Kwicandelo lokuvelisa ngokuchanekileyo, izinto zegranite zimi njengeeqhawe ezingadunyiswanga ezixhasa ukuchaneka koomatshini abaphambili. Ukusuka kwimigca yemveliso ye-semiconductor ukuya kwiilebhu ze-metrology eziphambili, ezi zakhiwo zikhethekileyo zamatye zibonelela ngesiseko esizinzileyo esifunekayo sokulinganisa i-nanoscale kunye nemisebenzi echanekileyo. Kwi-ZHHIMG, sichithe amashumi eminyaka siphucula ubugcisa kunye nesayensi yoyilo lwezinto zegranite, sidibanisa ubugcisa bendabuko kunye nemigaqo yobunjineli yanamhlanje ukwenza izisombululo ezihlangabezana nemigangatho yemizi-mveliso enzima kakhulu.

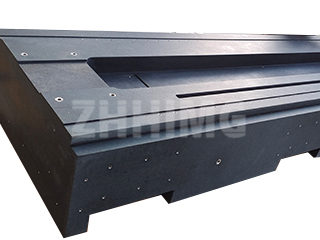

Uhambo lokwenza izinto zegranite ezichanekileyo nezisebenza kakuhle luqala ngokukhethwa kwezinto—isigqibo esibalulekileyo esichaphazela ngokuthe ngqo ukusebenza kwemveliso yokugqibela. Iinjineli zethu zisebenzisa i-ZHHIMG® black granite kuphela, izinto ezizimeleyo ezinobunzima obumalunga ne-3100 kg/m³ ezidlula iintlobo ezininzi zegranite zaseYurophu naseMelika zombini uzinzo kunye neempawu zomzimba. Esi sakhiwo sixineneyo asiboneleli nje kuphela ngokudambisa ukungcangcazela okungaqhelekanga kodwa siqinisekisa nokwandiswa okuncinci kobushushu, uphawu oluphambili lokugcina ukuchaneka kwiimeko ezahlukeneyo zendalo. Ngokungafaniyo nabanye abavelisi abasika iikona besebenzisa izinto ezithatha indawo zemabula, sihlala sizimisele kule nto ibalaseleyo eyenza umqolo wokuthembeka kwezixhobo zethu.

Nangona kunjalo, ukukhetha izinto kuphela yindawo yokuqala. Ubunzima bokwenyani boyilo lwe-granite bubonakala ekulinganiseni ngononophelo iimfuno zokusebenza kunye neenyani zokusingqongileyo. Uyilo ngalunye kufuneka luqwalasele ukusebenzisana phakathi kwe-component kunye nendawo yokusebenza kwayo, kubandakanya ukuguquguquka kobushushu, amanqanaba okufuma, kunye nemithombo yokungcangcazela enokubakho. I-workshop yethu yokulawula ubushushu kunye nokufuma eyi-10,000 m² (i-workshop yokulawula ubushushu kunye nokufuma rhoqo) yenzelwe ngokukodwa ukujongana nale mingeni, inemigangatho yekhonkrithi eqinileyo eyi-1000 mm ubukhulu kunye ne-500 mm ububanzi, imisele enzulu ye-2000 mm yokulwa nokungcangcazela edala imeko-bume efanelekileyo yokwenziwa kunye novavanyo.

Ukuchaneka koomatshini yenye isiseko soyilo olusebenzayo lwe-granite component. Ukuhlanganiswa kwezinto ezifakwa ngesinyithi kwi-granite kufuna ukunyamezelana okungqongqo ukuqinisekisa ukusasazwa komthwalo ngokufanelekileyo kunye nokudluliselwa kwe-torque. Iqela lethu loyilo liqwalasela ngononophelo ukuba ngaba izibophelelo zemveli zinokuthathelwa indawo ziinkqubo ezisekelwe kwi-groove ezichanekileyo, zihlala zivavanya urhwebo phakathi kobume besakhiwo kunye nokwenzeka kokuvelisa. Iimpawu zomphezulu zifuna ingqwalasela engqongqo—ukuthe tyaba kufuneka kugcinwe ngaphakathi kwamanqanaba e-micrometer, ngelixa iindawo ezithwala umoya zifuna iindlela ezikhethekileyo zokugqiba ukuze kufezekiswe ukuthamba okufunekayo ukuze kushukume ngaphandle kokungqubana.

Mhlawumbi okona kubaluleke kakhulu, uyilo lwe-granite yanamhlanje kufuneka lulindele iimfuno ezithile zesicelo sayo esicwangcisiweyo. Isiseko somatshini wokuhlola i-semiconductor, umzekelo, sijongene neemfuno ezahluke kakhulu kunepleyiti yomphezulu welebhu ye-metrology. Iinjineli zethu zisebenzisana ngokusondeleyo nabathengi ukuqonda kungekuphela nje iimfuno zobukhulu obukhawulezileyo kodwa kunye nolindelo lokusebenza kwexesha elide. Le ndlela yokusebenzisana ikhokelele kumacandelo asebenza indima ebalulekileyo kwizicelo eziqala kwiinkqubo ze-laser micromachining ukuya kumatshini okulinganisa adibeneyo aphambili (ii-CMM).

