumelelo ekusetyenzisweni kweseli enye kunye nemifanekiso ye-microscopic enesisombululo esiphezulu. UGqr. Sarah Johnson weSebe lezoBunjineli bezoBomi eStanford uthi, “Uzinzo lusenza sikwazi ukugcina ingqwalasela kwizakhiwo zeseli ixesha elide, sithatha imifanekiso yexesha elidlulayo ebonisa iinkqubo zebhayoloji ezazifihliwe ngaphambili kukushukuma kwezixhobo.”

Ezinye izicelo eziphambili ziquka oomatshini bokulinganisa abachanekileyo (ii-CMM), ukupakishwa kwe-microelectronics, kunye nezixhobo zophando lwesayensi eziphambili-zonke iindawo apho indibaniselwano eyahlukileyo yeqonga yokuchaneka, ukuzinza, kunye nomthamo womthwalo ijongana nemida yobugcisa ekudala ikho.

Ikamva Lokwenziwa Kwemveliso Ngobuchule Obuphezulu

Njengoko imveliso iqhubeka nokuqhubela phambili kwayo okungapheliyo ukuya kwi-miniaturization kunye nemigangatho ephezulu yokusebenza, imfuno yeenkqubo zokubeka izinto ngendlela echanekileyo kakhulu iya kukhula ngakumbi. I-Precision Marble Three-Axis Gantry Platform ayimeli nje kuphela uphuculo oluqhubekayo kodwa utshintsho olubalulekileyo kwindlela olufezekiswa ngayo uluchaneko—ukusebenzisa iipropati zezinto zendalo kunye nobunjineli obuphambili endaweni yokuxhomekeka kuphela kwiinkqubo zembuyekezo ezisebenzayo ezintsonkothileyo.

Kubavelisi abajongene nemingeni ye-Industry 4.0, eli qonga linika umbono wekamva lobunjineli bokuchaneka. Likamva apho umda phakathi "kokuchaneka kwelebhu" kunye "nemveliso yemizi-mveliso" uqhubeka ungacaci, nto leyo evumela uphuhliso olutsha oluya kuyila yonke into ukusuka kwizixhobo ze-elektroniki zesizukulwana esilandelayo ukuya kwizixhobo zonyango ezisindisa ubomi.

Njengoko omnye umhlalutyi weshishini watshoyo: “Kwihlabathi lokuvelisa ngokuchanekileyo, uzinzo aluyonto nje ibalulekileyo—lusisiseko apho zonke ezinye izinto eziphucukileyo zakhiwe khona. Eli qonga aliphakamisi nje kuphela; liyakha kwakhona ngokupheleleyo.”

Ixesha leposi: Oktobha-31-2025