Kwicandelo lovavanyo lwe-semiconductor, ukukhethwa kwezinto zeqonga lovavanyo kudlala indima ebalulekileyo ekuchanekeni kovavanyo kunye nokuzinza kwezixhobo. Xa kuthelekiswa nezinto zesinyithi zemveli, i-granite iba lolona khetho lufanelekileyo kumaqonga ovavanyo lwe-semiconductor ngenxa yokusebenza kwayo okugqwesileyo.

Ukumelana nokugqwala okugqwesileyo kuqinisekisa ukusebenza okuzinzileyo kwexesha elide

Ngexesha lenkqubo yovavanyo lwe-semiconductor, ii-reagents ezahlukeneyo zeekhemikhali zihlala zibandakanyeka, ezifana nesisombululo se-potassium hydroxide (KOH) esisetyenziselwa uphuhliso lwe-photoresist, kunye nezinto ezirhabaxa kakhulu ezifana ne-hydrofluoric acid (HF) kunye ne-nitric acid (HNO₃) kwinkqubo yokugrumba. I-Cast iron yenziwe ikakhulu zizinto zesinyithi. Kwimeko enjalo yeekhemikhali, ii-reactions zokunciphisa i-oxidation zinokwenzeka kakhulu. Ii-athomu zesinyithi zilahlekelwa zii-electron kwaye zenze ii-reactions zokufuduka kunye nezinto ezine-asidi kwisisombululo, nto leyo ebangela ukugruzuka ngokukhawuleza komphezulu, zenze umhlwa kunye nokuxinana, kwaye zonakalise ukuchaneka kunye nobukhulu beqonga.

Ngokwahlukileyo koko, ukwakheka kwezimbiwa zegranite kuyinika ukumelana nokugqwala okumangalisayo. Icandelo layo eliphambili, i-quartz (SiO₂), ineempawu zeekhemikhali ezizinzileyo kakhulu kwaye ayisebenzi kangako kwii-asidi eziqhelekileyo kunye neziseko. Iiminerali ezifana ne-feldspar nazo azinamsebenzi kwiindawo zeekhemikhali ngokubanzi. Inani elikhulu lovavanyo lubonise ukuba kwindawo efanayo yeekhemikhali zokufumanisa i-semiconductor, ukumelana nokugqwala kweekhemikhali zegranite kungaphezulu ngokuphindwe ka-15 kunokwesinyithi esityhidiweyo. Oku kuthetha ukuba ukusebenzisa amaqonga egranite kunokunciphisa kakhulu ukuphindaphindeka kunye neendleko zokugcinwa kwezixhobo ezibangelwa kukugqwala, kwandise ubomi benkonzo yezixhobo, kwaye kuqinisekise uzinzo lwexesha elide lokuchaneka kokufunyanwa.

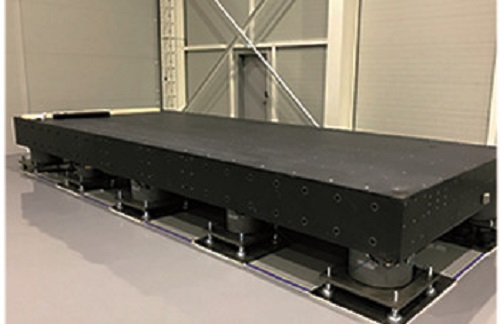

Uzinzo oluphezulu kakhulu, oluhlangabezana neemfuno zokuchaneka kokufunyanwa kwinqanaba le-nanometer

Uvavanyo lwe-semiconductor luneemfuno eziphezulu kakhulu zokuzinza kweqonga kwaye lufuna ukulinganisa ngokuchanekileyo iimpawu zetship kwi-nanoscale. I-coefficient yokwandiswa kobushushu besinyithi esityhidiweyo iphezulu, malunga ne-10-12 × 10⁻⁶/℃. Ubushushu obuveliswa kukusebenza kwezixhobo zokufumanisa okanye ukuguquguquka kobushushu obujikeleze umhlaba buya kubangela ukwanda okukhulu kobushushu kunye nokucutheka kweqonga lesinyithi esityhidiweyo, okubangela ukuphambuka kwesimo phakathi kweprobe yokufumanisa kunye netship kwaye kuchaphazele ukuchaneka kokulinganisa.

