Kwicandelo lokuvelisa ngokuchanekileyo, ingcamango ephosakeleyo eqhelekileyo kukuba "uxinano oluphezulu = ukuqina okunamandla = ukuchaneka okuphezulu". Isiseko segranite, esinoxinano lwe-2.6-2.8g/cm³ (7.86g/cm³ yesinyithi esityhidiweyo), sifikelele ekuchanekeni okungaphezulu kokwee-micrometers okanye ii-nanometers. Emva kwesi simo "esichasene nobuchule" kukho ukusebenzisana okunzulu kwe-mineralogy, mechanics kunye neendlela zokucubungula. Oku kulandelayo kuhlalutya imigaqo yayo yesayensi ukusuka kwiinkalo ezine eziphambili.

1. Uxinano ≠ Ukuqina: Indima ebalulekileyo yesakhiwo sezinto

Ulwakhiwo lwekristale "yehoneycomb yendalo" yegranite

I-Granite yenziwe ngeekristale zeminerali ezifana ne-quartz (SiO₂) kunye ne-feldspar (KAlSi₃O₈), ezidityaniswe kakhulu zii-ionic/covalent bonds, zenze isakhiwo esifana ne-honeycomb esidibeneyo. Esi sakhiwo siyinika iimpawu ezikhethekileyo:

Amandla okuxinwa ayafana nalawo esinyithi esityhidiweyo: afikelela kwi-100-200 mpa (100-250 mpa kwisinyithi esityhidiweyo esingwevu), kodwa i-elastic modulus iphantsi (70-100 gpa vs 160-200 gpa kwisinyithi esityhidiweyo), nto leyo ethetha ukuba akunakwenzeka ukuba iguqulwe iplastiki phantsi kwamandla.

Ukukhululwa kwendalo koxinzelelo lwangaphakathi: I-Granite iye yaluphala kwiminyaka engamakhulu ezigidi zeenkqubo zejoloji, kwaye uxinzelelo lwangaphakathi olusele lufikelela kwi-zero. Xa isinyithi esibunjiweyo sipholile (ngesantya sokupholisa esingaphezulu kwama-50℃/s), uxinzelelo lwangaphakathi olufikelela kuma-50-100 mpa luyaveliswa, ekufuneka lususwe ngokutsalwa kolwelo. Ukuba unyango aluphelelanga, lunokuguquguquka xa lusetyenziswa ixesha elide.

2. Ulwakhiwo lwesinyithi "esineziphene ezininzi" sesinyithi esityhidiweyo

Isinyithi esitshisiweyo sisixhobo esenziwe ngentsimbi-khabhoni, kwaye sineziphene ezifana ne-flake graphite, ii-pores kunye ne-shrinkage porosity ngaphakathi.

I-matrix yokuqhekeka kwe-Graphite: I-Flake graphite ilingana "ne-microcracks" yangaphakathi, nto leyo ebangela ukwehla kwe-30%-50% kwindawo yokuthwala umthwalo yesinyithi esityhidiweyo. Nangona amandla okuxinzelela ephezulu, amandla okugoba aphantsi (yi-1/5-1/10 kuphela yamandla okuxinzelela), kwaye ithambekele ekuqhekekeni ngenxa yoxinzelelo lwendawo.

Ubuninzi obuphezulu kodwa ubuninzi obungalinganiyo: Isinyithi esityhidiweyo siqulethe ikhabhoni eyi-2% ukuya kwi-4%. Ngexesha lokwenziwa, ukwahlulwahlulwa kwezinto zekhabhoni kunokubangela ukuguquguquka kobuninzi obuyi-±3%, ngelixa i-granite inomlinganiselo ofanayo wokusasazwa kwezimbiwa ongaphezulu kwe-95%, okuqinisekisa uzinzo kwisakhiwo.

Okwesibini, inzuzo yokuchaneka koxinano oluphantsi: ukuncitshiswa kabini kobushushu kunye nokungcangcazela

"Inzuzo yendalo" yolawulo lokuguqulwa kobushushu

I-coefficient yokwandiswa kobushushu iyahluka kakhulu: i-granite yi-0.6-5×10⁻⁶/℃, ngelixa i-cast iron iyi-10-12×10⁻⁶/℃. Thatha isiseko seemitha ezili-10 njengomzekelo. Xa ubushushu butshintsha nge-10℃:

Ukwandiswa kunye nokucutheka kwegranite: 0.06-0.5mm

Ukwandiswa kunye nokucutheka kwesinyithi esitshisiweyo: 1-1.2mm

Lo mahluko wenza i-granite iphantse ibe "yi-zero deformation" kwindawo elawulwa ngokuchanekileyo kubushushu (njenge-±0.5℃ kwindawo yokusebenzela ye-semiconductor), ngelixa isinyithi esityhidiweyo sifuna inkqubo eyongezelelweyo yokubuyisela ubushushu.

