I-CNC (ulawulo lwamanani ekhompyutheni) izixhobo zoomatshini zisetyenziswa kumashishini ahlukeneyo afana nokuvelisa, i-aerospace, i-automotive, kunye nezinye ezininzi. Aba matshini basetyenziselwa ukusika, ukubumba, kunye nokukrola izinto ezifana nentsimbi, iplastiki, umthi kunye negranite. Oomatshini be-CNC bafuna isiseko esomeleleyo sokubonelela ngokuzinza kunye nokuchaneka, yingakho isiseko se-granite sisetyenziswa njengenxalenye ebalulekileyo kwizixhobo zomatshini we-CNC.

I-Granite yaziwa ngokugqwesa kozinzo lwe-dimensional kunye nokuchasana nokuguqulwa, okwenza kube yinto efanelekileyo yokusetyenziswa ekwakhiweni kweziseko zezixhobo zoomatshini. Ukuzinza kwegranite kuqinisekisa ukuba ukuhamba komtshini ngexesha lemisebenzi yokusika akuchaphazeli ukuchaneka kokusika. Ubunzima obuphezulu kunye nesakhiwo esifanayo se-granite siqinisekisa ukuphazamiseka okuphantsi kunye nokuzinza okuphezulu naphantsi kokushisa okukhulu kunye noxinzelelo.

Ukusetyenziswa kwegranite njengesiseko kukwabonelela ngezinga eliphezulu lokudambisa koomatshini be-CNC. Iimpawu zegranite zendalo ezithintela ukothuka zivumela oomatshini ukuba basebenze ngesantya esiphezulu ngaphandle kokungcangcazela okanye ukuyeka ngokukhawuleza, ukuphucula ukuchaneka nokuchaneka. Ukushukuma okubangelwa yinkqubo yokusika kunokubangela ukunyakaza okungafunekiyo kumatshini, kodwa ngenxa yeempawu zokudambisa igranite, ezi ntshukumo ziyancitshiswa okanye zipheliswe ngokupheleleyo.

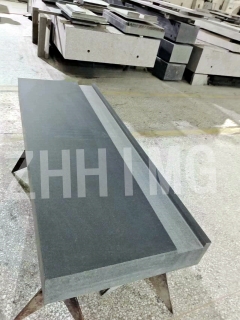

Ngaphezu koko, isiseko segranite senza izixhobo zomatshini we-CNC zibe nendawo echanekileyo kunye nenqanaba lokusebenza. Igranite inoburhabaxa obuphantsi kakhulu kunye nokuphakama okuphezulu, okuthetha ukuba umphezulu wegranite usicaba ukuya kwii-microns ezimbalwa. Xa ibhedi yomatshini ifakwe ngokufanelekileyo phezu kwesiseko segranite, ivumela ukuba umatshini ube nendawo yokusebenza ezinzileyo nechanekileyo. Oku kuqinisekisa ukuba isixhobo somatshini sisika ngokweenkcukacha ezifunekayo.

Enye inzuzo yokusebenzisa i-granite kwisiseko soomatshini be-CNC kukuba inika ukuchasana okugqwesileyo kwiikhemikhali kunye nokubola. Igranite iyaxhathisa kwiiasidi ezininzi, iziseko, kunye nezinyibilikisi, nto leyo eyenza ukuba ibe yeyona nto ifanelekileyo yokusebenzisa kwiindawo ezirhabaxa. Oku kubalulekile kumashishini apho iikhemikhali kunye nee-oyile zisetyenziswa ngokuqhelekileyo, njengoko kunciphisa amathuba okuba nomhlwa kunye nongcoliseko kumphezulu wesixhobo somatshini.

Ukuqukumbela, isiseko segranite siyinxalenye ebalulekileyo kwizixhobo zomatshini we-CNC. Iqinisekisa ukuzinza komatshini ngexesha lenkqubo yokusika, ukunciphisa ukungcangcazela, ukubonelela ngenqanaba lomsebenzi, kunye nokuphucula ukuchaneka nokuchaneka. Iinzuzo zokusebenzisa i-granite njengesiseko somatshini zenza ukuba zidume kumashishini ahlukeneyo okuvelisa kunye nokuvumela izixhobo zomatshini ukuba zisebenze kumanqanaba aphezulu okusebenza kunye nokuchaneka.

Ixesha lokuposa: Mar-26-2024