Izinto eziQinisekisiweyo zeGranite: Izinto ekufuneka ziqwalaselwe xa zidityaniswe kumatshini weVMM

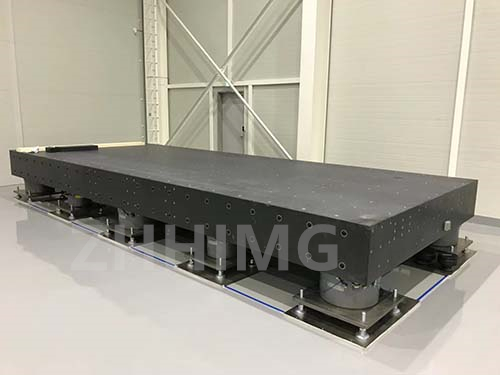

Xa kufikwa ekudibaniseni izinto ezichanekileyo zegranite kumatshini we-VMM (Vision Measuring Machine), kufuneka kuqwalaselwe izinto ezininzi ukuqinisekisa ukusebenza kakuhle kunye nokuchaneka. Igranite lukhetho oludumileyo lwezinto ezichanekileyo ngenxa yokuzinza kwayo okugqwesileyo, ukuqina okuphezulu, kunye nokumelana nokuguguleka kunye nokubola. Nangona kunjalo, ukuze kusetyenziswe ngokupheleleyo iingenelo zegranite kumatshini we-VMM, ezi zinto zilandelayo kufuneka ziqwalaselwe:

1. Umgangatho wezinto ezisetyenzisiweyo: Umgangatho wegranite esetyenziselwa izinto ezichanekileyo ubalulekile. Igranite esemgangathweni ophezulu enoxinano olufanayo kunye noxinzelelo oluncinci lwangaphakathi lubalulekile ekufezekiseni imilinganiselo echanekileyo nethembekileyo kumatshini we-VMM.

2. Uzinzo lobushushu: Uzinzo lobushushu lweGranite luyinto ephambili ekufuneka iqwalaselwe, njengoko ukuguquguquka kobushushu kunokuchaphazela ukuchaneka kobukhulu bezinto. Kubalulekile ukukhetha igranite eneempawu zokwandiswa kobushushu obuphantsi ukuze kuncitshiswe impembelelo yokutshintsha kobushushu ekusebenzeni komatshini.

3. Iimpawu zokuqina kunye nokufuma: Iimpawu zokuqina kunye nokufuma zezixhobo zegranite zidlala indima ebalulekileyo ekunciphiseni ukungcangcazela nokuqinisekisa imilinganiselo ezinzileyo. Ukudibanisa igranite nokuqina okuphezulu kunye neempawu zokucima ezigqwesileyo kunokuphucula ukuchaneka kunye nokuphindaphinda komatshini we-VMM.

4. Ukugqitywa komphezulu kunye nokuthamba: Ukugqitywa komphezulu kunye nokuthamba kwezinto zegranite kubalulekile ekufezekiseni imilinganiselo echanekileyo. Ingqwalasela enzulu kufuneka inikwe kwiinkqubo zokuvelisa ukuqinisekisa ukuba umphezulu wegranite ugudile, uthe tyaba, kwaye awunazo iziphene ezinokuthi ziphazamise ukuchaneka komatshini weVMM.

5. Ukufakela kunye nokulungelelanisa: Ukufakela kunye nokulungelelanisa ngokufanelekileyo izinto ezichanekileyo zegranite ngaphakathi komatshini we-VMM kubalulekile ekugcineni ukuthembeka kokulinganisa. Iindlela zokufakela ngokuchanekileyo kunye neenkqubo zokulungelelanisa ngononophelo kufuneka zisetyenziswe ukuqinisekisa ukuba izinto zegranite zisebenza kakuhle ngaphakathi komatshini.

6. Izinto eziqwalaselwayo kwiNdalo: Indawo yokusebenza komatshini we-VMM kufuneka iqwalaselwe xa kuhlanganiswa izinto ezichanekileyo zegranite. Izinto ezinje ngokulawula ubushushu, amanqanaba okufuma, kunye nokuvezwa kwizinto ezingcolisayo kufuneka zilawulwe ukuze kulondolozwe uzinzo olulinganayo kunye nokusebenza kwezinto zegranite.

Ukuqukumbela, ukudibanisa izinto ezichanekileyo zegranite kumatshini we-VMM kufuna ingqalelo enzulu kumgangatho wezinto eziphathekayo, uzinzo lobushushu, ukuqina, ukugqitywa komphezulu, ukufakwa, ukulungelelaniswa, kunye neemeko zokusingqongileyo. Ngokujonga ezi ngqwalasela, abavelisi banokwenza ngcono ukusebenza kunye nokuchaneka koomatshini babo be-VMM, ekugqibeleni baphucule umgangatho kunye nokuthembeka kweenkqubo zabo zokulinganisa.

Ixesha leposi: Julayi-02-2024