Kwicandelo lokulinganisa ngokuchanekileyo, ukuchaneka kokulinganisa komatshini wokulinganisa onamakhonkco amathathu (CMM) kuchaphazela ngokuthe ngqo ukuthembeka kweziphumo zokulinganisa. Iirula zegranite ezichanekileyo ze-1μm, ngenxa yeempawu zazo zomzimba ezizinzileyo kunye nokuchaneka okuphezulu kakhulu kokuvelisa, ziye zaba zizixhobo ezifanelekileyo zokulinganisa oomatshini bokulinganisa abanamakhonkco amathathu. Oku kulandelayo kuya kukunika intshayelelo eneenkcukacha kumanyathelo athile okulinganisa umatshini wokulinganisa onamakhonkco amathathu usebenzisa irula yegranite echanekileyo ye-ZHHIMG® 1μm.

I. Amalungiselelo ngaphambi kokulinganisa

Jonga iimeko zokusingqongileyo: Qinisekisa ukuba ubushushu bendawo yokulinganisa buzinzile kwi-20±1℃, kwaye umswakama ulawulwa phakathi kwe-40% kunye ne-60%. Kwangaxeshanye, nciphisa ukuphazamiseka kokungcangcazela okubangelwa kukuhamba kwabasebenzi kunye nokusebenza kwezixhobo. Imigangatho yokusingqongileyo ye-workshop yobushushu obungaguqukiyo kunye nomswakama ye-ZHHIMG® yenzelwe ngokuchanekileyo ukuqinisekisa ukuba iimveliso ze-granite azichaphazeleki ziimeko zokusingqongileyo ngexesha lenkqubo yemveliso. Oku kukwangqina ngokungangqalanga ukubaluleka kweemeko zokusingqongileyo ukuze kulinganiswe ngokuchanekileyo.

Izixhobo zokucoca: Sebenzisa ilaphu elingena-lint kunye nesicoci esikhethekileyo ukuze usule ngononophelo itafile yokusebenza, iprobe kunye nomphezulu we-granite ruler yomatshini wokulinganisa onama-three-coordinate ukuqinisekisa ukuba akukho luthuli, amabala eoyile okanye ezinye izinto ezingcolileyo, ukuze zingachaphazeli ukuchaneka kokulinganisa.

Qinisekisa isatifikethi kunye nesimo: Qinisekisa ukuba isatifikethi sokulinganisa esiqhotyoshelwe kwi-granite ruler sikwixesha laso lokusebenza, kwaye akukho mikrwelo icacileyo, umonakalo okanye ezinye iziphene kumphezulu we-ruler. Yonke imveliso ye-ZHHIMG® ivavanywa ngokungqongqo kwaye ixhotyiswe ngeziqinisekiso zovavanyo ezigunyazisiweyo ukuqinisekisa ukuba ukuchaneka kwemveliso kuyahlangabezana nemigangatho.

