Kwimveliso echanekileyo, uvavanyo lophando lwesayensi kunye nezinye iimfuno ezichanekileyo zentsimi, iqonga elihambayo lomoya oxinzelelweyo lidlala indima ebalulekileyo. Ukukhetha isiseko seqonga, njengokubeka ilitye lembombo lesakhiwo, kunxulumene ngqo nokusebenza kweqonga. Isiseko esichanekileyo segranite kunye nesiseko sokuphosa izimbiwa njengeendlela ezimbini ezidumileyo, nganye inezibonelelo zayo, oku kulandelayo kukuthelekisa okuneenkcukacha.

Uzinzo: Umahluko phakathi kwekristale yendalo kunye ne-composite yokwenziwa

Isiseko sokuchaneka kwegranite emva kwezigidi zeminyaka yotshintsho lwejoloji, i-quartz yangaphakathi, i-feldspar kunye nezinye iiminerali ziqinile ngekristale, isakhiwo sixinene kakhulu kwaye siyafana. Xa kukho ukuphazamiseka kwangaphandle, njengokungcangcazela okubangelwa kukusebenza kwezixhobo ezinkulu ezijikelezileyo, isiseko segranite sifana nesikhuselo esiqinileyo, esinokuvimba kwaye sinciphise ngempumelelo, kwaye sinokunciphisa ubukhulu bokungcangcazela kweqonga lomoya oxinzelelweyo ohambayo ngaphezulu kwe-80%, sibonelela ngesiseko esiqinileyo nesizinzileyo sokuhamba ngokuchanekileyo kweqonga. Kwiworkshop yokwenziwa kweetshiphu ze-semiconductor, inkqubo ye-lithography ineemfuno eziphezulu zokuzinza kweqonga, kwaye isiseko segranite siqinisekisa ukusebenza ngokuchanekileyo kwezixhobo ze-chip lithography, sinceda ukukrola ngokuchanekileyo kwepateni yetshiphu, kwaye siphucula kakhulu imveliso yokwenziwa kweetshiphu.

Isiseko sokuphosa izimbiwa senziwe ngamasuntswana eeminerali axutywe ne-binder ekhethekileyo. Ulwakhiwo lwangaphakathi lwayo lufana kwaye ineempawu ezithile zokudambisa ukungcangcazela. Xa ijongene nokungcangcazela ngokubanzi, inokubonelela ngendawo yokusebenza ezinzileyo yeqonga. Nangona kunjalo, xa ijongene nokuqina okuphezulu kunye nokungcangcazela okuqhubekayo, amandla okuncitshiswa kokungcangcazela kwesiseko sokuphosa izimbiwa awanelanga kancinci xa kuthelekiswa nesiseko segranite, oku kunokukhokelela ekuphambukeni okuncinci kwentshukumo yeqonga kwaye kuchaphazele ukuchaneka kokusebenza okuchanekileyo kakhulu.

Ukugcinwa kokuchaneka: ibhalansi yeenzuzo zendalo kunye nolawulo lokwenziwa kokwandiswa okuphantsi

I-Granite yaziwa ngomlinganiselo wayo ophantsi kakhulu wokwandiswa kobushushu, ngokubanzi yi-5-7 × 10⁻⁶/℃. Kwimeko yobushushu obutshintshatshintshayo, ubungakanani besiseko sokuchaneka kwe-granite abutshintshi kangako. Kwicandelo le-astronomy, iqonga lokuhamba komoya oxinzelelweyo we-static pressure pressure lokulungisa kakuhle ilensi yeteleskopu lidibene nesiseko se-granite, nokuba umahluko wobushushu phakathi kwemini nobusuku ubalulekile, inokuqinisekisa ukuba ukuchaneka kwendawo yelensi kugcinwa kwinqanaba le-submicron, inceda izazi ngeenkwenkwezi ukuba zibambe utshintsho oluncinci lwezinto ezikude zasezulwini.

