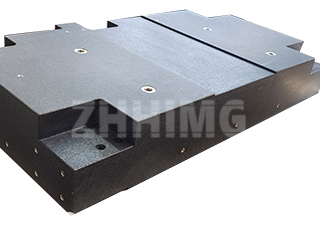

Indima yeGranite Core

Umqadi onqamlezileyo wegranite ungaphezulu kakhulu kunento elula yokwakha; sisixhobo sokubhekisa ngokuchanekileyo—umqolo oqinisekisiweyo wayo nayiphi na inkqubo ye-metrology okanye ye-machining ephucukileyo. Kwiindibano ezisusela kwii-gantry cutters ukuya kwii-complex coordinate measuring machines (CMMs), igranite isebenza njengebhentshi yokusebenza ethe tyaba, engaguqukiyo efunekayo ekubhaleni, ekulinganiseni, nasekudibaniseni iintshukumo ezintsonkothileyo ze-mechanical.

Ukuzinza okungokwemvelo kwegranite—ukuxhathisa kwayo umhlwa, i-asidi, imagnetism, kunye nokutshintsha kobushushu—kuvumela iingcali ukuba zigxile kuphela ekuchanekeni kweendawo ezihambayo ezifakelwayo. Xa wakha phezu komqadi wegranite we-ZHHIMG®, wakha phezu komqadi ogqibeleleyo. Nangona kunjalo, kwanendawo egqibeleleyo ifuna ukwenziwa ngononophelo ngexesha lokuhlanganiswa kwecandelo.

Isiseko seNdibano Engenasiphako

Ukuze umatshini wokugqibela ufezekise kwaye ugcine ukuchaneka kwawo okufunekayo, yonke into eqhotyoshelwe kumqadi onqamlezileyo wegranite kufuneka ilandele imigangatho engqongqo yomgangatho kunye nokulungiswa. Kulapho ukuhlanganiswa koomatshini kutshintsha khona ukusuka kubugcisa ukuya kwisayensi:

1. Ukulungiselela: I-Slate Ecocekileyo Kakhulu

Ngaphambi kokuba kubekho ukudibana, yonke into kufuneka icoceke ngokupheleleyo. Oku akupheleli nje ekubonakaleni; kukwamalunga nokususa izinto ezincinci ezitshabalalisa ukuchaneka. Zonke izinto eziseleyo zesanti, umhlwa, kunye nenkunkuma kufuneka zisuswe ngononophelo. Kwiindawo ezinzima ezifana nemingxuma yangaphakathi okanye izinto zegantry, ukufaka ipeyinti engaphakathi yepeyinti yokulwa nomhlwa emva kokucoca linyathelo elibalulekileyo. Idizili, iparafini, okanye ipetroli zihlala zisetyenziswa njengolwelo lokucoca ukunyibilikisa ioyile kunye negrisi, kulandele ukomiswa kakuhle ngomoya ocinezelweyo ukuthintela nayiphi na intsalela ukuba ingangeni emngciphekweni.

2. Ukunyaniseka kunye nokulingana ngokwemilinganiselo

Umgaqo oyintloko wokuhlanganisa ngokuchanekileyo ulula: ubukhulu kufuneka bube ngokuchanekileyo. Ngexesha lokuhlanganiswa kwi-crossbeam ye-granite, iingcali kufuneka ziphinde zijonge—okanye ubuncinane, zenze uhlolo olungacwangciswanga—lwazo zonke iimilinganiselo ezibalulekileyo zokudibana. Oku kuquka umgama ochanekileyo phakathi, ukulingana phakathi kweejenali eziphambili kunye neebheringi, kunye nokunyamezelana kwemingxunya yokufaka iibheringi. Nakuphi na ukuphambuka apha kuya kuguqulela ngqo ekuphumeni, ukungcangcazela, okanye ubomi bomatshini obuncitshisiweyo. Ngaphezu koko, iindawo ezidibeneyo kufuneka zibe bushelelezi kwaye zithe tyaba. Naziphi na ii-burrs okanye ii-deformations kufuneka zinqunyulwe ukuqinisekisa ukuba izinto zifikelela kunxibelelwano olupheleleyo, oluqinileyo kumphezulu wereferensi ye-granite ngaphandle kokujika okanye izithuba.

