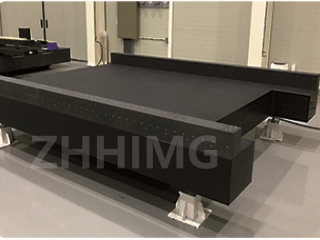

I-precision granite ibe yenye yezona zinto zibalulekileyo ezisetyenziswa kwimizi-mveliso ye-semiconductor kunye ne-solar. Iimpawu zayo ezikhethekileyo, ezinje ngokuzinza okuphezulu, ukuqina, kunye nokuchaneka, zenza ukuba ibe yinxalenye ebalulekileyo kubavelisi bezixhobo ze-semiconductor kunye ne-solar. Kweli nqaku, siza kuxoxa ngeenzuzo ze-precision granite kwimizi-mveliso ye-semiconductor kunye ne-solar.

Iingenelo zePrecision Granite kwiShishini leSemiconductor

1. Uzinzo oluPhezulu

I-precision granite izinzile kakhulu kwaye inokwanda okuphantsi kakhulu kobushushu, nto leyo ibalulekileyo kwishishini le-semiconductor. Ngokusebenzisa i-precision granite, abavelisi be-semiconductor banokunciphisa impembelelo yokuguquguquka kobushushu kwinkqubo yokuvelisa, beqinisekisa ukuba zonke iindawo zesixhobo se-semiconductor zilungelelaniswe ngokuchanekileyo.

2. Ukuqina

I-precision granite ikwahlala ixesha elide kakhulu, iyakwazi ukumelana nokuguga okunokubangelwa ziimeko ezinzima zokusebenza kwemveliso ye-semiconductor. Le nto ifanelekile ekwenzeni izixhobo ezichanekileyo kunye nezixhobo ezinokumelana nobunzima bemveliso ye-semiconductor.

3. Ukuchaneka Okuphezulu

I-precision granite inika ukuchaneka okuphezulu, okubalulekileyo ekuveliseni ii-semiconductor chips ezinezinga eliphezulu lokuchaneka. Le nto ivumela ukudalwa kwezixhobo zokulinganisa ezichanekileyo ezibalulekileyo ekulinganiseni nasekwenzeni izixhobo ze-semiconductor ngokuchanekileyo.

4. Kulula ukuyicoca nokuyigcina icocekile

Enye inzuzo yegranite echanekileyo kwishishini le-semiconductor kukuba kulula ukuyicoca nokuyigcina icocekile. Indlela igranite engenamibhobho ngayo yenza ukuba imelane namabala kunye nokugqwala, nto leyo ebaluleke kakhulu kwimveliso ye-semiconductor.

5. Ingenziwa ngokwezifiso

I-granite echanekileyo ikwanokulungiselelwa kakhulu, nto leyo evumela abavelisi be-semiconductor ukuba benze izixhobo ezihlangabezana neemfuno zabo ezithile. Abavelisi banokwenza i-granite ngokwezifiso ngokweemfuno zabo, kubandakanya ubungakanani, imilo, kunye nobume bomphezulu.

Iingenelo zePrecision Granite kwiShishini leSolar

1. Uzinzo oluPhezulu

Njengeshishini le-semiconductor, ishishini lelanga lifuna amanqanaba aphezulu ozinzo kwizixhobo zalo zokwenza. Ukwandiswa okuphantsi kobushushu be-precision granite kuyenza ilungele ukwenza izixhobo ezifunekayo ukwenza iiphaneli zelanga.

2. Ukuqina

Ukuqina kwe-precision granite kukwaluncedo kakhulu kwishishini lelanga. Iimeko ezinzima zokusebenza kwemveliso yeephaneli zelanga zifuna izixhobo ezinokumelana nobunzima bokusetyenziswa kwemihla ngemihla.

3. Ukuchaneka Okuphezulu

I-granite echanekileyo ibalulekile ekudaleni iiseli zelanga ngokuchanekileyo okuphezulu. Le nto isetyenziselwa ukwenza izixhobo zokulinganisa nokulungelelanisa ezifunekayo ukuqinisekisa ukuba iiseli zephaneli yelanga zilungelelaniswe ngokuchanekileyo.

4. Kulula ukuyicoca nokuyigcina icocekile

Indlela igranite engenamibhobho ngayo iyenza ifaneleke kakhulu ekwenzeni iiphaneli zelanga. Ayinazo iziphene kunye nokugqwala, nto leyo ebalulekileyo kwinkqubo yokwenza.

5. Ingenziwa ngokwezifiso

I-granite echanekileyo ikwanokulungiselelwa kakhulu, ivumela ukudalwa kwezixhobo zokwenza izinto zelanga ezilungiselelwe iimfuno ezithile. Abavelisi banokuyilungisa i-granite ukuze ihlangabezane neemfuno ezichanekileyo zenkqubo ethile yokuvelisa.

Isiphelo

Ukuqukumbela, i-precision granite yinto ebalulekileyo kumashishini e-semiconductor kunye ne-solar. Iimpawu zayo ezikhethekileyo, kubandakanya ukuzinza okuphezulu, ukuqina, ukuchaneka okuphezulu, ukugcinwa okulula, kunye nokwenza ngokwezifiso, zenza ukuba ifaneleke kakhulu kwizixhobo zokwenza. Ukusetyenziswa kwe-precision granite kuye kwavumela abavelisi kula mashishini ukuba bavelise izixhobo ezichanekileyo nezisemgangathweni, nto leyo ephucula umgangatho ngokubanzi wee-semiconductor chips kunye neepaneli zelanga. Ngenxa yoko, i-precision granite idlale indima ebalulekileyo ekuphuculeni itekhnoloji kunye nokudala ikamva lamandla elizinzileyo.

Ixesha leposi: Jan-11-2024