Umahluko wokuqhuba ubushushu: Ukuqhuba ubushushu begranite yi-2-3W/(m · K), eyi-1/20-1/30 kuphela yentsimbi ephosiweyo (50-80W/(m · K)). Kwiimeko zokufudumeza izixhobo (ezifana naxa ubushushu bemoto bufikelela kwi-60℃), i-gradient yobushushu bomphezulu wegranite ingaphantsi kwe-0.5℃/m, ngelixa eyentsimbi ephosiweyo inokufikelela kwi-5-8℃/m, nto leyo ebangela ukwanda okungalinganiyo kwendawo kwaye ichaphazele ukuthe tye kwereyile yesikhokelo.

2. Isiphumo "sokuthomalalisa kwendalo" sokuncitshiswa kokungcangcazela

Indlela yokusasaza amandla omda weenkozo zangaphakathi: Ukuqhekeka okuncinci kunye nokutyibilika komda weenkozo phakathi kweekristale zegranite kunokusasaza amandla okungcangcazela ngokukhawuleza, kunye nomlinganiselo wokudamba we-0.3-0.5 (ngelixa kwisinyithi esityhidiweyo yi-0.05-0.1 kuphela). Olu vavanyo lubonisa ukuba xa kungcangcazela i-100Hz:

Kuthatha imizuzwana eyi-0.1 ukuba ubukhulu begranite bubole bufikelele kwi-10%

Intsimbi ephosiweyo ithatha imizuzwana eyi-0.8

Lo mahluko uvumela i-granite ukuba izinze ngoko nangoko kwizixhobo ezihamba ngesantya esiphezulu (ezifana nokuskena kwentloko yokugquma nge-2m/s), kuthintelwe isiphene "seempawu zokungcangcazela".

Isiphumo esichaseneyo sobunzima be-inertial: Uxinano oluphantsi luthetha ukuba ubunzima buncinci kumthamo ofanayo, kwaye amandla e-inertial (F=ma) kunye nomfutho (p=mv) wenxalenye ehambayo aphantsi. Umzekelo, xa ifreyimu ye-granite gantry ye-10-meter (enobunzima beetoni ezili-12) ikhawuleziswa ukuya kwi-1.5G xa kuthelekiswa nefreyimu yesinyithi esityhidiweyo (iitoni ezingama-20), imfuneko yamandla okuqhuba iyancipha nge-40%, impembelelo yokuma kokuqala iyancipha, kwaye ukuchaneka kwendawo kuphucuka ngakumbi.

Iii. Inkqubela phambili kubuchwepheshe bokucubungula "obungenaxinano"

1. Ukuziqhelanisa nokucubungula ngokuchanekileyo kakhulu

Ulawulo "lwenqanaba lekristale" lokusila nokupolisha: Nangona ubunzima begranite (6-7 kwisikali seMohs) buphezulu kunobo besinyithi esityhidiweyo (4-5 kwisikali seMohs), isakhiwo sayo seminerali siyafana kwaye singasuswa ngeathom ngokusebenzisa i-diamond abrasive + magnetorheological polishing (ubukhulu be-single polishing < 10nm), kwaye uburhabaxa bomphezulu uRa bunokufikelela kwi-0.02μm (inqanaba lesipili). Nangona kunjalo, ngenxa yokubakho kwamasuntswana athambileyo egraphite kwisinyithi esityhidiweyo, "isiphumo se-furplough" sinokwenzeka ngexesha lokusila, kwaye uburhabaxa bomphezulu kunzima ukuba bube ngaphantsi kuneRa 0.8μm.

Inzuzo "yoxinzelelo oluphantsi" yomatshini wokugaya i-CNC: Xa kusetyenzwa i-granite, amandla okusika ayi-1/3 kuphela yalawo esinyithi esityhidiweyo (ngenxa yoxinano lwayo oluphantsi kunye ne-modulus encinci ye-elastic), evumela isantya esiphezulu sokujikeleza (ii-100,000 revolutions ngomzuzu) kunye namazinga okutya (5000mm/min), kunciphisa ukuguguleka kwezixhobo kunye nokuphucula ukusebenza kakuhle komatshini. Ityala elithile lomatshini we-five-axis libonisa ukuba ixesha lokucubungula i-granite guide rail grooves lifutshane ngama-25% kunelo lesinyithi esityhidiweyo, ngelixa ukuchaneka kuphuculwe ukuya kwi-±2μm.

2. Umahluko "kwisiphumo esiqokelelweyo" seempazamo zokuhlanganisa

I-chain reaction yobunzima becandelo elincitshisiweyo: Izinto ezifana neemoto kunye neereli zesikhokelo ezidityaniswe neziseko ezinoxinano oluphantsi zinokukhanyiswa ngaxeshanye. Umzekelo, xa amandla emoto ethe tyaba encitshiswa ngama-30%, ukuveliswa kobushushu kunye nokungcangcazela kwayo kuncipha ngokufanelekileyo, kwenze umjikelo omhle "wokuchaneka okuphuculweyo - ukusetyenziswa kwamandla okuncitshisiweyo".

