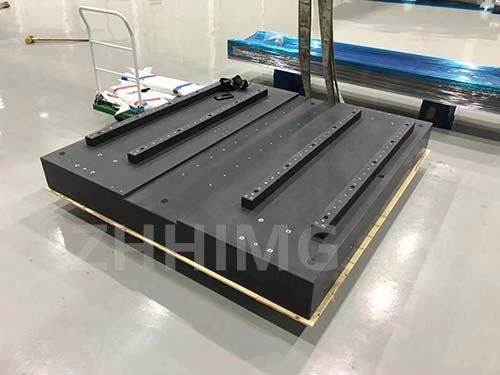

Iteknoloji yokwenza izinto ngokuzenzekelayo ibhekisa ekusetyenzisweni koomatshini kunye neekhompyutha ukwenza imisebenzi ebinokwenziwa ngesandla. Aba matshini benziwe ngamalungu ahlukeneyo, amanye awo anokwenziwa ngegranite. Igranite luhlobo lwelitye eliyi-igneous eliqinileyo kakhulu kwaye lihlala ixesha elide, okwenza libe yinto efanelekileyo kwiindawo zoomatshini. Kweli nqaku, siza kuxoxa ngeengenelo kunye nokungalungi kweendawo zoomatshini begranite kwiteknoloji yokwenza izinto ngokuzenzekelayo.

Iingenelo zeenxalenye zoomatshini beGranite

1. Ukuqina: Enye yezona nzuzo ziphambili zezixhobo zomatshini wegranite kukuqina kwazo. Igranite yinto eqinileyo kakhulu nehlala ixesha elide, nto leyo eyenza ukuba ilungele ukusetyenziswa kwiindawo zomatshini ezihlala zigugile. Iimatshini ezenziwe ngezixhobo zegranite zinokusebenza ixesha elide ngaphandle komonakalo omkhulu okanye ukuguguleka.

2. Ukumelana nokuguguleka: I-Granite yinto ekwaziyo ukumelana nokuguguleka. Iyakwazi ukumelana namanqanaba aphezulu oxinzelelo, ubushushu, kunye nokungcangcazela ngaphandle komonakalo. Oku kuyenza ibe lukhetho oluhle kakhulu kwiindawo zoomatshini ekufuneka zihlale zisetyenziswa, ezifana neebheringi, iigiya, kunye nezinye iindawo zoomatshini.

3. Umatshini wokulungisa izinto ngokuchanekileyo: I-Granite ikwayinto entle kakhulu yomatshini wokulungisa izinto ngokuchanekileyo. Ukufana kwezinto kwenze kube nokwenzeka ukuvelisa iindawo zomatshini ezichanekileyo kakhulu ezinokumelana okuqinileyo. Oku kubaluleke kakhulu kubuchwepheshe bokuzenzakalela, apho ukuchaneka kubaluleke kakhulu ekusebenzeni kakuhle koomatshini.

4. Ukumelana nokugqwala: I-Granite iyakwazi ukumelana nokugqwala, nto leyo eyenza ukuba ibe yinto efanelekileyo yoomatshini abadibana nezinto ezigqwala njengee-asidi kunye ne-alkali. Le propati ikwayenza ifaneleke ukusetyenziswa kumashishini afuna amanqanaba aphezulu ococeko, njengokulungisa ukutya kunye namayeza.

Iingxaki zeenxalenye zoomatshini beGranite

1. Ixabiso eliphezulu: Eyona ngxaki iphambili yezixhobo zomatshini zegranite yindleko yazo ephezulu. Igranite yinto ebiza kakhulu, kwaye iindleko zokwenza izixhobo zomatshini ngayo zinokuba phezulu kakhulu kunezinye izinto ezifana nentsimbi okanye i-aluminium.

2. Kunzima ukuyifaka ngomatshini: I-Granite yinto eqinileyo nerhabaxa, nto leyo eyenza kube nzima ukuyifaka ngomatshini. Oku kunokwenza inkqubo yokuvelisa ibe nzima kwaye ithathe ixesha elide, nto leyo enokubangela iindleko eziphezulu zemveliso.

3. Ubunzima obukhulu: I-Granite yinto exineneyo, kwaye iindawo zomatshini ezenziwe ngayo zinokuba nzima. Oku kunokuba yingxaki kwezinye izicelo apho iindawo zomatshini ezikhaphukhaphu zifuneka ukunciphisa ubunzima bomatshini ngokubanzi.

Isiphelo

Ukuqukumbela, iindawo zomatshini wegranite zineengenelo ezininzi ezenza zibe zizinto ezifanelekileyo kwitekhnoloji yokwenza izinto ngokuzenzekelayo. Ukuqina kwazo, ukumelana nokuguguleka, umatshini wokwenza izinto ngokuchanekileyo, kunye nokumelana nokugqwala kuzenza zibe lukhetho oluhle kakhulu kwiindawo zomatshini ekufuneka zihlale zisetyenziswa kunye neendawo ezinzima. Nangona kunjalo, iindleko eziphezulu, ubunzima bokwenza izinto ngokuzenzekelayo, kunye nobunzima obukhulu begranite bunokuba yingxaki kwezinye izicelo. Lilonke, iingenelo zeendawo zomatshini wegranite zingaphezulu kuneengxaki, kwaye zilukhetho oluhle kakhulu kwitekhnoloji yokwenza izinto ngokuzenzekelayo kumashishini amaninzi.

Ixesha leposi: Jan-08-2024