Kwintsimi enkulu yokuvelisa ngokuchanekileyo kunye nophando lwesayensi oluphambili, iqonga lomoya oxinzelelweyo oluhambelanayo oluhambayo olunezakhono zokulawula intshukumo ezichanekileyo lithatha indawo ebalulekileyo, kwaye intsikelelo yesiseko sokuchaneka kwegranite, kodwa kwakhona ivumela ukusebenza kwayo njengamaphiko engwe, ukuba kudlale indima kwiinkalo ezininzi.

Ukuveliswa kwee-semiconductor: isiqinisekiso esiphambili sokuchaneka kweetship

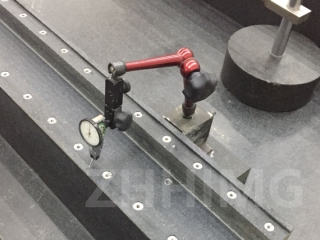

Ukwenziwa kweetshiphusi ze-semiconductor kubizwa ngokuba yi-"crown jewel" yetekhnoloji yanamhlanje, kwaye iimfuno zokuchaneka kwenkqubo nganye zifikelele kwinqanaba elinzima kakhulu. Kwisigaba se-photolithography, ipateni yesekethe kwi-chip kufuneka idluliselwe kumphezulu we-wafer ngokuchanekileyo kwe-nanometer. Iqonga lokudada lomoya oxinzelelweyo oluchanekileyo olunesiseko se-granite ngokuchanekileyo, linokubonelela ngenkxaso ezinzileyo kakhulu kunye nolawulo oluchanekileyo lokushukuma. Uzinzo oluhle kakhulu lwesiseko se-granite lukhusela ngokufanelekileyo ukuphazamiseka kokungcangcazela kwangaphandle, kwaye i-coefficient yayo yokwandiswa ephantsi iqinisekisa uzinzo olulinganayo xa ubushushu butshintshatshintsha, ukuze ukuchaneka kokubekwa kwe-wafer kube yi-nanometers. Olu phawu luchanekileyo lubonelela ngesiseko esiqinileyo sezixhobo ze-lithography ukuze zidwebe ngokuchanekileyo iipateni zesekethe, ziphucule kakhulu ukuhlanganiswa kweetshiphusi kunye nemveliso, zincede ishishini le-semiconductor liqhubeke nokugqitha umda wenkqubo, lenze iitshiphusi ezinamandla ngakumbi, ezincinci, ezisetyenziswa kakhulu kwiifowuni ezihlakaniphileyo, iikhompyutha, ubukrelekrele bokwenziwa kunye nezinye iindawo, kwaye zikhuthaze uphuhliso oluqhubekayo lwezixhobo ze-elektroniki ukuya ekusebenzeni okuncinci kunye nokusebenza okuphezulu.

Ukwenziwa kwemveliso echanekileyo yokubona: Ukukrola isiseko sombono ocacileyo

Ukwenziwa kweelensi ze-optical, iilensi kunye nezinye izinto kufuna ukuchaneka okuphezulu kakhulu komphezulu kunye nokuchaneka kwesimo, kwaye naziphi na iziphene ezincinci zinokuchaphazela umgangatho wemifanekiso ye-optical. Isiseko se-granite esichanekileyo somoya oshukumayo ochanekileyo sidlala indima ebalulekileyo kweli candelo. Ngexesha lenkqubo yokusila ilensi, iqonga linokuqhuba isixhobo sokusila ukuba sicubungule umphezulu welensi nge-micron okanye ukuchaneka kwe-sub-micron, ukuqinisekisa ukuba ukuthamba komphezulu welensi kuyahlangabezana neemfuno zoyilo. Uzinzo oluphezulu lwesiseko se-granite luqinisekisa ukuchaneka kwendawo ehambelanayo yelensi kunye nesixhobo sokusila ngexesha lenkqubo yokusila, kuthintelwe iimpazamo zokusila ezibangelwa kukungcangcazela okanye ukufuduka. Kwinkqubo yokusila, inkxaso yayo ezinzileyo ivumela izixhobo zokusila ukuba zisebenzise amandla afanayo, zidala iilensi ze-optical ezicacileyo neziphantsi. Ezi lensi zisemgangathweni ophezulu zisetyenziswa kakhulu kwizixhobo zeefoto eziphezulu, iimakroskopu zonyango, iiteleskopu zeenkwenkwezi kunye nezinye izixhobo ze-optical, zibonelela ngehlabathi elibonakalayo elicacileyo nelinobuthathaka ebantwini, kodwa zikwabonelela ngezinto eziphambili ze-optical zokuxilonga ngezonyango, ukujonga izinto zasezulwini kunye neminye imisebenzi yophando lwesayensi, zinceda ekuhloleni imfihlakalo yehlabathi elincinci nelikhulu.