Ii. Amanyathelo Okusebenza Kokulinganisa

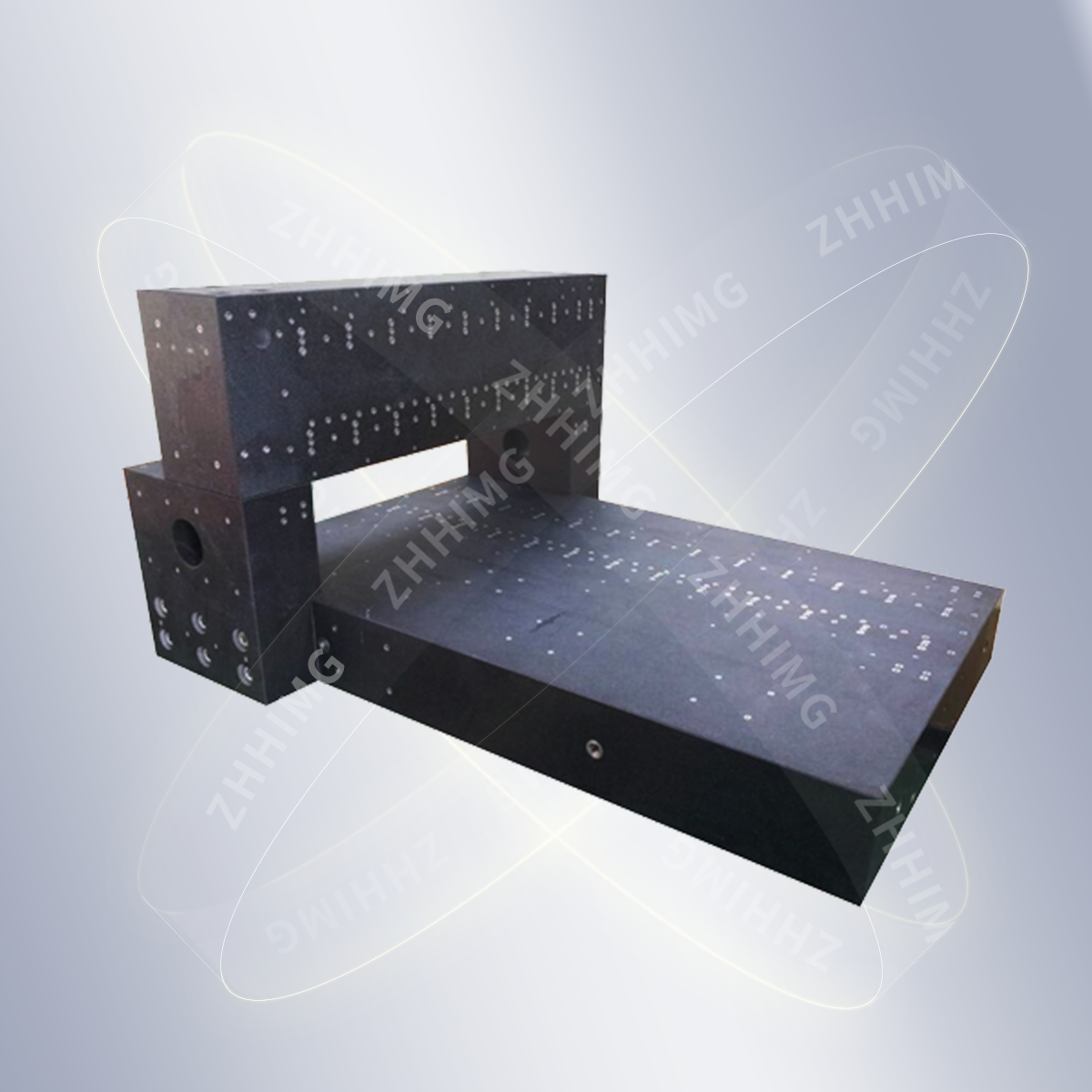

Beka irula yegranite: Beka irula yegranite echanekileyo eyi-1μm ngokuthe chu kwitafile yokusebenza yomatshini wokulinganisa onama-three-coordinate, uze uzame ukuyenza ihambelane nee-coordinate axes zomatshini wokulinganisa. Sebenzisa isixhobo esikhethekileyo okanye isiseko semagnethi ukuyilungisa ukuze uthintele irula ukuba ingashukumi ngexesha lenkqubo yokulinganisa.

Ukuqaliswa kweprobe kunye nokubekwa kwayo: Qalisa umatshini wokulinganisa onama-three-coordinate kwaye wenze imisebenzi yokuqalisa kwiprobe ukuqinisekisa ukuba ikwimeko yokusebenza eqhelekileyo. Emva koko, lawula intloko yokulinganisa yomatshini wokulinganisa ukuba ihambe kancinci ngaphezulu kwendawo yokulinganisa yokuqala yerula yegranite, ulungiselela ukulinganisa.

