I-Granite lilitye lendalo elenziwe ngokuphola nokuqina kwe-volcanic magma okanye i-lava. Lilitye elixineneyo nelihlala ixesha elide elimelana kakhulu nokukrweleka, ukudaya, kunye nobushushu. I-Granite isetyenziswa kakhulu kwishishini lokwakha izinto zokwakha ezifana neekhawuntara, umgangatho, kunye neefacade ngenxa yokuqina kwayo kunye nokuqina kwayo. Ukongeza kwezi zicelo, i-granite ikwafumene indlela yayo kwishishini lezixhobo zokuhlanganisa ngokuchanekileyo, apho isetyenziswa kakhulu njengezinto ezisisiseko.

Izixhobo zokuhlanganisa ngokuchanekileyo zisetyenziswa kumashishini ahlukeneyo afana neemoto, i-aerospace, kunye nezonyango, apho imigangatho eqinileyo yokuchaneka nokuthembeka ibalulekile. Izinto ezisisiseko ziyafuneka kwezi zixhobo ezinokubonelela ngokudambisa ukungcangcazela okugqwesileyo, ukuqina okuphezulu, kunye nokuzinza kobushushu. I-Granite iyahlangabezana nazo zonke ezi mfuno, nto leyo eyenza ukuba ibe lolona khetho lufanelekileyo kwisiseko sezixhobo zokuhlanganisa ngokuchanekileyo.

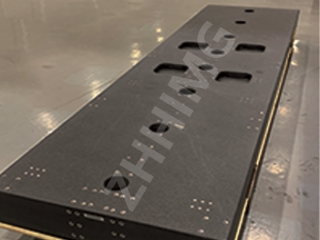

Enye yezona ndlela ziphambili zokusetyenziswa kwegranite kwizixhobo zokuhlanganisa ngokuchanekileyo kukuvelisa oomatshini bokulinganisa abalungelelanisiweyo (iiCMM). IiCMM zisetyenziswa kwizityalo zokwenza ukulinganisa ubukhulu bezinto ukuya kwinqanaba eliphezulu lokuchaneka. Aba matshini basebenzisa isiseko segranite kuba ibonelela ngeqonga elizinzileyo nelithembekileyo lenkqubo yokulinganisa. Igranite inomlinganiselo ophantsi kakhulu wokwandiswa kobushushu, oko kuthetha ukuba imelana kakhulu notshintsho kubushushu. Oku kuyenza ibe yinto efanelekileyo yokugcina ukuchaneka kwenkqubo yokulinganisa.

I-granite ikwasetyenziswa kakhulu ekuveliseni iinkqubo zokulungelelanisa i-optical. Ezi nkqubo zisetyenziselwa ukulungelelanisa izinto ezibonakalayo ukuya kwinqanaba eliphezulu kakhulu lokuchaneka. Izinto ezisisiseko se-granite zibalulekile kwezi nkqubo kuba zibonelela ngokuqina okuphezulu, okufunekayo ukugcina ukulungelelaniswa kwezinto ezibonakalayo. I-granite ikwamelana kakhulu nokungcangcazela, nto leyo eyenza ukuba ilungele ukusetyenziswa kwiindawo apho amanqanaba okungcangcazela aphezulu, njengezityalo zokwenza imveliso.

Enye indlela yokusebenzisa igranite kwizixhobo zokuhlanganisa ngokuchanekileyo kukuvelisa izixhobo zokwenza i-semiconductor. Ukuveliswa kwe-semiconductor kufuna izinga eliphezulu lokuchaneka ukuqinisekisa ukuba izixhobo zenziwe ngokwemigangatho echanekileyo. Isiseko segranite sibonelela ngozinzo nokuqina okufunekayo kwizixhobo zokwenza, okunceda ukuqinisekisa ukuba izixhobo zenziwe ngokweemfuno ezifunekayo.

Ukongeza kwezi zicelo, i-granite ikwasetyenziswa ekuveliseni izixhobo zelebhu, ezifana neebhalansi zokulinganisa kunye nezixhobo ze-spectroscopy. Ezi zixhobo zifuna uzinzo oluphezulu ukuqinisekisa ukulinganiswa okuchanekileyo. Isiseko se-granite sibonelela ngozinzo nokuqina okufunekayo kwezi ntlobo zezixhobo, nto leyo eyenza ukuba ibe lukhetho olufanelekileyo.

Ukuqukumbela, igranite yinto eguquguqukayo kakhulu esetyenziswa kakhulu kushishino lobunjineli bokuchaneka. Iimpawu zayo zokuqina okuphezulu, ukuxinana kokungcangcazela, kunye nokuzinza kobushushu zenza ukuba ibe lolona khetho lufanelekileyo kwizixhobo zokudibanisa ngokuchanekileyo. Ukusuka kwi-CMMs ukuya kwizixhobo zokwenza i-semiconductor, igranite ifumene indlela yayo kwiintlobo ngeentlobo zezicelo, inceda ukuqinisekisa ukuba izixhobo ezenziweyo zifikelela kwimigangatho echanekileyo yokuchaneka kunye nokuthembeka. Njengoko imfuno yezinto ezichaneke ngakumbi iqhubeka isanda, kusenokwenzeka ukuba ukusetyenziswa kwegranite kubunjineli bokuchaneka kuya kuqhubeka kukhula.

Ixesha lokuthumela: Novemba-21-2023