Njengoko iteknoloji yokusika i-laser ingena kwicandelo le-femtosecond kunye ne-picosecond lasers, iimfuno zokuzinza koomatshini bezixhobo ziye zaba zimbi kakhulu. Itafile yokusebenza, okanye isiseko somatshini, ayiseyiyo nje into yokuxhasa; yinto echaza ukuchaneka kwenkqubo. I-ZHONGHUI Group (ZHHIMG®) ihlalutya izizathu ezisisiseko zokuba kutheni i-granite enoxinano oluphezulu ibe lukhetho oluphezulu, olungaxoxiswana ngalo kunezixhobo zesinyithi zemveli zeetafile zokusebenza zokusika i-laser ezisebenza kakuhle.

1. Uzinzo lobushushu: Ukoyisa uMngeni wobushushu

Ukusika nge-laser, ngokwemvelo yako, kuvelisa ubushushu. Iitafile zokusebenza zesinyithi—ngokuqhelekileyo intsimbi okanye isinyithi esityhidiweyo—zinengxaki yokwanda kobushushu obuphezulu (CTE). Njengoko ubushushu butshintshatshintsha, isinyithi siyanda kwaye sinciphe kakhulu, nto leyo ekhokelela kutshintsho lobukhulu be-micron kumphezulu wetafile. Olu tshintsho lobushushu luguqulela ngokuthe ngqo kwiindlela zokusika ezingachanekanga, ingakumbi kwixesha elide okanye koomatshini abakhulu.

Ngokwahlukileyo koko, iBlack Granite yeZHHIMG® ine-CTE ephantsi kakhulu. Le nto ayimelani notshintsho lobushushu, iqinisekisa ukuba imilinganiselo ebalulekileyo yejometri yetafile yokusebenza ihlala izinzile nangona isebenza kakhulu kwaye ixesha elide. Le inertia yobushushu ibalulekile ekugcineni ukuchaneka kwenqanaba le-nanometer elifunekayo kwii-laser optics zanamhlanje.

2. Ukudambisa ukungcangcazela: Ukufikelela kuLawulo oluGqibeleleyo lweMisebe

Ukusika nge-laser, ingakumbi iinkqubo ze-laser ezikhawulezayo okanye ezishukumayo, kuvelisa amandla aguqukayo kunye nokungcangcazela. Isinyithi siyavakala, sikhulisa oku kungcangcazela kwaye sibangele ukungcangcazela okuncinci kwinkqubo, okunokufiphaza indawo ye-laser kwaye konakalise umgangatho wokunqunyulwa.

Ulwakhiwo lwegranite ephezulu ye-ZHHIMG® (ukuya kuthi ga kwi-≈3100 kg/m3) ifanelekile ngokukodwa kwi-vibration damping engcono kakhulu. Igranite ifunxa amandla oomatshini ngokwemvelo kwaye iwachithe ngokukhawuleza. Esi siseko sizolileyo nesizinzileyo siqinisekisa ukuba ii-optics ezigxile kwi-laser ezithambileyo kunye nee-motor ezikhawulezayo zisebenza kwindawo engena-vibration, zigcina ukuchaneka kokubekwa kwe-beam kunye nokuthembeka komphetho osikiweyo.

3. Ukunyaniseka kwezinto: Akungcolisi kwaye akungcolisi

Ngokungafaniyo nentsimbi, igranite ayibolisi. Ayinazo izinto ezipholisa umoya, ulwelo olusikiweyo, kunye nomswakama womoya oqhelekileyo kwiindawo zokwenza imveliso, nto leyo eqinisekisa ukuba itafile yokusebenza ihlala ixesha elide kwaye ukuthembeka kwayo kuhlala kuhleli ngaphandle komngcipheko wokugqwala okanye ukonakala kwezinto.

Ngaphezu koko, kwizixhobo ezidibanisa i-magnetic sensing ebukhali kakhulu okanye iteknoloji ye-linear motor, i-granite ayisebenzisi i-magnetic. Oku kususa umngcipheko wokuphazamiseka kwe-electromagnetic (EMI) onokuziswa ziziseko zesinyithi, okuvumela iinkqubo zokubeka ezintsonkothileyo ukuba zisebenze ngokungenasiphako.

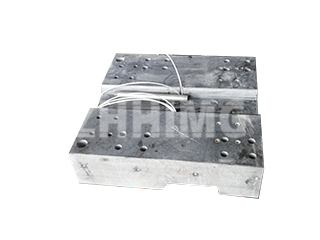

4. Amandla okucubungula: Ukwakha i-Big and Direct

Ubuchule bokuvelisa obungenakuthelekiswa nanto be-ZHHIMG® bususa imiqathango yobukhulu edla ngokuchaphazela iitafile ezisekwe kwisinyithi. Sigxile ekuveliseni iitafile zegranite ze-monolithic ezineqhekeza elinye ukuya kuthi ga kwiimitha ezingama-20 ubude kunye neetoni ezili-100 ubunzima, ezicociweyo ukuya kuthi ga kwi-nanometer flat yiingcibi zethu ezibalaseleyo. Oku kuvumela abakhi bomatshini be-laser ukuba benze izicucu zefomathi ezinkulu kakhulu ezigcina ukuthembeka kweqhekeza elinye kunye nokuchaneka okukhulu kuyo yonke i-envelope yabo yokusebenza—into engenakufikelelwa ziindibano zesinyithi ezidityanisiweyo okanye ezibotshiweyo.

Kubavelisi beenkqubo zokusika i-laser ezikumgangatho wehlabathi, ukhetho lucacile: uzinzo lobushushu olungenakuthelekiswa nanto, ukuxinana kokungcangcazela, kunye nokuchaneka kwe-monolithic ye-ZHHIMG® Granite Worktable kubonelela ngesiseko esiphezulu sesantya kunye nokuchaneka, ukuguqula imingeni ye-micron ibe yimiphumo eqhelekileyo.

Ixesha leposi: Okthobha-09-2025