Iziseko zoomatshini begranite ziye zathandwa kakhulu kwiminyaka yakutshanje ngenxa yeenzuzo zazo ezingokwemvelo ngaphezu kwezinto zemveli ezifana nesinyithi esityhidiweyo kunye nentsimbi. Kwicandelo lobuchwepheshe bokuzenzekela, iziseko zoomatshini begranite zibonelela ngeenzuzo ezininzi ezenza ukuba zibe lukhetho olukhethwayo kwimisebenzi emininzi yokuvelisa. Eli nqaku liza kuxoxa ngezinye zeenzuzo eziphambili zeziseko zoomatshini begranite kwaye lichaze ukuba kutheni zizinto ezifanelekileyo kwiimveliso zobuchwepheshe bokuzenzekela.

Okokuqala nokubalulekileyo, iziseko zoomatshini begranite zibonelela ngozinzo olungenakuthelekiswa nanto kunye nokunciphisa ukungcangcazela. Oku kubalulekile kwiteknoloji yokwenza izinto ngokuzenzekelayo, apho ukuchaneka nokuchaneka kubalulekile kwimpumelelo yomsebenzi. Igranite yinto egqwesileyo kakhulu yokwenza isinyithi okanye intsimbi xa kufikwa ekungcangcazeleni ukungcangcazela, njengoko inesantya esiphantsi kakhulu sendalo. Oku kuthetha ukuba nokunyakaza okuncinci kuyafunxwa kwaye akuphazamisi ukusebenza koomatshini. Ngesiseko somatshini wegranite, iinkqubo zokuvelisa zinokusebenza kakuhle, ngokuchanekileyo, nangokufanelekileyo.

Enye inzuzo yesiseko somatshini wegranite kukuxhathisa kwayo ukwanda kobushushu. Izinto zemveli ezifana nentsimbi ephosiweyo kunye nentsimbi zinomlinganiselo ophezulu wokwanda kobushushu, oko kuthetha ukuba zitshintsha imo kunye nobukhulu njengoko zichatshazelwa kutshintsho kubushushu. Oku kunokubangela ukungalungelelani kunye neminye imiba enokuchaphazela ukuchaneka kunye nokuchaneka koomatshini. Igranite, kwelinye icala, inomlinganiselo ophantsi kakhulu wokwanda kobushushu, okwenza ukuba izinze kwaye ithembeke ngakumbi. Oku kubaluleke kakhulu kubuchwepheshe bokuzenzekela, apho utshintsho lobushushu lunokuphazamisa ukusebenza koomatshini.

Iziseko zoomatshini begranite zikwabonelela ngokuqina nokuqina okugqwesileyo, nto leyo eyenza ukuba zibe zilungele iimveliso zobuchwepheshe bokuzenzekela ezifuna ukusetyenziswa rhoqo. Azikwazi ukuguguleka, kwaye zigcina imo yazo kunye nokugqitywa komphezulu wazo nasemva kweminyaka yokusetyenziswa kakhulu. Oku kuthetha ukuba zinciphisa iindleko zokulungisa kunye nobomi bezixhobo obude, nto leyo eyinzuzo ebalulekileyo kuyo nayiphi na imisebenzi yokuvelisa.

Enye inzuzo yeziseko zoomatshini begranite kukuzinza kwazo okuphezulu kobukhulu. Ngokungafaniyo nentsimbi ephothiweyo okanye intsimbi, enokugoba okanye iguqulwe ngokuhamba kwexesha, igranite igcina imo yayo kunye nozinzo lwayo lobukhulu naphantsi kweemeko ezinzima. Oku kubaluleke kakhulu kubuchwepheshe bokuzenzekela, apho ukunyamezelana okuchanekileyo kubalulekile kwimpumelelo yokusebenza. Ngesiseko somatshini wegranite, abavelisi banokuqiniseka ukuba izixhobo zabo ziya kugcina ukuchaneka kunye nokuhambelana kwazo ngokuhamba kwexesha.

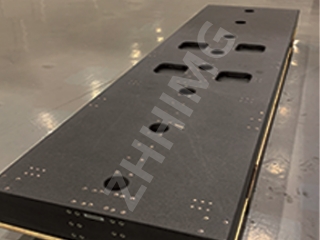

Okokugqibela, iziseko zoomatshini begranite zinika inkangeleko ekhangayo neyanamhlanje enokuphucula ubuhle bomgangatho wokwenziwa. Zihlala zigqityiwe zibe mhlophe, nto leyo enika inkangeleko entle neyobungcali. Oku kunokuba yinto ebalulekileyo kumashishini afuna ukubonisa umfanekiso wanamhlanje, osemgangathweni kubathengi bawo nakumaqabane awo.

Ukuqukumbela, iziseko zoomatshini begranite zibonelela ngeenzuzo ezininzi ezibalulekileyo ngaphezu kwezinto zemveli ezifana nesinyithi esityhidiweyo kunye nentsimbi. Uzinzo lwazo oluphezulu, ukuxinana kokungcangcazela, ukumelana nokwanda kobushushu, ukuqina, ukuqina, uzinzo olunemilinganiselo, kunye nenkangeleko zenza zibe lolona khetho lufanelekileyo kwiimveliso zobuchwepheshe bokuzenzekela. Nokuba uyila inkqubo entsha yokuvelisa okanye ujonge ukuphucula izixhobo zakho ezikhoyo, isiseko soomatshini begranite lutyalo-mali oluya kuhlawula ngokuchaneka okuphuculweyo, ukuchaneka, kunye nokuthembeka.

Ixesha leposi: Jan-03-2024