Kuyilo lwezixhobo zokuphosa izimbiwa, iimpawu zokwandisa ubushushu zinokulungiswa kwaye zilawulwe, kwaye i-coefficient yokwandisa ubushushu ingaba kufutshane okanye ingcono kune-granite ngokulungelelanisa umlinganiselo weeminerali kunye nee-binders. Kwezinye izixhobo zokulinganisa ezibuthathaka kubushushu, ezichanekileyo kakhulu, isiseko se-mineral cast sinokugcina ubungakanani obuzinzileyo xa ubushushu butshintsha, ukuqinisekisa ukuchaneka kokuhamba kweqonga. Nangona kunjalo, isiseko se-mineral cast sichaphazeleka zizinto ezifana nokwaluphala kwe-binder, kwaye ukuzinza kokuchaneka kwexesha elide kufuneka kujongwe ngakumbi.

Ukuqina: Iimpawu zelitye lendalo eliqinileyo kakhulu kunye nezinto ezidityanisiweyo ezimelana nokudinwa

Ubunzima begranite buphezulu, ubunzima beMohs bunokufikelela kwi-6-7, kunye nokumelana okuhle kokuguguleka. Kwilabhoratri yesayensi yezinto, iqonga lomoya ohambayo ochanekileyo osetyenziswa rhoqo, isiseko salo segranite sinokumelana ngempumelelo nokulahleka kokungqubana kwexesha elide, xa kuthelekiswa nesiseko esiqhelekileyo, sinokwandisa umjikelo wokugcinwa kweqonga ngaphezulu kwe-50%, sinciphise iindleko zokugcinwa kwezixhobo, kwaye siqinisekise ukuqhubeka komsebenzi wophando lwesayensi. Nangona kunjalo, izinto zegranite zibuthathaka kwaye kulula ukuziqhekeza xa zichaphazeleka ngengozi.

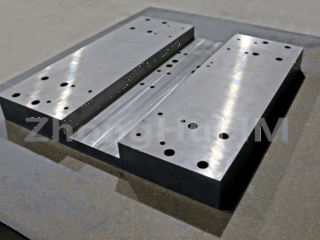

Isiseko sokuphosa izimbiwa sineempawu ezintle kakhulu zokulwa nokudinwa, ezinokumelana ngempumelelo nomonakalo wokudinwa kwaye zigcine ulungelelwaniso lwesakhiwo ngexesha lokuhamba kwexesha elide okuphindaphindeneyo kweqonga lomoya oxinzelelweyo ochanekileyo. Kwangaxeshanye, sinokuxhathisa okuthile kwiikhemikhali eziqhelekileyo, kwaye kwimeko enomngcipheko omncinci wokugqwala kweekhemikhali, ihlala ixesha elide kunesiseko segranite. Nangona kunjalo, kwiindawo ezigqithisileyo ezifana nokufuma okuphezulu, i-binder kwisiseko se-mineral cast inokuchaphazeleka, okunciphisa ukuqina kwayo.

Ubunzima beendleko zokuvelisa kunye nokucubungula: Imingeni yelitye lendalo kunye nemida yokwenziwa kwesinyithi

Ukumbiwa nokuthuthwa kwezinto eziluhlaza zegranite kuyinkimbinkimbi, kwaye ukucutshungulwa kufuna izixhobo kunye nobuchwepheshe obuphezulu kakhulu. Ngenxa yobunzima bayo obuphezulu kunye nokuqhekeka, kulula ukuba neengxaki ezifana nokuwa komphetho kunye nokuqhekeka ekusikeni, ekugayeni, ekupolisheni nakwezinye iinkqubo, kwaye izinga leenkunkuma liphezulu kakhulu, nto leyo ebangela iindleko eziphezulu zokuvelisa.

Ukwenziwa kwesiseko sokuphosa izimbiwa kufuna isikhunta esithile kunye nenkqubo, kwaye iindleko zophuhliso lwesikhunta kwangoko ziphezulu, kodwa xa isikhunta senziwe, imveliso enkulu inokufezekiswa kwaye iindleko zeyunithi zinokuncitshiswa. Inkqubo yayo yokucubungula ilula xa ithelekiswa negranite, kwaye inokufezekisa iimfuno ezichanekileyo eziphezulu ngeendlela zokucubungula ngoomatshini, kwaye inamandla okusebenzisa imali eninzi kwiimeko zokusetyenziswa okukhulu.

Ixesha lokuthumela: Epreli-10-2025