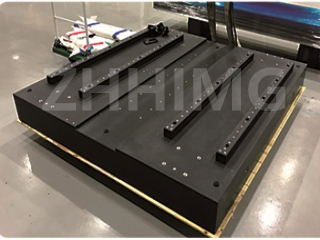

Kwishishini le-semiconductor, ukuhlolwa kwe-wafer likhonkco eliphambili lokuqinisekisa umgangatho kunye nokusebenza kwe-chip, kwaye ukuchaneka kunye nokuzinza kwetafile yokuhlolwa kudlala indima ebalulekileyo kwiziphumo zokufumanisa. Isiseko segranite esineempawu zaso ezizodwa, siba lukhetho olufanelekileyo kwitafile yokuhlolwa kwe-wafer ye-semiconductor, oku kulandelayo kuhlalutyo olunemilinganiselo emininzi kuwe.

Okokuqala, ubukhulu besiqinisekiso sokuchaneka

1. Ukuthe tye nokuthamba okuphezulu kakhulu: Isiseko segranite sicutshungulwa ngetekhnoloji yokucubungula ephucukileyo, kwaye ukuthe tye kunokufikelela kwi-±0.001mm/m okanye ukuchaneka okuphezulu, kwaye ukuthe tye nako kugqwesileyo. Kwinkqubo yokuhlola i-wafer, iplani echanekileyo kakhulu inika inkxaso ezinzileyo ye-wafer kwaye iqinisekisa ukudibana okuchanekileyo phakathi kweprobe yezixhobo zokuhlola kunye namalungu e-solder kumphezulu we-wafer.

2. I-coefficient ephantsi kakhulu yokwandiswa kobushushu: imveliso ye-semiconductor ivakalelwa kutshintsho lobushushu, kwaye i-coefficient yokwandiswa kobushushu be-granite iphantsi kakhulu, idla ngokuba malunga ne-5×10⁻⁶/℃. Xa iqonga lokufumanisa lisebenza, nokuba ubushushu obujikeleze umhlaba buyatshintshatshintsha, ubungakanani besiseko se-granite abutshintshi kangako. Umzekelo, kwindawo yokusebenzela yobushushu obuphezulu ehlotyeni, ubushushu beqonga lokufumanisa isiseko sesinyithi esiqhelekileyo bunokubangela ukuba indawo ehambelanayo ye-wafer kunye nezixhobo zokufumanisa zitshintshe, nto leyo echaphazela ukuchaneka kokufumanisa; Iqonga lokufumanisa isiseko se-granite linokugcina uzinzo, liqinisekise ukuchaneka kwendawo ehambelanayo ye-wafer kunye nezixhobo zokufumanisa ngexesha lenkqubo yokufumanisa, kwaye libonelele ngendawo ezinzileyo yokufumanisa ngokuchanekileyo okuphezulu.

Okwesibini, ubukhulu bozinzo

1. Isakhiwo esizinzileyo kunye nokumelana nokungcangcazela: I-Granite emva kwezigidi zeminyaka yeenkqubo zejoloji, isakhiwo sangaphakathi sixinene kwaye siyafana. Kwimeko enzima yefektri ye-semiconductor, ukungcangcazela okubangelwa kukusebenza kwezixhobo ezingaphandle kunye nabasebenzi abahambahambayo kuncitshiswa ngempumelelo yisiseko se-granite.

2. Ukuchaneka kokusetyenziswa kwexesha elide: xa kuthelekiswa nezinye izinto, i-granite inobunzima obuphezulu, ukumelana nokuguguleka okunamandla, kwaye ubunzima be-Mohs bunokufikelela kwi-6-7. Umphezulu wesiseko se-granite awuguguleki lula ngexesha lokulayisha rhoqo, ukukhupha nokuhlola i-wafer. Ngokweenkcukacha-manani zokusetyenziswa ngokuchanekileyo, ukusetyenziswa kwetafile yovavanyo lwesiseko se-granite, ukusebenza okuqhubekayo emva kweeyure ezingama-5000, ukuchaneka kokuthe tye kunye nokuthe tye kusenokugcinwa ngaphezulu kwe-98% yokuchaneka kokuqala, ukunciphisa izixhobo ngenxa yokuguguleka kwesiseko okubangelwa kukulinganisa rhoqo kunye namaxesha okugcina, ukunciphisa iindleko zokusebenza kweshishini, ukuqinisekisa uzinzo lwexesha elide lomsebenzi wovavanyo.

Okwesithathu, ubukhulu obucocekileyo nobuchasene nokuphazamiseka

1. Ukuveliswa kothuli oluphantsi: indawo yokuvelisa i-semiconductor kufuneka icoceke kakhulu, kwaye izinto zegranite ngokwazo zizinzile kwaye azilula ukuvelisa amasuntswana othuli. Ngexesha lokusebenza kweqonga lovavanyo, uthuli oluveliswa sisiseko luyathintelwa ukuze kungcoliswe i-wafer, kwaye umngcipheko we-short circuit kunye ne-open circuit ebangelwa ngamasuntswana othuli uyancitshiswa. Kwindawo yokuhlolwa kwe-wafer kwindawo yokusebenzela engenaluthuli, uxinano lothuli olujikeleze itafile yokuhlola isiseko segranite luhlala lulawulwa ukuya kwinqanaba eliphantsi kakhulu, luhlangabezana neemfuno zococeko ezingqongqo zeshishini le-semiconductor.

2. Akukho kuphazamiseka kwemagnethi: izixhobo zokufumanisa zinovakalelo kwindawo ye-electromagnetic, kwaye i-granite yinto engeyo-magnetic, engayi kuphazamisana nesignali ye-elektroniki yezixhobo zokufumanisa. Ekusetyenzisweni kokufumanisa imisebe ye-electron kunye nezinye iiteknoloji zokuvavanya ezifuna indawo ye-electromagnetic ephezulu kakhulu, isiseko se-granite siqinisekisa ukuhanjiswa okuzinzileyo kwesignali ye-elektroniki yezixhobo zokufumanisa kwaye siqinisekisa ukuchaneka kweziphumo zovavanyo. Umzekelo, xa i-wafer ivavanywa ukusebenza kombane okuchanekileyo, isiseko se-granite esingeyo-magnetic siphepha ukuphazamiseka kwimiqondiso yamandla okufumana kunye ne-voltage, ukuze idatha yokufumanisa ibonakalise ngokwenene iimpawu zombane ze-wafer.

Ixesha leposi: Matshi-31-2025