Kwicandelo lokwenziwa kwee-semiconductor, ukuchaneka kwezixhobo zokuhlola ii-wafer kumisela ngokuthe ngqo umgangatho kunye nemveliso yeetships. Njengesiseko esixhasa izinto ezisisiseko zokufumanisa, uzinzo olulinganayo lwezinto ezisisiseko sezixhobo ludlala indima ebalulekileyo ekusebenzeni kwexesha elide kwezixhobo. I-Granite kunye ne-cast iron zizinto ezimbini ezisisiseko ezisetyenziswa rhoqo kwizixhobo zokuhlola ii-wafer. Uphononongo lokuthelekisa lweminyaka eli-10 lutyhile umahluko omkhulu phakathi kwazo ngokubhekiselele kuzinzo olulinganayo, lubonelela ngeereferensi ezibalulekileyo zokukhetha izixhobo.

Imvelaphi yovavanyo kunye noyilo

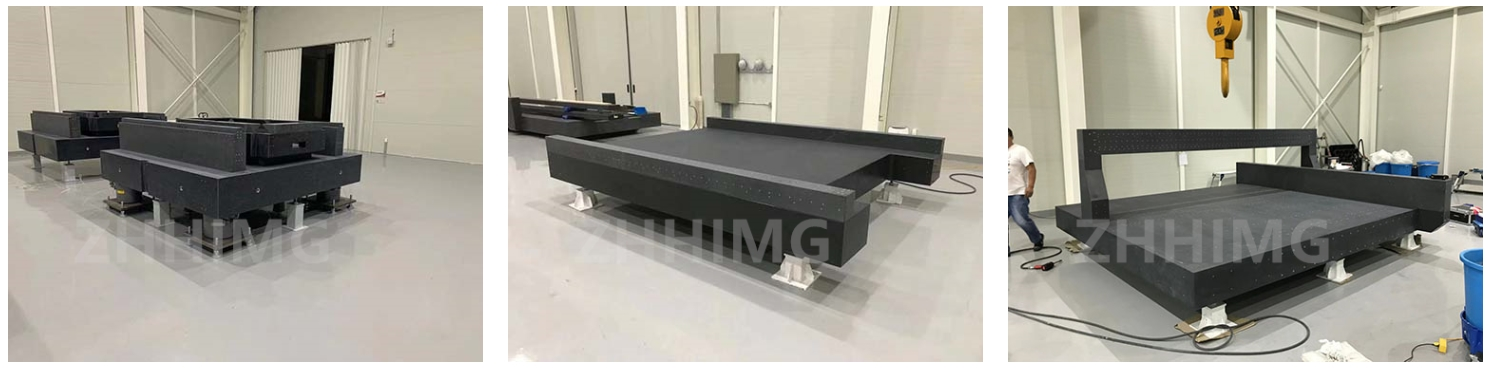

Inkqubo yokuvelisa ii-wafers ze-semiconductor ineemfuno eziphezulu kakhulu zokuchaneka kokufunyanwa. Nokuba ukuphambuka kobukhulu be-micrometer kunokukhokelela ekwehleni kokusebenza kwee-chip okanye ekukrazuleni. Ukuze kuhlolwe uzinzo olulinganayo lwe-granite kunye ne-cast iron ngexesha lokusetyenziswa ixesha elide, iqela lophando liyile iimvavanyo ezilinganisa iindawo zokusebenza zokwenyani. Iisampuli ze-granite kunye ne-cast iron zeenkcukacha ezifanayo zikhethiwe zaza zabekwa kwigumbi lokusingqongileyo apho ubushushu butshintsha ukusuka kwi-15℃ ukuya kwi-35℃ kwaye umswakama utshintsha ukusuka kwi-30% ukuya kwi-70% RH. Ukungcangcazela koomatshini ngexesha lokusebenza kwezixhobo kulinganiswe ngetafile yokungcangcazela. Ubukhulu obuphambili beesampuli bulinganiswa rhoqo ngekota kusetyenziswa i-interferometer ye-laser echanekileyo kakhulu, kwaye idatha irekhodwa rhoqo iminyaka eli-10.