3. Ukuthambisa kunye nokutywina: Ukukhusela iNtshukumo

Ukuqinisekisa ukuba izinto zoomatshini zihamba kakuhle kwaye zimelana nokuguguleka, ukuthambisa nokutywina ngokufanelekileyo akunakuxoxiswana ngako. Imiphezulu yokudibana, ingakumbi ngaphakathi kweendibano zeebheringi kwibhokisi yespindle okanye iinuts zesixhobo sokuphakamisa, kufuneka ithanjiswe kwangaphambili ngaphambi kokuba iqhagamshelwe.

Izitywino, ezifana nee-O-rings, kufuneka ziphathwe ngononophelo olukhulu. Kufuneka zicinezelwe ngaxeshanye kwimiqolo yazo, ngaphandle kokujijeka okanye ukuguquguquka, kwaye umphezulu wokutywina mawungabi namonakalo okanye imikrwelo. Isitywino esichaphazelekileyo sibiza ungcoliseko, oluyingxaki yokuchaneka.

4. Ukuchaneka koMjikelezo ojikelezayo noweMigca

Iindibano ezibandakanya ukuhanjiswa kwamandla, njengeevili, izixhobo, okanye iinkqubo ze-pulley, zinemida eyongezelelweyo yejometri.

Kwindibano yegiya, ii-axes zeegiya ezimbini kufuneka zihambelane ngokugqibeleleyo kwaye zihambelane, ziqinisekisa ukuba izinyo libuyela umva ngendlela efanelekileyo nefanayo. Ngokufanayo, kwindibano ye-pulley, ii-axes kufuneka zihambelane, kwaye amaziko e-groove kufuneka ahambelane ngokugqibeleleyo. Ukuphambuka okukhulu kwe-axial okanye ukungalungelelani kuya kubangela uxinzelelo olungalinganiyo, okukhokelela ekutyibilikeni kwebhanti, ukungcangcazela okugqithisileyo, kunye nokuguguleka ngokukhawuleza—konke oku kuya kuyiphazamisa uzinzo olubonelelwa sisiseko se-granite. Ukukhetha iseti ye-V-belt ehambelanayo ngaphambi kokufakwa kubalulekile ukuthintela ukungcangcazela ngexesha lokudluliselwa kwamandla.

5. Ukufakwa kweeBheri: Eyona ndawo ichanekileyo kakhulu

Ukuhlanganiswa kweebheringi kufuna unonophelo oluphezulu. Emva kokususa ipeyinti yokulwa nomhlwa kunye nokucoca kakuhle ibheringi, iingcali kufuneka zijonge izinto ezijikelezayo zendlela yokugijima kunye neziqengqelekayo ukuze zibone ukuba azigqwali na kwaye ziqinisekise ukujikeleza okuguquguqukayo. Ngexesha lokufakelwa, amandla kufuneka asetyenziswe ngokulinganayo nangokulinganayo kwisangqa sangaphakathi okanye sangaphandle, kusetyenziswa izixhobo ezichanekileyo ukuthintela ukungqubana okanye ukuthambeka. Amandla kufuneka afaneleke—ukuba kufuneka uxinzelelo olugqithisileyo, ukuhlanganiswa kufuneka kume ngoko nangoko ukuze kuhlolwe, njengoko oku kubonisa ukungalingani okukhulu okunokonakalisa ibheringi kwaye kubeke esichengeni indibano yonke.

Ngokudibanisa ubunzulu besakhiwo esingagungqiyo se-ZHHIMG® granite crossbeam kunye nezi mfuno zokudibanisa eziqinileyo, iinjineli ziqinisekisa ukuba umatshini ophumayo usebenza ngokuchaneka okuzinzileyo, kwinqanaba le-nanometer elilindelweyo lishishini lehlabathi elichaneke kakhulu.

Ixesha lokuthumela: Novemba-12-2025