Ukugcinwa ngokuchanekileyo kwexesha elide: Ukumelana nokugqwala kwegranite kuphindwe kalishumi elinesihlanu kunokwesinyithi esityhidiweyo (i-quartz iyamelana nokukhukuliseka kwe-asidi kunye ne-alkali). Kwimeko-bume ye-asidi ye-semiconductor, utshintsho loburhabaxa bomphezulu emva kweminyaka eli-10 yokusetyenziswa lungaphantsi kwe-0.02μm, ngelixa isinyithi esityhidiweyo kufuneka sicolwe kwaye silungiswe minyaka le, kunye nempazamo eqokelelweyo ye-±20μm.

Iv. Ubungqina Bemizi-mveliso: Umzekelo Obalaseleyo Woxinano Oluphantsi ≠ Ukusebenza Okuphantsi

Izixhobo zovavanyo lwe-semiconductor

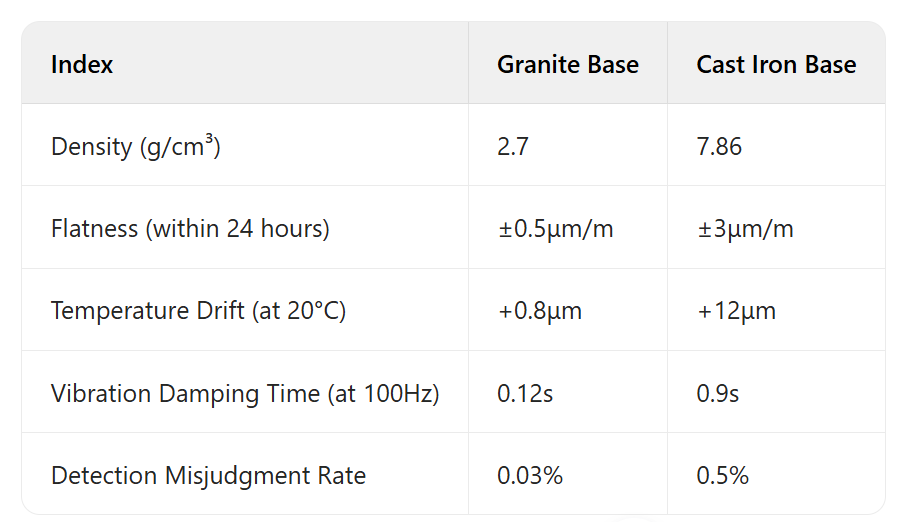

Idatha yokuthelekisa yeqonga elithile lokuhlola i-wafer:

2. Izixhobo ezibonakalayo ezichanekileyo

I-infrared detector bracket ye-NASA's James Webb Telescope yenziwe nge-granite. Kungokusebenzisa ngokunenzuzo uxinano lwayo oluphantsi (ukunciphisa umthwalo wesathelayithi) kunye nokwanda okuphantsi kobushushu (okuzinzileyo kumaqondo obushushu aphantsi kakhulu angama-270℃) apho ukuchaneka kokulungelelaniswa kwe-nano-level optical kuqinisekiswa, ngelixa umngcipheko we-cast iron ukuba buthathaka kumaqondo obushushu aphantsi ususwa.

Isiphelo: Ubuchule "bokuchasene nengqiqo eqhelekileyo" kwisayensi yezinto

Inzuzo yokuchaneka kweziseko zegranite ngokuyintloko ikukuphumelela kwengqiqo yezinto ezibonakalayo "ukufana kwesakhiwo > uxinano, ukuzinza kobushushu > ukuqina okulula". Ayiphelelanga nje ekubeni uxinano lwayo oluphantsi aluzange lube yindawo ebuthathaka, kodwa ikwafikelele kwinqanaba lokuchaneka ngeendlela ezifana nokunciphisa i-inertia, ukwenza ngcono ulawulo lobushushu, kunye nokuziqhelanisa nenkqubo yokucocwa ngokuchanekileyo. Le nto ityhila umthetho ophambili wokwenziwa ngokuchanekileyo: iipropati zezinto ezibonakalayo zilungelelaniso olupheleleyo lweeparameter ezininzi endaweni yokuqokelelwa okulula kwezibonisi ezizodwa. Ngophuhliso lwe-nanotechnology kunye nokuveliswa okuluhlaza, izixhobo zegranite ezinoxinano oluphantsi kunye nokusebenza okuphezulu zichaza ngokutsha imbono yemizi-mveliso "enzima" "nelula", "eqinileyo" kunye "neguquguqukayo", ivula iindlela ezintsha zokwenziwa okuphezulu.

Ixesha leposi: Meyi-19-2025