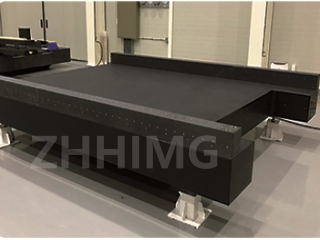

I-Granite luhlobo lwelitye eliyi-igneous elaziwa ngokuqina, ubulukhuni, kunye nokuzinza kwalo. Ezi mpawu zenza i-granite ibe yinto efanelekileyo kwiziseko zoomatshini kunye nokusetyenziswa ekucubungulweni kwe-wafer. Kweli nqaku, siza kuxoxa ngeenzuzo kunye nokungalungi kokusebenzisa iziseko zoomatshini be-granite ekucubungulweni kwe-wafer.

Iingenelo zeGranite Machine Base:

1. Uzinzo: I-Granite ine-coefficient ephantsi yokwandiswa kobushushu, oko kuthetha ukuba ihlala izinzile nokuba ibekwe kumaqondo obushushu aphezulu. Olu zinzo luqinisekisa ukuba isiseko somatshini sihlala sisendaweni yaso kwaye asishukumi ngexesha lokucubungula i-wafer.

2. Ukuqina: I-Granite yenye yezona zinto zinzima, nto leyo eyenza ukuba ingabi nakuguguleka. Olu kuqina luqinisekisa ukuba isiseko somatshini sinokumelana noxinzelelo kunye nokungcangcazela okuveliswa ngexesha lokucubungula i-wafer.

3. Ukungcangcazela okuphantsi: Ngenxa yokuzinza okungaphakathi kunye nobunzima begranite, ivelisa ukungcangcazela okuncinci ngexesha lokucubungula i-wafer. Oku kungcangcazela okuphantsi kunciphisa umngcipheko wokonakala kwe-wafer kwaye kuqinisekisa ukuchaneka nokuchaneka kokucubungula.

4. Ukuchaneka: Uzinzo oluphezulu kunye nokungcangcazela okuphantsi kwesiseko somatshini wegranite kuqinisekisa ukuchaneka ekucutshungulweni kwe-wafer. Oku kuchaneka kubalulekile ekudalweni kwee-semiconductors ezikumgangatho ophezulu, ezifuna ukuchaneka kwinkqubo yazo yokwenziwa.

5. Ukulula kokugcinwa: I-Granite yinto engenazimbobo, nto leyo eyenza kube lula ukuyicoca nokuyigcina icocekile. Oku kunciphisa ixesha kunye nomsebenzi ofunekayo wokugcinwa kwayo kwaye kwandisa ukusebenza kakuhle kwenkqubo yokucubungula i-wafer.

Izinto ezingalunganga kwiGranite Machine Base:

1. Ixabiso: Enye yezona zinto zingalunganga ngeziseko zoomatshini begranite kukuba zibiza kakhulu xa kuthelekiswa nezinye izinto. Oku kungenxa yobunzima kunye neendleko zokumba, ukuthutha, kunye nokubumba igranite.

2. Ubunzima: I-Granite yinto exineneyo, eyenza ibe nzima kwaye kube nzima ukuyihambisa. Oku kunokwenza kube nzima ukuyibeka kwakhona isiseko somatshini ngexesha lokufakelwa okanye ukulungiswa.

3. Ubunzima bokuSebenza ngomatshini: I-Granite yinto eqinileyo nerhabaxa, nto leyo eyenza kube nzima ukuyisebenza ngomatshini nokuyibumba. Oku kunokunyusa ixesha kunye neendleko ezifunekayo ukwenza isiseko somatshini.

Isiphelo:

Ukusetyenziswa kweziseko zomatshini wegranite ekucubungulweni kwe-wafer kunika iingenelo ezininzi, kubandakanya ukuzinza, ukuqina, ukungcangcazela okuphantsi, ukuchaneka, kunye nokulula kokugcinwa. Nangona kunjalo, ezi zibonelelo ziza ngexabiso eliphezulu kwaye zifuna izixhobo ezikhethekileyo kunye nobuchule bokwenza kunye nomatshini we-granite machine base. Nangona ezi ngxaki zingekho, iingenelo zeziseko zomatshini wegranite zenza ukuba zibe lukhetho oludumileyo kwimisebenzi yokucubungula i-wafer apho ukuchaneka kunye nokuchaneka kubaluleke kakhulu.

Ixesha lokuthumela: Novemba-07-2023