I-coefficient yokwandiswa kobushushu begranite yi-0.6-5×10⁻⁶/℃ kuphela, eyincinci okanye engaphantsi kuneyesinyithi esityhidiweyo. Ulwakhiwo lwayo luxineneyo. Uxinzelelo lwangaphakathi luye lwasuswa ngokuyintloko ngenxa yokwaluphala kwendalo ixesha elide kwaye luchaphazeleka kancinci kutshintsho lobushushu. Ukongeza, igranite inobulukhuni obuqinileyo, obunobunzima obuphindwe kabini ukuya kwesithathu obuphezulu kunobo besinyithi esityhidiweyo (elingana ne-HRC > 51), enokumelana ngempumelelo neempembelelo zangaphandle kunye nokungcangcazela kwaye igcine ukuthamba kunye nokuthe tye kweqonga. Umzekelo, ekufumaneni isekethe yetshiphu echanekileyo kakhulu, iqonga legranite linokulawula impazamo yokuthamba ngaphakathi kwe-±0.5μm/m, ukuqinisekisa ukuba izixhobo zokufumanisa zisenokufumana ukufunyanwa kokuchaneka kwe-nanoscale kwiindawo ezintsonkothileyo.

Ipropati ebalaseleyo yokulwa nemagnethi, edala indawo yokubhaqwa ecocekileyo

Izixhobo ze-elektroniki kunye nee-sensors kwizixhobo zovavanyo lwe-semiconductor zinobuthathaka kakhulu kuphazamiseko lwe-electromagnetic. Isinyithi esitshisiweyo sinomlinganiselo othile wemagnetism. Kwimeko-bume ye-electromagnetic, iya kuvelisa intsimi yemagnethi ebangelwayo, eya kuphazamisana nemiqondiso ye-electromagnetic yezixhobo zokufumanisa, nto leyo ekhokelela ekuphazamisekeni kwesignali kunye nedatha yokufumanisa engaqhelekanga.

Kwelinye icala, igranite yinto echasene nemagnethi kwaye ayidibani kakhulu nemimandla yemagnethi yangaphandle. Ii-electron zangaphakathi zikhona ngababini ngaphakathi kweebhondi zeekhemikhali, kwaye isakhiwo sizinzile, asichaphazeleki ngamandla e-electromagnetic angaphandle. Kwindawo enamandla ye-magnetic field ye-10mT, amandla e-magnetic field abangelwayo kumphezulu wegranite angaphantsi kwe-0.001mT, ngelixa lawo akwindawo yesinyithi esityhidiweyo aphezulu ngaphezu kwe-8mT. Olu phawu luvumela iqonga legranite ukuba lenze indawo ye-electromagnetic ecocekileyo yezixhobo zokufumanisa, ngakumbi ezifanelekileyo kwiimeko ezineemfuno ezingqongqo zengxolo ye-electromagnetic efana nokufunyanwa kwe-quantum chip kunye nokufunyanwa kwesekethe ye-analog echanekileyo kakhulu, okuphucula ngempumelelo ukuthembeka kunye nokuhambelana kweziphumo zokufumanisa.

Ekwakhiweni kwamaqonga ovavanyo lwe-semiconductor, i-granite idlule ngokupheleleyo kwizixhobo zesinyithi ngenxa yeenzuzo zayo ezibalulekileyo ezifana nokumelana nokugqwala, ukuzinza kunye nokuchasana nombane. Njengoko iteknoloji ye-semiconductor iqhubela phambili ukuya ekuchanekeni okuphezulu, i-granite iya kudlala indima ebaluleke ngakumbi ekuqinisekiseni ukusebenza kwezixhobo zovavanyo kunye nokukhuthaza inkqubela phambili kushishino lwe-semiconductor.

Ixesha leposi: Meyi-15-2025