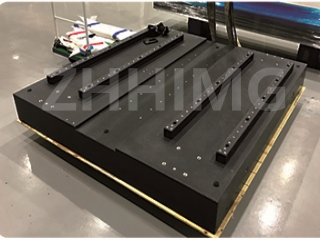

Ipleyiti yomphezulu wegranite sisixhobo esichanekileyo esenziwe ngegranite enoxinano oluphezulu, eyaziwa ngokuzinza kwayo, ukuqina kwayo, kunye nokuba tyaba. Isetyenziswa kakhulu kwimveliso, i-metrology, kunye nolawulo lomgangatho, isebenza njengeqonga elisisiseko lokuqinisekisa ukuchaneka kwimilinganiselo ebalulekileyo kunye nokuhlolwa. Nazi izicelo zayo eziphambili kunye neenzuzo:

1. Ukulinganisa ngokuchanekileyo kunye nokulinganisa

Indima ephambili yepleyiti yomphezulu wegranite kukubonelela ngomphezulu othe tyaba nozinzileyo wereferensi yezixhobo zokulinganisa kunye nezinto ezisetyenziswayo. Iimpawu zayo ezisisiseko—ezifana nokwanda okuphantsi kobushushu, ukumelana nokugqwala, kunye nokuguquguquka okuncinci ngokuhamba kwexesha—zenza ukuba ilungele:

Izixhobo zokulinganisa: Izixhobo ezifana nee-micrometer, izalathisi zokudayela, kunye noomatshini bokulinganisa abalungelelanisiweyo (ii-CMM) ziyavavanywa kwaye zilinganiswe kwipleyiti ukuqinisekisa ukuba zinika ukufundwa okuchanekileyo.

Ukuqinisekisa ubungakanani benxalenye: Abavelisi babeka izinto ngqo kwipleyiti ukujonga ukuba zithe tyaba, zisikwere, okanye ziyafana besebenzisa iigeyiji okanye ii-laser interferometers. Umzekelo, kwi-aerospace, ii-turbine blades ziyahlolwa ukuze kujongwe ukuphambuka okuncinci kwiinkcukacha zoyilo.

Ukuchaneka kwenqanaba le-Micrometer: Iipleyiti zezinga eliphezulu (umz., iBanga A) zinokufikelela ekunyamezeleni ukuthamba okuqinileyo njenge-±0.00008 intshi, nto leyo eyenza ukuba zingabi yimfuneko kumashishini afana nokuveliswa kwe-semiconductor, apho ukuchaneka kubaluleke kakhulu.

2. Ulawulo loMgangatho kunye noHlolo

Kwimigca yemveliso, iipleyiti zomphezulu wegranite zisebenza njengeendawo zokulawula umgangatho ukuqinisekisa ukuba izixhobo ziyahlangabezana nemigangatho engqongqo:

Uvavanyo lokugqitywa komphezulu: Iindawo ezisetyenzisiweyo (umz., iibhloko zeinjini, iigiya) zibekwa kwipleyiti ukujonga uburhabaxa okanye ukungagqibeleli komphezulu kusetyenziswa iiprofilometers okanye ii-optical comparators.

Ukuqinisekiswa kokuhlanganiswa: Ngexesha lokuhlanganiswa kwezixhobo (umz., kwi-robotics okanye kwizixhobo zonyango), ipleyiti iqinisekisa ukuba iindawo zilungelelaniswe ngokuchanekileyo, nto leyo enciphisa iimpazamo ezinokubangela ukuba imveliso ingaphumeleli.

Ukuthobela imigangatho: Amashishini athobela i-ISO, i-ASME, okanye imigangatho yeemoto (umz., i-IATF 16949) axhomekeke kwiipleyiti zegranite ukuqinisekisa imilinganiselo kunye nokugcina ukuthotyelwa kwemithetho.

3. Ukuseta Izixhobo kunye neZixhobo

Iipleyiti zomphezulu wegranite zenza kube lula ukuseta izixhobo zoomatshini kunye nezixhobo:

Ukulungelelaniswa kwejig kunye nezixhobo: Iingcali zoomatshini zisebenzisa ipleyiti ukubeka izixhobo zokubhola, zokusila, okanye zokusila ngokuchanekileyo, ukuqinisekisa ubungakanani obufanayo bezinto kuzo zonke iibhetshi.

Ukulinganiswa kwezixhobo zokusika: Izixhobo ezifana nee-end mills okanye ii-lathe bits zilungiswa kwipleyiti ukuze kufumaneke ii-engile kunye nokuphakama okuchanekileyo ngaphambi kokusetyenziswa, oku kunciphisa inkunkuma yezinto kunye nokuphucula ukusebenza kakuhle.

4. Izicelo zeLebhu kunye noPhando

Kuphando lwesayensi nophuhliso (R&D), iipleyiti zegranite zibonelela ngeqonga elizinzileyo leemvavanyo ezibuthathaka:

Useto lwe-optical kunye ne-laser: Kwiilabhoratri zefiziksi, iipleyiti zixhasa ii-interferometers okanye ii-spectrometers, apho ukungcangcazela okanye utshintsho lobushushu lunokuphazamisa iziphumo.

Uvavanyo lwezinto: Iisampulu zovavanyo lobunzima (umz., uvavanyo lweRockwell okanye lweVickers) zibekwa epleyitini ukuqinisekisa ukulayishwa okufanayo kunye nokuqokelelwa kwedatha ngokuchanekileyo.

5. Iingenelo ngaphezu kweePleti zesinyithi

Iimpawu ezikhethekileyo zeGranite ziyenza ibonakale inomtsalane kuneepleyiti zentsimbi okanye zesinyithi:

Uzinzo lobushushu: I-Granite ifunxa ubushushu kancinci kwaye inomlinganiselo ophantsi wokwanda kobushushu, nto leyo eyenza ukuba ithembeke kumaqondo obushushu atshintshatshintshayo (umz., iindawo ze-车间).

Ayinamagnethi kwaye ayimelani nomhlwa: Ayizukuphazamisana nezixhobo zemagnethi okanye yonakale xa ibekwe kwiioyile, izinto ezipholisayo, okanye ukufuma.

Ubude bexesha elide: Ngononophelo olufanelekileyo, ipleyiti yegranite ingahlala amashumi eminyaka ngaphandle kokulahlekelwa bububhetyebhetye bayo, nto leyo enika imbuyekezo ephezulu kutyalo-mali.

Isiphelo

Ipleyiti yomphezulu wegranite ayisiyonto nje "yesilayidi esithe tyaba"—lilitye lesiseko lokwenziwa ngokuchanekileyo kunye nokuqinisekiswa komgangatho. Nokuba isetyenziselwa ukulinganisa izixhobo, ukuhlola izinto ezibalulekileyo, okanye ukuxhasa iimvavanyo ezintsonkothileyo, ukuzinza kwayo kunye nokuchaneka kwayo kwenza ukuba ingabi nakutshintshwa kumashishini apho neempazamo ezincinci zinokuba nemiphumo ebalulekileyo. Ngokutyala imali kwipleyiti yegranite esemgangathweni ophezulu, amashishini anokuphucula imveliso, anciphise iziphene, kwaye agcine ukuthembana kwabathengi abafuna ukugqwesa.

Ixesha leposi: Meyi-23-2025