Izixhobo zoomatshini begranite zibonakalise ukuba ziyinxalenye ebalulekileyo yezixhobo zokucubungula ngokuchanekileyo. Iimpawu zazo zokuqina okuphezulu, ukuzinza okuphezulu, ukwanda okuphantsi kobushushu, kunye nokumelana nokugqwala okugqwesileyo kuzenza zibe yeyona nto ibalulekileyo kwizicelo apho ukuchaneka nokuchaneka kubalulekile. Uluhlu olubanzi lwamashishini lusebenzisa izixhobo zoomatshini begranite, kubandakanya i-metrology, i-semiconductor manufacturing, izixhobo ze-optical, kunye ne-aerospace.

Kwizicelo zemetrology, ukulinganisa ngokuchanekileyo kubaluleke kakhulu, kwaye izinto zegranite mechanical zisebenza njengemigangatho efanelekileyo yesalathiso ngeenjongo zokulinganisa. Iingcali zemetrology zisebenzisa iipleyiti zegranite kunye neetyhubhu ukuseta iiplani zesalathiso kunye neendawo zesalathiso, ngokwahlukeneyo. Ezi zinto zibonelela ngomphezulu othe tyaba nozinzileyo wokulinganisa ngokuchanekileyo iimpawu ezincinci, ezinje ngobukhulu, ukuphakama, kunye nokuthamba. Uzinzo oluphezulu lweziqendu zegranite mechanical luqinisekisa ukuba ukuchaneka kwazo kuhlala kungaphazanyiswa ngokuhamba kwexesha, nto leyo eyenza ukuba zilungele ukusetyenziswa kwexesha elide kwimetrology.

Kwimveliso ye-semiconductor, ukuchaneka kunye nomgangatho weemveliso kubalulekile ekusebenzeni nasekuthembekeni kwazo. Izixhobo ze-granite ezifana nee-chucks, ii-wafer carriers, kunye nee-die pads zibonelela ngeqonga elizinzileyo nelilinganayo lokucubungula kunye nokuhlanganisa ii-wafers ze-semiconductor. Ukuqina okuphezulu kunye nokwanda okuphantsi kobushushu bezinto ze-granite kunceda ukunciphisa ukwenzeka kokugoba kunye nokuphazamiseka ngexesha lokucubungula, okubangela isivuno esingcono kunye neziphene ezimbalwa. Ukumelana nokugqwala okuhle kwe-granite kuqinisekisa ukuba ezi zinto zihlala zithembekile kwaye zomelele kwiindawo ezinobungcipheko beekhemikhali.

Kwizixhobo ze-optical, iimfuno zokuchaneka nokuchaneka ziphezulu ngokulinganayo. Izixhobo ze-granite zibonelela ngesiseko esizinzileyo nesingenangcangcazelo sophuhliso kunye nokulinganiswa kwezixhobo ze-optical ezifana neeteleskopu, ii-interferometers, kunye neenkqubo ze-laser. Ukwanda okuphantsi kobushushu bezixhobo ze-granite mechanical kunciphisa imiphumo yotshintsho lobushushu ekusebenzeni kwezixhobo ze-optical, okuphucula ukuchaneka kwazo kunye nokuthembeka kwazo. Ngaphezu koko, ukuqina okuphezulu kwezixhobo ze-granite kwenza kube lula ukwakhiwa kwezixhobo ze-optical ezinkulu nezinzima ngaphandle kokuphazamisa uzinzo lwazo.

Kwizicelo zeenqwelo-moya, ukusetyenziswa kwezinto ze-granite mechanical kuya kuthandwa kakhulu ngenxa yokukhanya kwazo, amandla aphezulu, kunye nokumelana nokonakaliswa kwendalo. Izinto ezidityanisiweyo ezisekelwe kwi-granite, ezifana ne-"Granitium," ziyazuza umdla njengezinto ezibalaseleyo zokwakha izinto ze-mechanical ngokuchanekileyo ezikhaphukhaphu kwiinqwelo-moya nakwiisathelayithi. Ezi zinto zibonelela ngeempawu ezibalaseleyo ze-mechanical kunye ne-thermal ezibalulekileyo ekusebenzeni kweenkqubo ngokuchanekileyo esibhakabhakeni nakwinqwelo-moya.

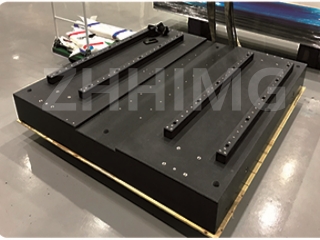

Ukuqukumbela, izinto ze-granite mechanical zidlala indima ebalulekileyo ekuphuhlisweni nasekusebenzeni kweemveliso zezixhobo zokucubungula ngokuchanekileyo kumashishini ahlukeneyo. Ukudibana kwazo okwahlukileyo kweempawu, kubandakanya ukuqina okuphezulu, ukwanda kobushushu obuphantsi, kunye nokuzinza okugqwesileyo kobukhulu, kuzenza zibe zibalulekile kwizicelo ezifuna ukulinganisa ngokuchanekileyo, ukucutshungulwa ngokuchanekileyo, kunye nokusebenza okuthembekileyo. Uhlobo oluguquguqukayo lwezinto ze-granite lukhokelele ekusetyenzisweni kwazo kuluhlu lwezixhobo, kubandakanya izixhobo ze-metrology, izixhobo ze-semiconductor, izixhobo ze-optical, kunye nezakhiwo ze-aerospace. Njengoko ubuchwepheshe buqhubeka, ukusetyenziswa kwezinto ze-granite mechanical kulindeleke ukuba kukhule, nto leyo ephucula ngakumbi ukuchaneka kunye nokuthembeka kweenkqubo zanamhlanje zoshishino.

Ixesha lokuthumela: Novemba-25-2023