Ukwenziwa kweenqwelo-moya: Inkxaso eqinileyo yokusebenza kweenqwelo-moya

Ukwenziwa kweenqwelo-moya kunxulumene nokhuseleko lwesizwe kunye namandla esayensi kunye nobuchwepheshe, kwaye ukuchaneka kwamalungu kungqongqo kakhulu. Isiseko sokuchaneka kwegranite seqonga lokuhamba lomoya oxinzelelweyo oqinileyo sibaluleke kakhulu ekusetyenzisweni kweblade yenjini ye-aero kunye nokuveliswa kwamacandelo olwakhiwo lweenqwelo-moya. Xa kusetyenzwa iiblade zenjini ye-aero, kuyimfuneko ukulawula ngokuchanekileyo indlela yesixhobo ukuqinisekisa ukuba ukuchaneka kweprofayili yeblade kuhlangabezana nomgangatho woyilo, ochaphazela ngokuthe ngqo ukusebenza kakuhle kokutsha kunye nokutyhala kwenjini. Iqonga lokuhamba lomoya oxinzelelweyo oxinzelelweyo oxhaswa sisiseko sokuchaneka kwegranite linokuphumeza ulawulo lokuhamba oluchanekileyo, ukuze isixhobo sikwazi ukusika ngokuchanekileyo izinto zeblade kwaye siqinisekise umgangatho weblade. Ekwenzeni kwamacandelo olwakhiwo lweenqwelo-moya, nokuba kukubhola, ukugaya okanye ukuhlanganisa, indawo echanekileyo kunye nokuhamba okuzinzileyo kweqonga kuqinisekisa ukuchaneka kobukhulu kunye nokuchaneka kokuhlanganiswa kwamacandelo olwakhiwo, ukuphucula amandla olwakhiwo ngelixa kunciphisa ubunzima benqwelo-moya, ukuphucula ukhuseleko kunye nokusebenza kwenqwelo-moya, kunye nokubonelela ngesiqinisekiso sokuvelisa esiqinileyo sophuhliso lweshishini leenqwelo-moya. Ukukhuthaza ukuphononongwa kwabantu kwesibhakabhaka kunye nendalo iphela.

Uphando lwezonyango: isandla sasekunene sokuhlola iimfihlakalo zobomi

Kwicandelo lophando lwezonyango, ukusebenza ngokuchanekileyo kunye nokujonga iisampuli zemicroscopic sisitshixo sokuvula imfihlakalo yobomi kunye nokoyisa izifo ezinzima. Iqonga lokudada lomoya oxineneyo oluqinileyo olunesiseko segranite esichanekileyo lidlala indima ebalulekileyo ekulandeleni iijini, ukuphathwa kweeseli ezincinci njalo njalo. Kwizixhobo zokulandelelanisa iijini, iqonga linokuhambisa ngokuchanekileyo islayidi yesampulu, ukuze isixhobo sokulandelelanisa sikwazi ukufunda ngokuchanekileyo ulwazi lwejini, siphucule ukuchaneka nokusebenza kakuhle kokulandelelanisa iijini, kwaye sinike inkxaso enamandla yokuxilongwa kwejini kunye nonyango lomntu ngamnye lwezifo. Kwindlela yokulawula iiseli ezincinci, abaqhubi basebenzisa iqonga ukulawula ngokuchanekileyo ii-microneedles, ii-microstraws kunye nezinye izixhobo zokufaka kunye nokukhupha iiseli nganye, kunceda uphando oluphambili olufana nebhayoloji yeeseli kunye nonyango lwejini, ukubonelela ngenkxaso yobugcisa ebalulekileyo kwintsha kunye nophuhliso lwetekhnoloji yezonyango, kunye nokuzisa ithemba elitsha kwimpilo yabantu.

Ngenxa yokuchaneka kwayo okugqwesileyo, ukuzinza kunye nokuqina, isiseko sokuchaneka kwegranite seqonga lokudada elichanekileyo lomoya siye saba yinkxaso ephambili kwiindawo ezininzi ezineemfuno zokuchaneka okuphezulu, kwaye iyaqhubeka nokukhuthaza uphuhliso lwamashishini ahlukeneyo ukuya kwicala elinobungcali ngakumbi, ifaka impembelelo enamandla kwinkqubela phambili yesayensi netekhnoloji kunye nophuhliso loluntu.

Ixesha lokuthumela: Epreli-10-2025