Kwishishini lezixhobo zokulawula amanani e-CNC, ukuchaneka, ukuzinza kunye nokuqina zizibonakaliso eziphambili zokulinganisa ukusebenza kwezixhobo. I-Granite, kunye neempawu zayo ezibalaseleyo zomzimba kunye neekhemikhali, ziye ngokuthe ngcembe zibe yinto ebalulekileyo ekuveliseni izixhobo ze-CNC kwaye zisetyenziswa ngokubanzi kwizixhobo ezahlukahlukeneyo eziphambili, ukufaka impembelelo entsha ekuphuhliseni ishishini.

I. Iimeko zeSicelo seGranite kwi-CNC yeSixhobo sokuLawula iinombolo

Isiseko seziko lomatshini oluchanekileyo oluphezulu

Kwimimandla efana nokulungiswa kokungunda okuchanekileyo kunye nokuveliswa kweendawo zomoya, iimfuno eziphezulu kakhulu zibekwe kwindawo echanekileyo kunye nokuphinda ukuchaneka kokumisa kumaziko omatshini. I-Granite, kunye nokuzinza kwayo okuhle kakhulu, isoloko isetyenziswa njengesiseko sezinto ezisisiseko kumaziko omatshini aphezulu. Isakhiwo sayo esixineneyo kunye nokuqina okuphezulu kunokuxhasa ngokufanelekileyo amacandelo angundoqo omatshini wesixhobo njenge-spindle kunye ne-rails yesikhokelo, ukunciphisa iimpazamo zokucubungula ezibangelwa ukuguqulwa kwesiseko. Ngokomzekelo, xa kusetyenzwa i-molds ye-injini ye-aero blades eneendawo ezinzima ezigobileyo, iziko lomatshini usebenzisa isiseko se-granite linokuqinisekisa ukuphunyezwa ngokuchanekileyo kwendlela yesixhobo kunye nokuphucula ukuchaneka kokubumba.

2. Iqonga lokulinganisa umatshini wokulinganisa ezintathu

Umatshini wokulinganisa ulungelelwaniso oluthathu sisixhobo esiphambili sokuhlolwa kwekhwalithi kwi-CNC machining, kwaye ukuchaneka kokulinganisa kwayo kuchaphazela ngokuthe ngqo umgangatho wemveliso. Iiplatifti zegranite, ezinomgangatho ophezulu kakhulu (ukuya kuthi ga ku-±0.1μm/m) kunye noburhabaxa obuphantsi kakhulu (Ra≤0.02μm), zibonelela ngomphezulu ozinzileyo wereferensi yokulinganisa iiprobe. Xa kuhlolwa imilinganiselo, imilo kunye nokunyamezela kweendawo ezichanekileyo, iiplatifomu zegranite ziyakwazi ukuphepha ngokufanelekileyo iimpazamo zokulinganisa ezibangelwa ukuguqulwa kwazo okanye iindawo ezingalinganiyo, ziqinisekisa ukuchaneka kunye nokuthembeka kwedatha yokuhlola.

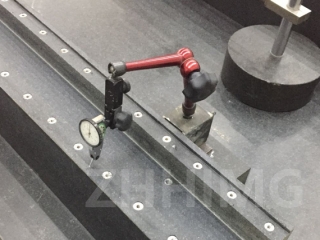

3. Isikhokelo somzila wezixhobo zomatshini we-CNC

Ukusebenza komzila wesikhokelo kumisela ukugudiswa kunye nokuchaneka kokuhamba kwesixhobo somatshini. Imizila yesikhokelo ye-Granite ibonakalisa i-coefficient ephantsi yokruthakruthwano kunye nokumelana okunamandla okunxiba. Xa kuthelekiswa neentsimbi zesikhokelo zentsimbi, zinokunciphisa ukunxiba kweendawo ezihambayo kunye nokunciphisa ukuphindaphinda kokugcinwa. Ngeli xesha, ukusebenza kwayo okugqwesileyo kokudambisa kunokufunxa ngokufanelekileyo ukungcangcazela ngexesha lokusebenza kwesixhobo somatshini kunye nokuphucula umgangatho womgangatho womatshini. Kwiinkqubo zokusika ngesantya esiphezulu, iileyili zesikhokelo segranite zinokugcina isixhobo sokusika kwisimo esizinzileyo sokusika, ukunciphisa uburhabaxa bomphezulu bomsebenzi, kunye nokuphucula ukusebenza kakuhle kunye nomgangatho wemveliso.

4. Ukukhutshwa kombane isixhobo somatshini wesixhobo sokusebenza

Ngexesha lenkqubo yokukhupha umbane, ubushushu obuphezulu kunye nokuphazamiseka kwe-electromagnetic kuyenziwa, nto leyo ebeka iimfuno eziphakamileyo kuzinzo kunye nokugquma kwetafile yokusebenza. I-Granite ayinayo kuphela ukuzinza kwe-thermal egqwesileyo, ekwaziyo ukumelana nokutshintsha kweqondo lokushisa ngexesha lokucubungula, kodwa ineempawu zendalo zokugquma kwaye azichatshazelwa kukuphazamiseka kwe-electromagnetic. Ngoko ke, iibhentshi ze-granite zinokubonelela ngendawo yokusebenza ezinzileyo yokukhutshwa kombane, ukuqinisekisa ukuchaneka kokucubungula kunye nomgangatho ophezulu.

