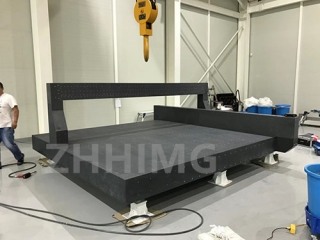

Ibhedi yomatshini wegranite isetyenziswa kakhulu kwiimveliso zeWafer Processing Equipment ngenxa yeempawu zayo ezintle. Igranite lilitye elivela ngokwemvelo elibizwa ngokuba liqinile, lilukhuni, kwaye liyamelana nokuguguleka. Ngenxa yoko, igranite ifunyenwe isetyenziswa kakhulu kwishishini lokuvelisa izinto njengezinto zokusebenzisa iibhedi zomatshini kwizicelo ezahlukeneyo, ingakumbi ezo zifuna umgangatho ophezulu wokuchaneka nokuzinza. Ezi zilandelayo zezinye zeendawo zokusetyenziswa kwebhedi yomatshini wegranite kwiimveliso zeWafer Processing Equipment:

1. Ukuveliswa kweeSemiconductor

Ukwenziwa kwee-semiconductor yenye yezona nkqubo zibalulekileyo nezintsonkothileyo kushishino lwe-elektroniki. Ukuveliswa kwee-wafers ezikumgangatho ophezulu kufuna ukusetyenziswa kwezixhobo ezichanekileyo kakhulu ezinokukwazi ukufikelela kumlinganiselo ongaphantsi kwe-micron enye. Ke ngoko, iibhedi zomatshini we-granite zisetyenziswa kwiimveliso ze-Wafer Processing Equipment ukuqinisekisa ukuba oomatshini bagcina ukuchaneka, uzinzo, kunye nokuphindaphindwa kwazo kwixesha elide lokusetyenziswa. Ngaphezu koko, iibhedi zomatshini we-granite zinokufunxa ukungcangcazela okuveliswa ngexesha lenkqubo yokwenziwa, ukunciphisa umngcipheko wokonakala kwee-wafers ezibuthathaka kunye nezinye izinto.

2. Ukuveliswa kwe-Optics

Ukwenziwa kwe-optical yenye indawo esetyenziswayo kwiibhedi zomatshini we-granite kwiimveliso ze-Wafer Processing Equipment. Iibhedi zomatshini we-granite zisetyenziswa ekuvelisweni kwezinto ezibonakalayo ezichanekileyo, ezifana neelensi, iiprism, izibuko, kunye nezihluzi, ezifuna inqanaba eliphezulu lokuzinza nokuchaneka ngexesha lenkqubo yokwenziwa. Iibhedi zomatshini we-granite zinokubonelela ngozinzo olufunekayo kunye nokuqina koomatshini, zithintele nayiphi na intshukumo engafunekiyo enokuchaphazela umgangatho wemveliso yokugqibela. Ngaphezu koko, iibhedi zomatshini we-granite zine-coefficient ephantsi yokwandiswa kobushushu, nto leyo eyenza zifaneleke ukusetyenziswa kwiindawo ezilawulwa bubushushu.

3. Ukuveliswa kwezixhobo zonyango

Ukwenziwa kwezixhobo zonyango yintsimi ekhethekileyo kakhulu efuna ukuchaneka nokuchaneka ekuvelisweni kwezinto ezahlukeneyo, ezinje ngee-implants, ii-prosthetics, kunye nezixhobo zotyando. Iibhedi zomatshini wegranite zisetyenziswa kwiimveliso zeWafer Processing Equipment ngexesha lokwenziwa kwezixhobo zonyango, ukuqinisekisa ukuba oomatshini banokugcina ukuchaneka nokuphindaphindwa kwazo ngokuhamba kwexesha. Ngaphezu koko, iibhedi zomatshini wegranite kulula ukuzicoca, okwenza kube lula ukugcina ucoceko kunye nokungabi nazintsholongwane okufunekayo ekwenzeni izixhobo zonyango.

4. Inqwelo-moya kunye noKhuselo

Amashishini eenqwelo moya kunye nokhuselo zezona zimbini zezona zinto zifunwa kakhulu kwiimveliso zeWafer Processing Equipment. La mashishini afuna ukuveliswa kwezinto ezinokumelana nobushushu obugqithisileyo, uxinzelelo, ukutshayiswa, kunye nokungcangcazela. Iibhedi zomatshini wegranite zisetyenziswa kwezi shishini ukubonelela ngeqonga elizinzileyo neliqinileyo loomatshini abenza izinto ezibalulekileyo, njengeenkqubo zokhokelo lwe-missile, iinjini zejethi, kunye nezinto zesathelayithi. Ngaphezu koko, iibhedi zomatshini wegranite ziyakwazi ukumelana neemeko zokusingqongileyo ezigqithisileyo kwaye zineempawu ezintle zokumelana nokutshayiswa, nto leyo eyenza ukuba zibe lukhetho olufanelekileyo kwizicelo zeenqwelo moya kunye nokhuselo.

Ukuqukumbela, iimveliso zeWafer Processing Equipment zidlala indima ebalulekileyo ekuvelisweni kwezinto ezahlukeneyo kumashishini ahlukeneyo. Iibhedi zomatshini wegranite zizinto ezibalulekileyo kwiimveliso zeWafer Processing Equipment, zibonelela ngozinzo olufunekayo, ukuchaneka, kunye nokuthembeka okufunekayo kwizicelo ezichanekileyo. Ngenxa yeempawu zazo ezintle, iibhedi zomatshini wegranite ziye zaba lukhetho oludumileyo kwizicelo kwimveliso ye-semiconductor, kwimveliso ye-optics, kwimveliso yezixhobo zonyango, nakwi-aerospace kunye nokhuselo.

Ixesha lokuthumela: Disemba-29-2023