Thabatha ixabiso eliqhelekileyo lokulinganisa amanqaku amaninzi: Kumacala obude berula yegranite, khetha ngokulinganayo ubuncinane amanqaku amahlanu okulinganisa (njengendawo yokuqala, inqaku eli-1/4, inqaku eliphakathi, inqaku eli-3/4, kunye nenqaku lokugqibela), lawula iprobe ukuze wenze umlinganiselo woqhagamshelwano kwindawo nganye yokulinganisa ngokulandelelana, kwaye urekhode idatha yokulinganisa yenqaku ngalinye. Ukuchaneka okuphezulu kwe-ZHHIMG® granite straightedges kunokuqinisekisa ukuba le datha yokulinganisa ibonisa ngokwenene imeko yokuchaneka komatshini wokulinganisa.

Ukubalwa kweempazamo kunye nokulinganiswa: Thelekisa idatha erekhodwe ngumatshini wokulinganisa kunye nexabiso eliqhelekileyo lerula yegranite ukuze kubalwe ixabiso lempazamo yenqaku ngalinye lokulinganisa. Ngokwemeko yempazamo, inkqubo yokulungelelanisa yomatshini wokulinganisa onezihlanganisi ezintathu iyalungiswa kwaye ilinganiswe ngokufanelekileyo ngokusebenzisa isoftware yokulinganisa yomatshini wokulinganisa onezihlanganisi ezintathu de impazamo yokulinganisa ilawulwe ngaphakathi koluhlu oluvumelekileyo.

Ukuqinisekiswa kokulinganisa okuphindaphindiweyo: Emva kokuba ukulinganisa kugqityiwe, yenza ukulinganisa kwamanqaku amaninzi kwi-granite ruler kwakhona ukuqinisekisa isiphumo sokulinganisa. Ukuba impazamo phakathi kwesiphumo sokulinganisa kunye nexabiso eliqhelekileyo lingaphakathi kwe-±1μm, ibonisa ukuba ukulinganisa kuphumelele. Ukuba impazamo inkulu kakhulu, amanyathelo okusebenza kufuneka ahlolwe kwakhona. Ukuba kuyimfuneko, nxibelelana neengcali ukuze zisingathe.

Iii. Ukugcinwa kunye namanyathelo okhuseleko emva koLungiso

Gcina irula ngokufanelekileyo: Emva kokuba umsebenzi wokulinganisa ugqityiwe, sula irula yegranite ngelaphu elicocekileyo elingenayo ilinti, uyibeke kwibhokisi yokupakisha okanye kwibhokisi yokukhusela, kwaye uyigcine kwindawo eyomileyo neyobushushu obungaguqukiyo ukuthintela irula ukuba ingafuma okanye yonakale.

Ukulinganisa rhoqo: Ukuqinisekisa ukuchaneka kokulinganisa ixesha elide komatshini wokulinganisa, kucetyiswa ukuba ulinganise umatshini wokulinganisa onama-three-coordinate nge-1μm precision granite ruler rhoqo kwiinyanga ezi-3 ukuya kwezi-6. Kwangaxeshanye, xa umatshini wokulinganisa uthuthwe, ugcinwa okanye utshintsho olukhulu kwiimeko zokusingqongileyo, ukulinganisa kufuneka kwenziwe ngexesha elifanelekileyo.

Ukusebenza okuqhelekileyo: Ngexesha lokusetyenziswa kwemihla ngemihla, landela ngokungqongqo iinkqubo zokusebenza ukuze usebenzise umatshini wokulinganisa onama-three-coordinate kunye ne-granite ruler ukuze uphephe ukonakala kwezixhobo okanye izixhobo ngenxa yokusebenza okungafanelekanga, okunokuchaphazela ukuchaneka kokulinganisa.

Ngala manyathelo angentla, i-ZHHIMG® 1μm precision granite ruler ingasetyenziswa ngokufanelekileyo ukulinganisa umatshini wokulinganisa onama-three-coordinate, ukuqinisekisa ukuchaneka nokuthembeka kweziphumo zawo zokulinganisa kunye nokubonelela ngesiqinisekiso esinamandla somsebenzi wokulinganisa ngokuchanekileyo.

Ixesha leposi: Juni-18-2025