Ii. Izinto eziluncedo ezingundoqo zeGranite kwi-CNC yesiXhobo sokuLawula amanani

Uzinzo olubalaseleyo lwe-thermal

Ngethuba lokuqhubeka kwexesha elide lokusebenza kwezixhobo ze-CNC, ubushushu obuninzi buyenziwa, obangela ukwanda kwe-thermal kunye nokunciphisa izixhobo zezixhobo. I-coefficient yokwandiswa kwe-thermal ye-granite iphantsi kakhulu (kuphela i-4-8 × 10⁻⁶/℃), kwaye ubukhulu bayo buhlala buhlala bungatshintshi xa ubushushu buguquka, obunokuphepha ngokufanelekileyo iimpazamo zokucubungula kunye nokuphambuka kokulinganisa okubangelwa yi-thermal deformation. Ngokomzekelo, kwiindawo ezinobushushu obuphezulu, izixhobo ze-CNC ezineziseko zegranite zisenokugcina ukuchaneka okuzinzile, ukuqinisekisa ukuba umgangatho wemveliso awuchaphazeli ukuguquka kweqondo lokushisa.

2. Ukusebenza okugqwesileyo kokuchasana nokungcangcazela

Ngexesha lenkqubo ye-CNC yomatshini, ukusebenza ngokukhawuleza kwesixhobo somatshini kunye namandla okusika kuya kubangela ukungcangcazela, okuchaphazela ukuchaneka komatshini kunye nomgangatho ophezulu. Ulwakhiwo olukhethekileyo lwekristale ngaphakathi kwegranite luyinika umsebenzi ogqwesileyo wokudambisa, isenza sikwazi ukuthomalalisa ngokukhawuleza amandla okungcangcazela kwangaphandle kunye nokunciphisa ukuphazamiseka kokungcangcazela. Idatha yovavanyo ibonisa ukuba umlinganiselo wokudambisa wegranite unokufikelela kwi-0.05-0.1, eyi-5-10 ngamaxesha ezinto zetsimbi. Inokunciphisa ngokufanelekileyo ukungcangcazela kwesixhobo kunye nokukhanya komphezulu womsebenzi, kwaye iphucule ukuchaneka kokusebenza kunye nokugqitywa komphezulu.

3. Ukuqina okuphezulu kunye nokumelana nokugqoka

IGranite inoxinano oluphezulu (ukuya kuthi ga kwi-2.6-3.0g/cm³) kunye nokuqina okukhulu (ngokuqina kwe-Mohs ye-6-7), kwaye ibonakalisa ubulukhuni obubalaseleyo kunye nokumelana nokunxiba. Xa iphantsi kwemithwalo enzima kunye nokuhamba rhoqo koomatshini bezixhobo ze-CNC, amacandelo e-granite awakwazi ukuguqulwa okanye ukunxiba kwaye anokugcina imeko echanekileyo ixesha elide. Ngokwezibalo, ixesha lokugcinwa ngokuchanekileyo kwezixhobo ze-CNC zisebenzisa amacandelo e-granite anokuba ngama-3 ukuya kwamaxesha ama-5 ubude kunezixhobo zetsimbi zendabuko, ukunciphisa kakhulu iindleko zokugcinwa kwezixhobo kunye nexesha lokuphumla.

4. Ukuzinza okuqinileyo kweekhemikhali

Kwinkqubo yomatshini we-CNC, ii-reagents zekhemikhali ezifana nokusika ulwelo kunye ne-lubricant zihlala zisetyenziswa, kwaye ezi zinto zinokubangela ukubola kumacandelo ezixhobo. I-Granite ineempawu zeekhemikhali ezizinzile, uluhlu olubanzi lwe-pH lokunyamezela (1-14), luyakwazi ukuxhathisa ukukhukuliseka kwezinto eziqhelekileyo zeekhemikhali, kwaye azikwazi ukugqwala okanye ukubola. Olu phawu alugcini nje ukwandisa ubomi benkonzo yamacandelo ezixhobo, kodwa luqinisekisa ukucoceka kwendawo yokucubungula, ukuphepha impembelelo kumgangatho wemveliso ngenxa yokungcola kweekhemikhali.

Ngokuchasene nemvelaphi ye-CNC yolawulo lwezixhobo zolawulo lwamanani oluqhubekayo lokuchaneka okuphezulu kunye nokusebenza okuphezulu, igranite, kunye neenzuzo zayo ezifana nokuzinza kwe-thermal, ukuxhathisa ukungcangcazela, ukuqina okuphezulu kunye nokuzinza kweekhemikhali, idlala indima engenakuphinda ithathelwe indawo kwiintlobo zezixhobo eziphambili. Ngokuqhubela phambili okuqhubekayo kwetekhnoloji, izixhobo zegranite ziya kusetyenziswa ngokubanzi kwibala le-CNC, ukukhuthaza ishishini ukuphuhlisa ukuchaneka okuphezulu kunye nomgangatho ophezulu..

Ixesha lokuposa: May-24-2025