Ukuthembeka kwayo nayiphi na inkqubo yokuvelisa ngokuchanekileyo okanye ye-metrology kuqala ngesiseko sayo. Kwi-ZHHIMG®, nangona udumo lwethu lwakhiwe kwizisombululo ze-Ultra-Precision Granite, siyayiqonda indima ebalulekileyo edlalwa ziiCast Iron Surface Plates kunye neeMarking Plates kumashishini ehlabathi. Ukuqonda indlela yokufaka, ukugcina, kunye nokuqinisekisa ukuchaneka kwezi zixhobo zesalathiso ngokufanelekileyo akusiyo nje indlela engcono yokwenza izinto—ngumahluko phakathi kokuqinisekiswa komgangatho kunye neenkunkuma ezibizayo.

Eyona mfuneko ipheleleyo: Ukufakelwa okufanelekileyo kunye nolwakhiwo olungagungqiyo

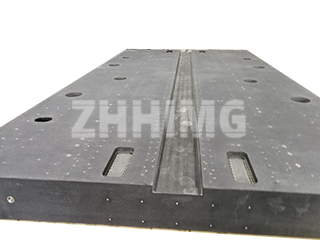

Ngaphambi kokuba ipleyiti yokumakisha yesinyithi esityhidiweyo ikwazi ukubonelela ngokuchanekileyo kwesalathiso sayo, kufuneka ifakwe kwaye ilungiswe ngokuchanekileyo. Eli nqanaba libalulekileyo lokuseta alikho nje ngokwenkqubo; lichaphazela ngokuthe ngqo ukuthembeka kwesakhiwo sepleyiti kunye nokuthamba kwayo. Ukufakelwa okungafanelekanga—njengokusasazwa komthwalo okungalinganiyo okanye ukulinganiswa okungafanelekanga—kunokwaphula imithetho yoshishino kwaye kutshintshe ipleyiti ngokusisigxina, okuyenza ingasetyenziswa. Ke ngoko, ngabasebenzi abagunyazisiweyo nabaqeqeshweyo kuphela abafanele benze lo msebenzi. Ukwaphula ezi nkqubo akupheleli nje ekungathobelini imithetho kodwa kunokubeka emngciphekweni ulwakhiwo lwesixhobo sokuchaneka.

Iipleyiti zokuMakisha kwindlela yokusebenza: Idatha yokuBhekisela

Kuyo nayiphi na indawo yokusebenzela, izixhobo zahlulwe ngokweendima ezithile: isalathiso, ukulinganisa, ukudweba ngokuthe ngqo, kunye nokubopha. Ipleyiti yokumakisha sisixhobo esibalulekileyo sesalathiso senkqubo yokubhala. Ukubhala ngokwako ngumsebenzi obalulekileyo wokuguqulela iinkcukacha zomzobo kwindawo yokusebenza engenanto okanye engagqitywanga ngokupheleleyo, ukumisela imida ecacileyo yokucubungula, amanqaku esalathiso, kunye nemigca ebalulekileyo yokulungisa. Oku kuchaneka kokuqala kokubhala, okuhlala kufuneka kube phakathi kwe-0.25 mm ukuya kwi-0.5 mm, kunempembelelo ethe ngqo nenzulu kumgangatho wemveliso yokugqibela.

Ukuze kugcinwe olu gqibelelo, ipleyiti kufuneka ilinganiswe kwaye ibekwe ngokukhuselekileyo, umthwalo usasazwe ngokulinganayo kuzo zonke iindawo zokuxhasa ukuthintela uxinzelelo lwesakhiwo. Abasebenzisi kufuneka baqinisekise ukuba ubunzima besixhobo somsebenzi abudluli umthwalo olinganisiweyo wepleyiti ukuthintela umonakalo wesakhiwo, ukuguquka, kunye nokwehla komgangatho womsebenzi. Ngaphezu koko, umphezulu wokusebenza kufuneka usetyenziswe ngokufanayo ukuthintela ukuguguleka nokuqhekeka kwendawo, ukuqinisekisa ukuhlala ixesha elide.

