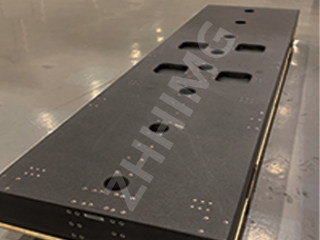

I-Granite lilitye lendalo elinozinzo oluhle kakhulu, ukwandiswa okuphantsi kobushushu, kunye nokuqina okuphezulu, okwenza ukuba ibe lukhetho oluthandwayo kwiintlobo ngeentlobo zezicelo zoshishino, kuquka iimveliso zokucubungula i-laser. Ngenxa yemfuno ekhulayo yoomatshini nezixhobo zoshishino ezichanekileyo, i-granite iye yaba yinto ethandwayo yokwakha iziseko zoomatshini ngokuchaneka okukhulu kunye nozinzo, nto leyo ebalulekileyo kwiimveliso zokucubungula i-laser. Nazi ezinye zeendawo zokusetyenziswa kwesiseko se-granite kwiimveliso zokucubungula i-laser:

1. Oomatshini bokusika ngeLaser

Ukuchaneka koomatshini bokusika nge-laser kubalulekile kwishishini lokuvelisa. I-Granite sisixhobo esifanelekileyo sesiseko sale mishini kuba ibonelela ngozinzo oluhle kakhulu lobushushu, oluvumela oomatshini ukuba bavelise ukusika okugudileyo nokuchanekileyo. I-coefficient yayo yokwandisa ubushushu ephantsi iqinisekisa ukuba isiseko somatshini asikhuli okanye sinciphe ngobushushu ngexesha lokusika nge-laser, okuqinisekisa umgangatho wokusika ohambelanayo kwizinto ezahlukeneyo.

2. Oomatshini bokuqopha ngeLaser

Oomatshini bokukrola nge-laser basetyenziselwa ukwenza uyilo oluchanekileyo kwiindawo eziqinileyo, ezifana nesinyithi, umthi, kunye negranite. Ukuchaneka okufunekayo kwezi matshini kwenza igranite ibe yinto esisiseko efanelekileyo njengoko iqinisekisa uzinzo kunye nokumelana nokungcangcazela. Ukuqina kwegranite kuqinisekisa ukuba isiseko somatshini asishukumi okanye singcangcazele ngexesha lokukrola, nto leyo ekhokelela kuyilo oluchanekileyo noluchanekileyo.

3. Oomatshini bokuMakisha ngeLaser

Oomatshini bokuphawula nge-laser basetyenziselwa ukongeza amabala angapheliyo kwiindawo ezahlukeneyo, kuquka iintsimbi, iiplastiki, kunye neeseramikhi. I-granite yinto ekhethwayo kwisiseko somatshini njengoko inika iipropati ezintle zokudambisa, inciphisa imiphumo yokungcangcazela kumatshini ngexesha lokusetyenziswa. Uzinzo lwe-granite luqinisekisa intshukumo encinci ngexesha lokuphawula, nto leyo ephumela kumabala achanekileyo nachanekileyo.

4. Oomatshini bokuWelda ngeLaser

Oomatshini bokuwelda nge-laser basetyenziselwa ukudibanisa izinto ezahlukeneyo, kuquka iintsimbi, iiplastiki, kunye neeseramikhi. Ukuchaneka okufunekayo kwezi matshini kwenza i-granite ibe yinto efanelekileyo yesiseko. Ukwanda kwayo okuphantsi kobushushu kunye nokuqina okuphezulu kuqinisekisa uzinzo kunye nokunyakaza okuncinci ngexesha lenkqubo yokuwelda, ukuqinisekisa ukuchaneka kunye nokuchaneka kwe-weld.

5. Oomatshini Bokugrumba Ngelaser

Oomatshini bokugrumba nge-laser basetyenziselwa ukwenza imingxunya echanekileyo kwiintlobo ezahlukeneyo zezinto, kuquka iintsimbi kunye neeseramikhi. Ukuchaneka okufunekayo kwezi matshini kwenza i-granite ibe yinto esisiseko efanelekileyo, inika uzinzo oluhle kakhulu kunye nomlinganiselo ophantsi wokwanda kobushushu. Oku kuqinisekisa ukugrumba ngokuchanekileyo ngaphandle kokuphazamiseka okanye umonakalo omkhulu kwizinto.

Ukuqukumbela, isiseko segranite sisixhobo esibalaseleyo sokwakha iziseko zoomatshini kwiimveliso zokucubungula i-laser ngenxa yokuzinza kwayo okuphezulu, ukuqina, kunye nomlinganiselo wokwanda kobushushu obuphantsi. Ukuchaneka okwandisiweyo kunye nokuchaneka kwezi matshini kubalulekile kwizicelo zokwenziwa kwemizi-mveliso, okwenza igranite ibe yinto efanelekileyo kwezi matshini. Ngenxa yoko, isiseko segranite siya kuqhubeka silukhetho oludumileyo kwiimveliso zokucubungula i-laser kwiimizi-mveliso ezahlukeneyo.

Ixesha lokuthumela: Novemba-10-2023