Inkqubo yokuvelisa ngokwayo imele ukudibana kobugcisa bendabuko kunye nobuchwepheshe obuphambili. Isakhiwo sethu sineemashini ezine zokugaya zaseTaiwan Nante, nganye idlula i-$500,000, ezikwaziyo ukucubungula izinto zokusebenza ukuya kuthi ga kwi-6000 mm ubude kunye nokuchaneka kwe-sub-micron. Kodwa ecaleni kwesi sixhobo siphambili, uza kufumana iingcali ezinamava angaphezu kwamashumi amathathu eminyaka ezinokufezekiswa kokuchaneka kwe-nanoscale ngokufaka isandla—isakhono esidla ngokusibiza ngokuba yi-“artisan metrology.” Olu dibaniso lwezinto ezindala nezintsha lusenza sikwazi ukujongana ne-geometries yezixhobo ezintsonkothileyo ngelixa sigcina imigangatho ephezulu yokuchaneka.

Ukuqinisekiswa komgangatho kugcwele kuwo onke amanqanaba oyilo lwethu kunye nenkqubo yokuvelisa. Sityale imali eninzi ekudaleni inkqubo yokulinganisa ebanzi equka iGerman Mahr Dial gauge (izalathisi zedayari) enesisombululo se-0.5 μm, iinkqubo zokulinganisa zeMitutoyo coordinate, kunye neRenishaw laser interferometers. Ngasinye kwezi zixhobo sivavanywa rhoqo yiJinan kunye neShandong Metrology Institutes, ukuqinisekisa ukulandeleka kwimigangatho yesizwe. Oku kuzibophelela ekugqweseni kokulinganisa kuhambelana nefilosofi yethu yenkampani: “Ukuba awukwazi ukuyilinganisa, awukwazi ukuyivelisa.”

Ukuzinikela kwethu ekuchaneni nasekusemgangathweni kusinike ubudlelwane neenkokheli zoshishino kwihlabathi liphela, kuquka i-GE, i-Samsung, kunye ne-Bosch, kunye namaziko ophando adumileyo afana ne-Singapore National University kunye ne-Stockholm University. Olu budlelwane luhlala lusishukumisela ukuba siphucule iindlela zethu zoyilo kwaye sihlole imida emitsha kwitekhnoloji ye-granite ye-ZHHIMG. Nokuba siphuhlisa inqanaba lokuthwala umoya elenziwe ngokwezifiso kumenzi we-semiconductor waseYurophu okanye ipleyiti yomphezulu ochanekileyo kwilebhu ye-metrology yaseMelika, imigaqo ephambili yesayensi yezinto eziphathekayo, ubunjineli boomatshini, kunye nolawulo lokusingqongileyo zihlala zizikhokelo zethu.

Njengoko imveliso iqhubeka nohambo lwayo olungapheliyo oluya kulungelelaniswa ngakumbi, indima yezinto zegranite ezichanekileyo iya kukhula ngokubaluleka. Ezi zakhiwo zimangalisayo zivala umsantsa phakathi kwehlabathi leemishini nezedijithali, zibonelela ngeqonga elizinzileyo apho ubuchwepheshe bethu obuphambili buxhomekeke khona. Kwi-ZHHIMG, siyazingca ngokuqhubekisela phambili ilifa lobugcisa begranite echanekileyo ngelixa samkela izinto ezintsha eziza kuchaza ikamva lokuvelisa. Iziqinisekiso zethu ze-ISO 9001, ISO 45001, ISO 14001, kunye ne-CE zimi njengobungqina bokuzibophelela kwethu kumgangatho, ukhuseleko, kunye noxanduva lokusingqongileyo—amaxabiso afakwe kuyo yonke into esiyila kwaye siyivelisa.

Ekugqibeleni, uyilo oluphumelelayo lwe-granite component alupheleli nje ekuhlangabezaneni nemimiselo; lumalunga nokuqonda injongo enzulu emva komlinganiselo ngamnye, ukunyamezelana ngakunye, kunye nokugqitywa komphezulu ngakunye. Lumalunga nokudala izisombululo ezivumela abathengi bethu ukuba batyhale imida yoko kunokwenzeka ekuvelisweni ngokuchanekileyo. Njengoko sijonge kwikamva, sihlala sizinikele ekuphuculeni isayensi yoyilo lwe-granite component, siqinisekisa ukuba ezi zinto zibalulekileyo ziyaqhubeka nokuxhasa izinto ezintsha zobuchwepheshe ezibumba ihlabathi lethu.

Ixesha lokuthumela: Novemba-03-2025