Ukuhlola i-Flatness: Isayensi yoQinisekiso

Indlela yokulinganisa yokwenyani yepleyiti yokubhala kukuba umphezulu wayo osebenzayo uthe tyaba kangakanani. Indlela ephambili yokuqinisekisa yiNdlela yeSpot. Le ndlela imisela uxinano olufunekayo lweendawo zoqhagamshelwano ngaphakathi kwendawo yesikwere engama-25mm:

- Iipleyiti zeBanga 0 kunye ne-1: Ubuncinane iindawo ezingama-25.

- Iipleyiti zeBanga lesi-2: Ubuncinane iindawo ezingama-20.

- Iipleyiti zeBanga lesi-3: Ubuncinane iindawo ezili-12.

Nangona indlela yendabuko "yokukrwela iipleyiti ezimbini ngokuchaseneyo" inokuqinisekisa ukulingana okuqinileyo kunye nokusondelana komphezulu, ayiqinisekisi ukuba zithe tyaba. Le ndlela inokubangela ukuba kubekho iindawo ezimbini ezihambelana ngokugqibeleleyo, eneneni, ezigobile ngokwesangqa. Ukuthe tye kwenene kunye nokuba tyaba kufuneka kuqinisekiswe kusetyenziswa iindlela ezingqongqo ngakumbi. Ukuphambuka kokuthe tye kunokulinganiswa ngokushukumisa isalathisi sedayali kunye nokuma kwayo kwinkxaso ecaleni kwesalathiso esithe tye esaziwayo, njengerula ye-engile echanekileyo, kumphezulu wepleyiti. Kwiipleyiti zokulinganisa ezifuna kakhulu, i-Optical Plane Method esebenzisa i-optical interferometry isetyenziswa ukuqinisekisa ukuchaneka kwinqanaba le-sub-micron.

Ukuphathwa Kweziphene Ngokufanelekileyo: Ukuqinisekisa Ukuphila Ixesha Elide Nokuthobela Imithetho

Umgangatho wepleyiti yokumakisha ulawulwa yimithetho engqongqo, efana nomgangatho we-JB/T 7974—2000 kushishino loomatshini. Ngexesha lenkqubo yokuphosa, iziphene ezifana nokuvuleka, imingxunya yesanti, kunye nemingxunya yokuncitshiswa zinokwenzeka. Ukuphathwa ngokufanelekileyo kwezi ziphene zokuphosa kubalulekile ebomini benkonzo yepleyiti. Kwiipleyiti ezinenqanaba lokuchaneka elingaphantsi kwe-“00,” ukulungiswa okuthile kuvumelekile:

- Iziphene ezincinci (amasuntswana esanti anobubanzi obungaphantsi kwe-15mm) zinokuxhonywa ngento efanayo, ukuba ubunzima beplagi buphantsi kunentsimbi ejikelezileyo.

- Umphezulu wokusebenza awufanele ube neendawo zokuxhuba ezingaphezu kwezine, ezahlulwe ngumgama we-$80\text{mm}$ ubuncinane.

Ngaphandle kokwenza iziphene, umphezulu wokusebenza mawungabi nagqwala, imikrwelo, okanye ukuqhekeka okuchaphazela ukusetyenziswa.

Ukugcinwa Kokuchaneka Okuhlala Kuhleli

Nokuba isixhobo sokubhekisa yiCast Iron Marking Plate okanye yiZHHIMG® Granite Surface Plate, ukugcinwa kwayo kulula kodwa kubalulekile. Umphezulu kufuneka ugcinwe ucocekile; xa ungasetyenziswa, kufuneka ucocwe kakuhle kwaye ugqunywe ngeoyile yokukhusela ukuthintela umhlwa kwaye ugqunywe ngesigqubuthelo sokukhusela. Ukusetyenziswa kufuneka kuhlale kusenziwa kwindawo elawulwayo, ngokufanelekileyo kubushushu obuphakathi obuyi-(20±5)℃, kwaye ukungcangcazela kufuneka kuthintelwe ngokungqongqo. Ngokulandela le migaqo ingqongqo yokufaka, ukusebenzisa, kunye nokugcinwa, abavelisi banokuqinisekisa ukuba iindlela zabo zokubhekisa zihlala zichanekile, zikhusela umgangatho kunye nokuthembeka kweemveliso zabo zokugqibela.

Ixesha leposi: Oktobha-31-2025