Isiphumo sovavanyo: Inzuzo epheleleyo yegranite

Iminyaka elishumi yedatha yovavanyo ibonisa ukuba i-granite substrate ibonisa uzinzo olumangalisayo. I-coefficient yayo yokwandiswa kobushushu iphantsi kakhulu, i-avareji ye-4.6 × 10⁻⁶/℃ kuphela. Phantsi kotshintsho olukhulu lobushushu, ukuphambuka kobukhulu kuhlala kulawulwa ngaphakathi kwe-±0.001mm. Xa kujongwe utshintsho lomswakama, ulwakhiwo oluxineneyo lwegranite luyenza ingachaphazeleki phantse, kwaye akukho tshintsho lulinganisekayo lwebukhulu lwenzekayo. Kwimeko yokungcangcazela koomatshini, iimpawu ezintle zokudambisa zegranite zifunxa amandla okungcangcazela ngempumelelo, kwaye ukuguquguquka kobukhulu kuncinci kakhulu.

Ngokwahlukileyo koko, kwi-substrate yesinyithi esityhidiweyo, i-coefficient yayo ephakathi yokwandiswa kobushushu ifikelela kwi-11×10⁻⁶/℃ - 13×10⁻⁶/℃, kwaye ukuphambuka okuphezulu okubangelwa kukutshintsha kobushushu kwiminyaka eli-10 yi-±0.05mm. Kwimeko enomswakama, isinyithi esityhidiweyo sithambekele ekugqwaleni nasekuboleni. Ezinye iisampulu zibonisa ukuguguleka kwendawo, kwaye ukuphambuka kobukhulu kuyanda ngakumbi. Phantsi kwesenzo sokungcangcazela koomatshini, isinyithi esityhidiweyo sinomgangatho ophantsi wokudambisa ukungcangcazela kwaye ubungakanani baso buyatshintsha rhoqo, okwenza kube nzima ukuhlangabezana neemfuno ezichanekileyo zokuhlolwa kwe-wafer.

Isizathu esibalulekileyo somahluko kukuzinza

I-granite yadalwa kwiminyaka engamakhulu ezigidi ngeenkqubo zejoloji. Ulwakhiwo lwayo lwangaphakathi luxinene kwaye lufana, kwaye iikristale zeminerali zilungelelaniswe ngokuzinzileyo, zisusa uxinzelelo lwangaphakathi ngokwemvelo. Oku kuyenza ingabi namvakalelo kakhulu kutshintsho lwezinto zangaphandle ezifana nobushushu, ukufuma kunye nokungcangcazela. I-cast iron yenziwa ngenkqubo yokusika kwaye ineziphene ezincinci ezifana neembobo kunye nemingxuma yesanti ngaphakathi. Okwangoku, uxinzelelo olushiyekileyo oluvela ngexesha lenkqubo yokusika lunokubangela utshintsho kubukhulu phantsi kokukhuthazwa kwendalo yangaphandle. Iimpawu zesinyithi ze-cast iron zenza ukuba ithambekele ekugruleni ngenxa yokufuma, okukhawulezisa umonakalo wesakhiwo kunye nokunciphisa uzinzo lobukhulu.

Impembelelo kwizixhobo zokuhlola iiwafer

Izixhobo zokuhlola i-wafer ezisekelwe kwi-granite substrate, kunye nokusebenza kwayo okuzinzileyo, zinokuqinisekisa ukuba inkqubo yokuhlola igcina ukuchaneka okuphezulu ixesha elide, inciphise ukugwetywa gwenxa kunye nokubhaqwa okungaphoswanga okubangelwa kukushukuma kokuchaneka kwezixhobo, kwaye iphucule kakhulu isivuno semveliso. Okwangoku, iimfuno eziphantsi zolondolozo zinciphisa iindleko zomjikelo wobomi bonke bezixhobo. Izixhobo ezisebenzisa i-cast iron substrates, ngenxa yokuzinza okungalunganga kobukhulu, zifuna ukulinganiswa rhoqo kunye nokugcinwa. Oku akunyusi nje kuphela iindleko zokusebenza kodwa kunokuchaphazela umgangatho wemveliso ye-semiconductor ngenxa yokungachaneki ngokwaneleyo, okubangela ilahleko ezinokubakho kwezoqoqosho.

Phantsi kwendlela imboni ye-semiconductor elandela ngayo ukuchaneka okuphezulu kunye nomgangatho ongcono, ukukhetha i-granite njengesixhobo esisisiseko sezixhobo zokuhlola i-wafer ngokungathandabuzekiyo linyathelo lobulumko lokuqinisekisa ukusebenza kwezixhobo kunye nokuphucula ukukhuphisana kwamashishini.

Ixesha leposi: Meyi-14-2025