I-Granite lilitye lendalo elaziwa ngokuqina kwayo, amandla, kunye nokumelana nokuguguleka. Ngenxa yezi mpawu, lilitye elifanelekileyo lokusetyenziswa kwizixhobo zemveliso kwishishini le-semiconductor, njengezixhobo zokucubungula i-wafer. Kweli nqaku, siza kuhlola iingenelo ezininzi ezibonelelwa yi-granite kumxholo wemveliso yezixhobo zokucubungula i-wafer.

Okokuqala nokubalulekileyo, i-granite inomlinganiselo ophantsi kakhulu wokwanda kobushushu. Oku kuthetha ukuba ayikhuli okanye ayinciphisi kakhulu ngenxa yotshintsho kubushushu. Le yimpawu ebaluleke kakhulu kwizixhobo zokucubungula ii-wafer, ekufuneka zigcine ukunyamezelana okuchanekileyo ukuze zingalimazi ii-wafers ezithambileyo ezicutshungulwayo. Ukuba izixhobo zenziwe ngezinto ezinomlinganiselo ophezulu wokwanda kobushushu, notshintsho oluncinci kubushushu lunokubangela ukuba izixhobo zande okanye zinciphe, nto leyo ekhokelela ekungachanekini ekucutshungulweni kwee-wafers.

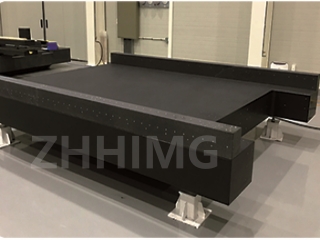

Enye inzuzo yegranite kukuzinza kwayo okuphezulu. Yinto eqinileyo neqinileyo kakhulu engagugiyo okanye ibole ngokuhamba kwexesha. Oku kuthetha ukuba izixhobo ezenziwe ngegranite zingasetyenziswa iminyaka emininzi ngaphandle kokufuna ukutshintshwa okanye ukulungiswa, nokuba zisetyenziswa kakhulu. Ukongeza, igranite inozinzo oluphezulu kakhulu, oko kuthetha ukuba inokugcina imo yayo kunye nobukhulu bayo ngokuhamba kwexesha nangona amaqondo obushushu okanye ukufuma etshintsha.

I-granite ikwamelana kakhulu nokugqwala kweekhemikhali, nto leyo eyenza ukuba ibe yinto efanelekileyo yokusetyenziswa kwiindawo ezinzima zeekhemikhali eziqhelekileyo ekucutshungulweni kwe-wafer. Uninzi lweekhemikhali ezisetyenziswa ekucutshungulweni kwe-wafer zinokuba ne-corrosive kakhulu kwiintsimbi nakwezinye izinto, nto leyo ekhokelela ekonakaleni okanye ekungasebenzi kakuhle kwezixhobo. Nangona kunjalo, i-granite ayichaphazeleki kakhulu zezi khemikhali, nto leyo eyivumela ukuba isebenze kakuhle kwaye igcine ulwakhiwo lwayo lusemgangathweni ngokuhamba kwexesha.

Ukongeza kwezi mpawu zisebenzayo, i-granite inezinye izibonelelo ezininzi xa isetyenziswa kwizixhobo zokucubungula i-wafer. Inembonakalo entle kakhulu, inepateni yengqolowa eyahlukileyo ethandekayo kwaye ikhethekile. Oku kunokuba yinto ebalulekileyo kwizixhobo zemveliso ye-semiconductor ephezulu apho ukubonakala kubalulekile. Ngaphezu koko, i-granite yinto yendalo ezinzileyo kwaye inobuhlobo nokusingqongileyo, nto leyo eyenza ukuba ibe lukhetho olunomtsalane kwiinkampani ezibeka phambili ukuzinza.

Ukuqukumbela, iingenelo zokusebenzisa i-granite kwimveliso yezixhobo zokucubungula i-wafer zininzi kwaye zibalulekile. Ukususela kwi-coefficient yayo ephantsi yokwandiswa kobushushu ukuya kumanqanaba aphezulu okuzinza kunye nokumelana nokugqwala kweekhemikhali, i-granite inika iseti ekhethekileyo yeempawu ezenza ukuba ibe yinto efanelekileyo kweli shishini. Ngenxa yoko, lukhetho olukhethwayo kubavelisi abaninzi be-semiconductor kwihlabathi liphela, kwaye kusenokwenzeka ukuba ihlale injalo kwixesha elizayo.

Ixesha leposi: Disemba-27-2023