Izixhobo zoomatshini begranite zisetyenziswa kakhulu kwizixhobo zokucubungula ngokuchanekileyo ngenxa yozinzo lwazo oluphezulu, ukuqina, kunye nokwanda kwe-thermal coefficient ephantsi. Nangona kunjalo, ezi zixhobo zineemfuno ezithile kwindawo yokusebenza ukuze zigcine ukusebenza kwazo nokuqinisekisa ukuba azinakonakala ngokuhamba kwexesha. Kweli nqaku, siza kuqwalasela iimfuno zezixhobo zoomatshini begranite kwiimveliso zezixhobo zokucubungula ngokuchanekileyo kwindawo yokusebenza kunye nendlela yokugcina indawo yokusebenza.

1. Ubushushu

Izixhobo zoomatshini begranite ziyachaphazeleka kutshintsho lobushushu. Ubushushu obufanelekileyo bokusebenza kwezixhobo zegranite yi-20-25°C. Ukuba ubushushu buphezulu kakhulu okanye buphantsi kakhulu, bunokubangela utshintsho kubungakanani bezixhobo zegranite. Ke ngoko, kuyimfuneko ukuqinisekisa ubushushu obungaguqukiyo kwindawo yokusebenza ngokusebenzisa iinkqubo zomoya opholileyo okanye zokufudumeza. Ubushushu kufuneka bugcinwe ngaphakathi kobubanzi be-18-26°C ukuqinisekisa umlinganiselo ochanekileyo nozinzileyo.

2. Ukufuma

Izinto zegranite nazo zinobuthathaka kumswakama kunye nokufuma. Amanqanaba aphezulu okufuma anokubangela ukubola kunye nokuguguleka, okunokuchaphazela ukuchaneka kokulinganisa. Ke ngoko, indawo yokusebenza kufuneka igcinwe kwinqanaba lokufuma elingama-40-60%. Oku kunokufezekiswa ngokusebenzisa izixhobo zokususa umswakama okanye ngokuqinisekisa ukuba umoya ungena kakuhle.

3. Ukungcangcazela

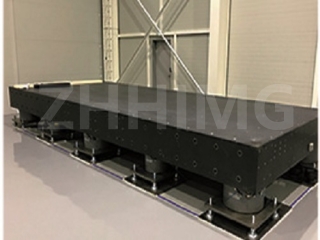

Ukungcangcazela kunokubangela ukuba izinto zegranite ziguge kwaye zilahlekelwe kukuchaneka kwazo. Ngenxa yoko, kubalulekile ukunqanda imithombo yokungcangcazela kwindawo yokusebenza. Oku kunokufezekiswa ngokwahlula umatshini okanye izixhobo apho izinto zifakelwe khona kwindawo engqongileyo. Kukwacetyiswa ukuba kusetyenziswe izinto ezifunxa ukubetheka ukuze kuncitshiswe imiphumo yokungcangcazela.

4. Uthuli kunye nenkunkuma

Izinto zegranite zichaphazeleka lula luthuli kunye nenkunkuma. Uthuli kunye nenkunkuma zinokubangela ukuguguleka, nto leyo ekhokelela kwiimpazamo ekulinganisweni nasekuchanekeni. Ngoko ke, kuyimfuneko ukugcina indawo yokusebenza icocekile ingenaluthuli kunye nenkunkuma. Oku kunokufezekiswa ngokucoca rhoqo kunye nokucoca indawo yokusebenza.

5. Ukugcinwa

Ukugcinwa rhoqo kwezinto zegranite kubalulekile ukuqinisekisa ukuba zihlala ixesha elide kwaye zichanekile. Izinto kufuneka zihlolwe rhoqo ukuze zibonakale ukuba zigugile okanye azigugi. Naziphi na iimpawu zokugugika kufuneka zilungiswe ngoko nangoko. Kwakhona, kufuneka kwenziwe uhlengahlengiso oluqhelekileyo lwezixhobo ukuqinisekisa ukuchaneka kwazo.

Ukuqukumbela, izinto zoomatshini zegranite zidlala indima ebalulekileyo ekucubunguleni iimveliso zezixhobo ngokuchanekileyo. Ukuqinisekisa ukuba ezi zinto zisebenza kakuhle, kuyimfuneko ukugcina indawo yokusebenza elawulwayo necocekileyo. Ukugcina ubushushu obungaguqukiyo, ukufuma, kunye nokuphepha ukungcangcazela kubalulekile ukuze kulinganiswe ngokuchanekileyo. Uthuli kunye nenkunkuma kufuneka kugcinwe ubuncinci, kwaye ukugcinwa rhoqo kwezinto kuyimfuneko. Ngokulandela le migaqo, ixesha lobomi bezinto zegranite liya kwandiswa, kwaye iimveliso zezixhobo zokucubungula ngokuchanekileyo ziya kuhlala zichanekile kwaye zithembekile.

Ixesha lokuthumela: Novemba-25-2023