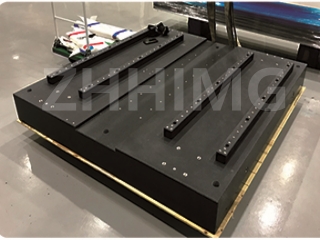

I-Granite lilitye lendalo elineendlela ezahlukeneyo zobuhle kunye nokusetyenziswa okusebenzayo, kubandakanya ukusetyenziswa kwalo kwimveliso yeeCoordinate Measuring Machines (CMM). Ii-CMM zizixhobo zokulinganisa ezichanekileyo kakhulu ezenzelwe ukumisela ijometri kunye nobukhulu bento. Zisetyenziswa kumashishini ahlukeneyo, kuquka i-aerospace, iimoto, ubunjineli bemishini, nokunye.

Ukubaluleka kokuchaneka kokulinganisa i-CMM akunakugqithiswa, njengoko umahluko nokuba yi-intshi ezimbalwa unokwenza umahluko phakathi kwemveliso esebenzayo kunye neyona inesiphako. Ke ngoko, izinto ezisetyenziselwa ukwakha i-CMM kufuneka zikwazi ukugcina imo yazo kwaye zihlale zizinzile ngokuhamba kwexesha ukuqinisekisa ukulinganiswa okuchanekileyo nokungaguquguqukiyo. Ngaphezu koko, izinto ezisetyenzisiweyo kufuneka zikwazi ukumelana neemeko zokusebenza ezinzima.

Kweli nqaku, siza kuxoxa ngesizathu sokuba i-granite ibe yinto efanelekileyo yokwakha i-CMM, kwaye zeziphi iimpawu ezenza ukuba ilungele umsebenzi.

1. Uzinzo:

Enye yezona mpawu zibalulekileyo zegranite kukuzinza kwayo. Igranite yinto exineneyo nengangeni nto ekwaziyo ukumelana nokuguquguquka kwaye ayikhuli okanye inciphe xa kutshintshwe ubushushu. Ngenxa yoko, izinto zegranite zibonelela ngozinzo oluhle kakhulu, oluyimfuneko ekufezekiseni amanqanaba aphezulu okuchaneka kwimilinganiselo yeCMM.

2. Ukunciphisa ukungcangcazela okugqwesileyo:

I-granite inesakhiwo esahlukileyo esinika iipropati ezibalaseleyo zokudambisa ukungcangcazela. Ingafunxa ukungcangcazela kwaye ikwahlukanise neqonga lokulinganisa ukuze kufumaneke iziphumo zokulinganisa ezizinzileyo. Ulawulo lokungcangcazela olusebenzayo lubalulekile ekuqinisekiseni ukulinganiswa kwe-CMM esemgangathweni, ngakumbi kwiindawo ezinengxolo. Iipropati zokudambisa ukungcangcazela ze-granite ziyivumela ukuba ihluze ukuphazamiseka okungafunekiyo kwaye iqinisekise iziphumo ezithembekileyo.

3. Ukumelana nokunxitywa:

I-Granite yinto eqinileyo kakhulu enokumelana nokuguga okuza nokusetyenziswa rhoqo kwiindawo zoshishino. Ayikwazi ukukrwela, ukuqhekeka, kunye nokugqwala, nto leyo eyenza ukuba ibe yinto efanelekileyo kwiindawo ze-CMM ezidibana neendawo ezihambayo kunye nee-abrasive agents.

4. Uzinzo lobushushu:

I-granite inomlinganiselo ophantsi wokwanda kobushushu, oko kuthetha ukuba ayikhuli okanye ayinciphisi kakhulu xa kutshintshwe ubushushu. Ngenxa yoko, ingakwazi ukugcina imo yayo, nokuba iphantsi kokuguquguquka kobushushu, okuvumela ii-CMM ukuba zivelise iziphumo ezichanekileyo kuluhlu olubanzi lobushushu obusebenzayo.

5. Ubuchule bokusebenza:

I-Granite yinto enzima neyinzima ukusebenza ngayo. Ifuna ubuchule obuphezulu bobuchwephesha kunye nezixhobo ezikhethekileyo ukuyibumba nokuyigqiba ngokuchanekileyo. Nangona kunjalo, ubuchule bayo bokuyilungisa buvumela ukucutshungulwa ngokuchanekileyo kwezinto ze-granite, nto leyo ephumela kwiimveliso ezigqityiweyo ezikumgangatho ophezulu.

Ukuqukumbela, igranite yinto efanelekileyo yokwakha iCMM ngenxa yozinzo lwayo oluphezulu, iimpawu zokudambisa ukungcangcazela, ukumelana nokuguguleka, uzinzo lobushushu, kunye nokusebenza kakuhle koomatshini. Iigranite CMMs zakhiwe ukuze zikwazi ukumelana neemeko ezinzima zokusebenza kwaye zibonelele ngokulinganisa okuchanekileyo. Ukongeza, zibonelela ngobomi benkonzo ende, ukusebenza ngaphandle kokugcinwa, kunye nozinzo, nto leyo ezenza zibe lutyalo-mali olunobulumko nolungabizi kakhulu kumashishini amaninzi.

Ixesha lokuthumela: Epreli-02-2024