Izinto zegranite ezichanekileyo zizixhobo ezibalulekileyo kumashishini okuvelisa, okuhlola, kunye ne-metrology. Zibonelela ngomphezulu othe tyaba, ozinzileyo, nochanekileyo apho kunokuthathwa khona imilinganiselo. Igranite yinto efanelekileyo yezinto ezichanekileyo ngenxa yokuzinza kwayo, uxinano, kunye ne-coefficient ephantsi yokwandiswa kobushushu.

Kukho iintlobo ezahlukeneyo zezixhobo zegranite ezichanekileyo ezisetyenziswa kwizicelo ezahlukeneyo, kuxhomekeke kwiinkcukacha zazo kunye neemfuno zazo. Ezinye zezona ntlobo zixhaphakileyo zezixhobo zegranite ezichanekileyo zezi:

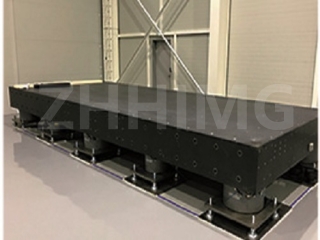

1. Iipleyiti Zomphezulu – Iipleyiti zomphezulu zinkulu, zithe tyaba ezenziwe ngegranite. Zihlala zifika ngobukhulu obuqala kwiisentimitha ezimbalwa ukuya kwiinyawo ezininzi ubude nobubanzi. Zisetyenziswa njengomphezulu obhekisayo wokuhlola, ukuvavanya, kunye nokulinganisa izixhobo ezahlukeneyo kunye neendawo. Iipleyiti zomphezulu zinokuba neendidi ezahlukeneyo zokuchaneka, ukusuka kwiBanga A, elilelona liphezulu, ukuya kwiBanga C, elilelona liphantsi.

2. Izikwere zeGranite – Izikwere zeGranite zizixhobo zokugaya ngokuchanekileyo kunye nokuhlola ezisetyenziselwa ukujonga ubume beendawo, kunye nokuseta oomatshini bokugaya kunye neegrinder zomphezulu. Ziza ngobukhulu obahlukeneyo, ukusuka kwisikwere esincinci se-2x2-intshi ukuya kwisikwere esikhulu se-6x6-intshi.

3. IiGranite Parallels – IiGranite parallels ziibhloko ezichanekileyo ezisetyenziselwa ukulungelelanisa izinto zokusebenza kumatshini wokusila, iilathes, kunye neegrinders. Zifumaneka ngobude nobubanzi obahlukeneyo, kwaye ukuphakama kuyafana kuzo zonke iibhloko ezikwiseti.

4. Iibhloko zeGranite V – Iibhloko zeGranite V zisetyenziselwa ukubamba izinto zokusebenza ezimile okwesilinda zokubhola okanye zokusila. Umngxuma onobume be-V kwiibhloko unceda ekubekeni phakathi izinto zokusebenza ukuze kwenziwe umatshini ochanekileyo.

5. Iipleyiti ze-Granite Angle – Iipleyiti ze-Granite angle zizixhobo ezichanekileyo ezisetyenziselwa uyilo, uhlolo, kunye nokulungiswa kweendawo. Zihlala zenziwe ngokweemfuno ezingqongqo, kunye nee-engile eziqala kwi-0 ukuya kwi-90 degrees.

6. Iibhloko zeGranite Riser – Iibhloko zeGranite riser zisetyenziselwa ukwandisa ubude beepleyiti zomphezulu, iipleyiti ze-engile, kunye nezinye izixhobo ezichanekileyo. Zisetyenziselwa ukuphakamisa izinto zokusebenza ziye kubude obufanelekileyo bokuhlolwa kunye noomatshini bokuchwetheza.

Ukongeza kwiintlobo ezahlukeneyo zezinto zegranite ezichanekileyo, kukwakho neenkcukacha ezahlukeneyo kunye namanqanaba asetyenziswa ukumisela ukuchaneka kunye nomgangatho wazo. Ukuchaneka kwento yegranite echanekileyo kudla ngokulinganiswa ngee-microns, eyiyunithi yokulinganisa elingana newaka leemilimitha.

Umgangatho wecandelo legranite elichanekileyo ubhekisa kwinqanaba lokuchaneka kwalo. Kukho amanqanaba aliqela ecandelo legranite elichanekileyo, apho iBakala A liphezulu kwaye iBakala C liphantsi. Umgangatho wecandelo legranite elichanekileyo umiselwa bubuthebelele balo, ukufana kunye nokugqitywa komphezulu.

Ukuqukumbela, izinto zegranite ezichanekileyo zizixhobo ezibalulekileyo kumashishini okuvelisa, okuhlola, kunye ne-metrology. Kukho iintlobo ezahlukeneyo zezinto zegranite ezichanekileyo ezisetyenziselwa usetyenziso olwahlukeneyo, kwaye ziza ngeenkcukacha ezahlukeneyo kunye namanqanaba ukuqinisekisa ukuba ziyahlangabezana neemfuno zokuchaneka, uzinzo, kunye nomgangatho weshishini.

Ixesha leposi: Februwari-23-2024